Preparation method of graphene field effect transistor based on bubbling

A field-effect transistor, graphene technology, applied in transistors, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve problems such as difficult control, high cost, complex process, etc., to avoid damage to the channel, avoid pollution, The effect of reducing manufacturing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

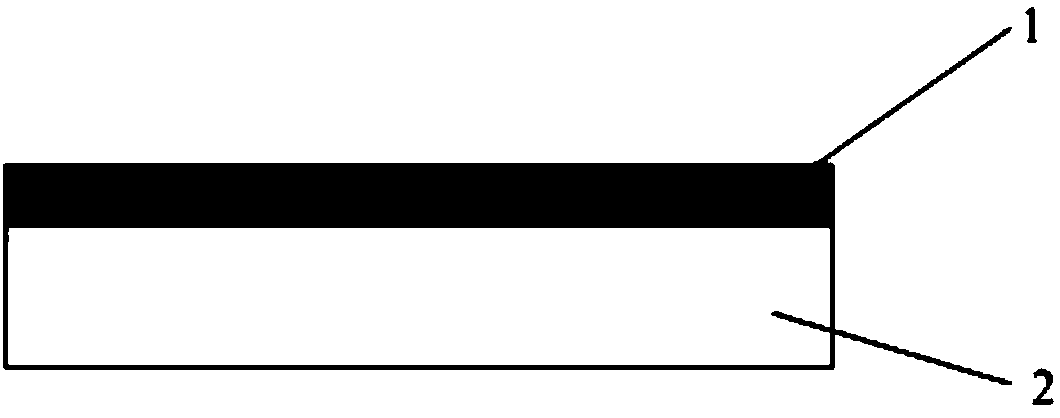

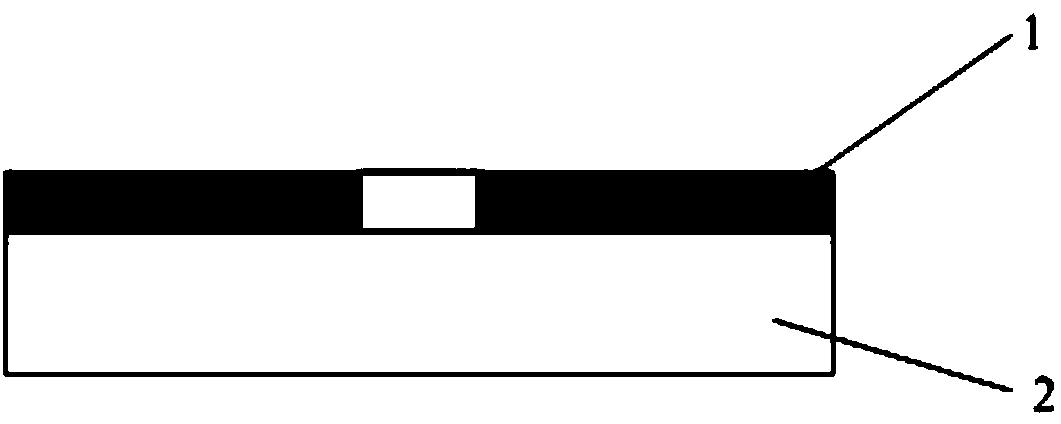

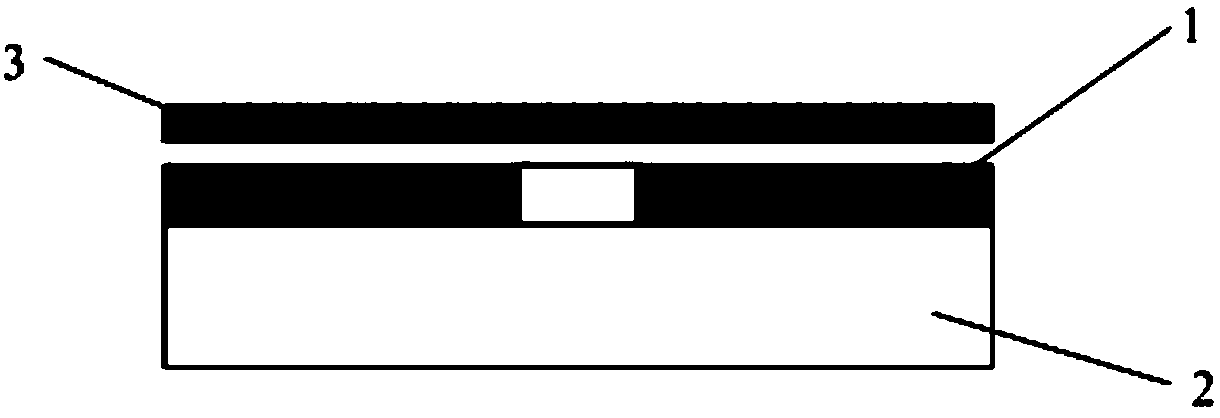

[0022] The present invention first forms SiO with a thickness of 300 nm on the Si substrate by thermal oxidation. 2 oxide layer, then the SiO 2 For surface pretreatment, bake in an oven at 150-200°C for 15-30 minutes to keep the surface dry and clean, and apply a layer of HMDS chemical adhesion enhancer to prevent it from falling off. Uniformly spin-coat photoresist and dry photoresist to cure the glue, then expose and develop to realize pattern transfer. SiO on non-spin-coated photoresist 2 The step of forming small holes by etching on the surface: using reactive ion etching method, on SiO without spin-coated photoresist 2 The surface is etched to form a 250nm deep hole with a diameter of 10um, and the photoresist is cleaned with acetone vapor, and then the sample is cleaned with ethanol and deionized water, such as figure 2 The schematic diagram of the hole structure is shown. The mechanical exfoliation method is used to prepare double-layer graphene using a special 3M ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com