Preparation method of lithium ion battery solid electrolyte interphase, and lithium ion battery

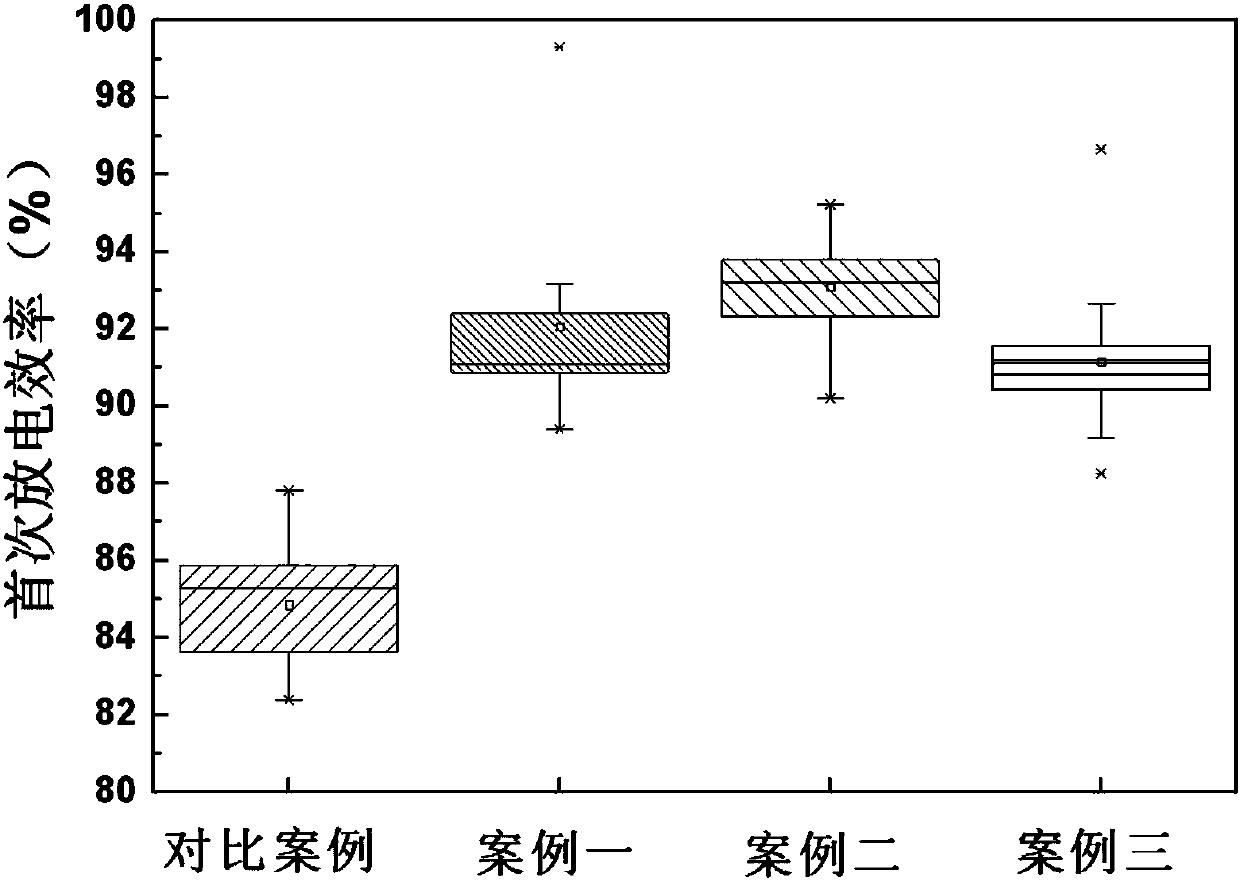

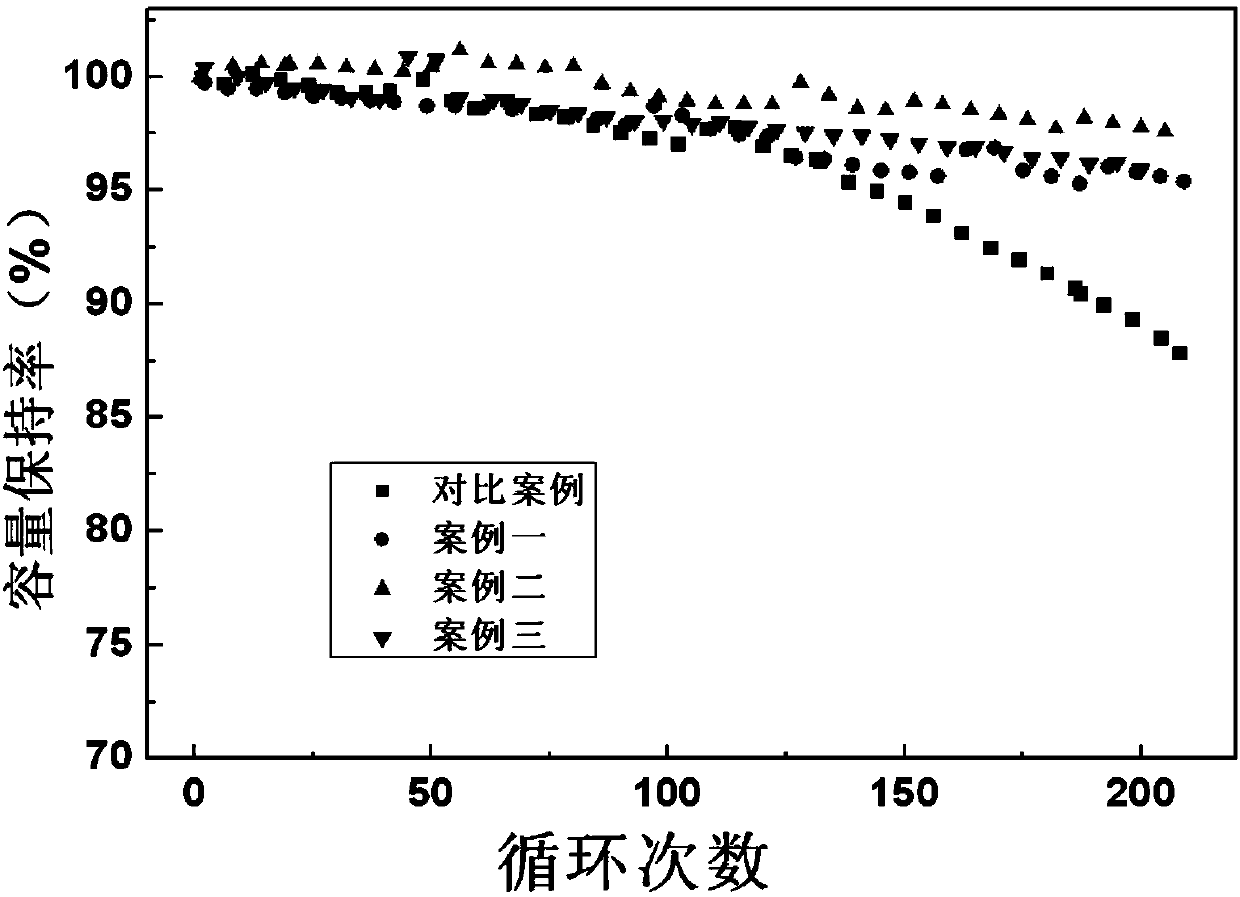

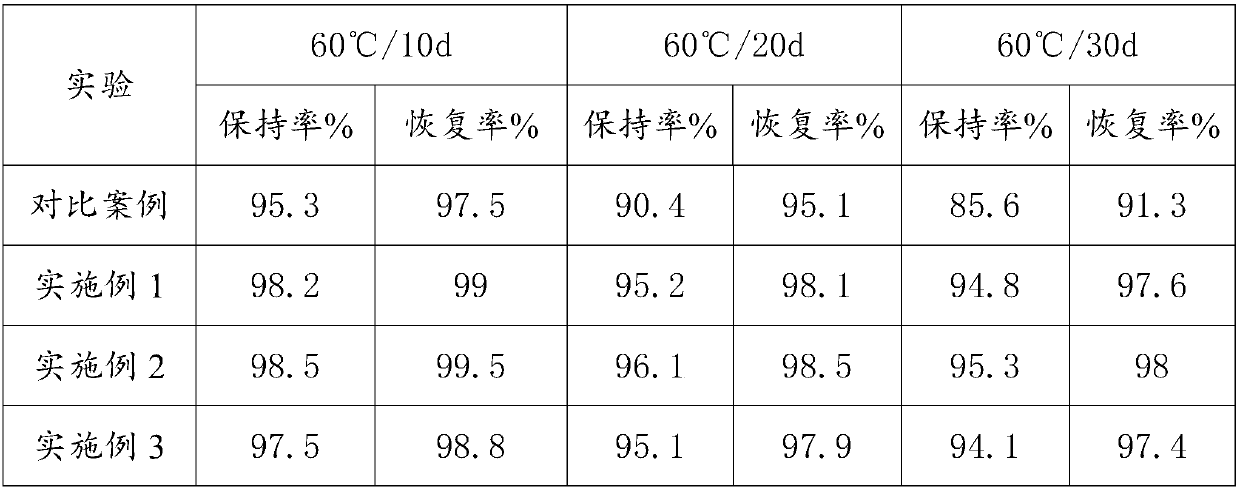

A solid electrolyte membrane, lithium ion battery technology, applied in non-aqueous electrolyte storage batteries, electrolyte storage battery manufacturing, secondary batteries, etc. Discharge efficiency and other issues, to achieve the effect of good transmission of lithium ions and insulation of electronics, good cycle performance and storage performance, and improved first charge and discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The present invention provides a kind of preparation method of lithium ion battery solid electrolyte membrane, comprises the following steps:

[0016] Step 1: Negative electrode homogenate preparation: Weigh graphite, conductive agent and binder according to a certain mass ratio, then add deionized water, and disperse the negative electrode homogenate with a mechanical stirring disperser;

[0017] Step 2: Preparation of organic solution electroplating cell: weigh lithium salt, organic solvent and additives according to a certain mass ratio, and prepare an organic solvent electrolytic cell;

[0018] Step 3: After sieving the negative electrode homogenate in step 1, evenly coat it on the surface of the current collector copper foil and dry it to make a primary negative electrode sheet; and

[0019] Step 4: Immerse the primary negative electrode sheet obtained in step 3 into the organic solution electroplating pool described in step 2, electroplate a layer of organic film ...

Embodiment 1

[0029] 1) Negative electrode homogenate preparation: Weigh 94% natural graphite, 2.5% SP, 1.5% CMC, 2% SBR according to a certain dry powder mass, first dissolve CMC in deionized water to prepare a glue, and then add SP and natural graphite in sequence and SBR, using a mechanical stirring disperser to disperse the negative electrode homogenate, the solid content of the negative electrode homogenate is 45% to 55%, and the viscosity is 600 to 1500mPa.s;

[0030] 2) Preparation of organic solution electroplating pool: weigh lithium salt LiBOB:LiPF according to a certain mass ratio 6 :LiBF 4 :LiAsF 6 =1:1:0.5:0.5, the total lithium salt mass accounts for 13% of the quality of the organic solution electroplating pool; by weighing EC, DMC, EMC organic solvents in a mass ratio of 1:1:1, the total organic solvents The mass accounts for 85% of the quality of the organic solution electroplating pool; the VC, LiODFB, HDMS, TTFP, BP additives are weighed in a mass ratio of 1:1:1:1:1, an...

Embodiment 2

[0034] 1) Negative electrode homogenate preparation: Weigh 94% natural graphite, 2.5% SP, 1.5% CMC, 2% SBR according to a certain dry powder mass, first dissolve CMC in deionized water to prepare a glue, and then add SP and natural graphite in sequence and SBR, using a mechanical stirring disperser to disperse the negative electrode homogenate, the solid content of the negative electrode homogenate is 45% to 55%, and the viscosity is 600 to 1500mPa.s;

[0035] 2) Preparation of organic solution electroplating pool: weigh lithium salt LiBOB:LiPF according to a certain mass ratio 6 :LiBF 4 =1:2:0.5, the total lithium salt mass accounts for 14% of the quality of the organic solution electroplating pool; it is 0.5:0.5:1:1 to weigh EC, PC, DMC, EMC organic solvents according to the mass ratio, the total The mass of the organic solvent accounts for 84.5% of the mass of the organic solution electroplating pool; VC, LiODFB, HDMS, and BP additives are weighed in a mass ratio of 1:1:1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com