Preparation method of aqueous nano-antibacterial photocatalytic titanium oxide composite sol

A composite sol, antibacterial titanium technology, applied in the directions of botanical equipment and methods, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of increased cost, high cost, cumbersome process, etc., to save wastewater discharge and save The use of alkali, the effect of uniform particle morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The synthetic method of described aqueous nano antibacterial titanium oxide composite sol according to the present invention comprises the following steps:

[0033] (1) Acid hydrolysis

[0034] Heating and dissolving ilmenite with concentrated sulfuric acid with a concentration of more than 80wt% by weight, the mass ratio of ilmenite to concentrated sulfuric acid is 1:0.5 to 1:6, the reaction is intense and rapid, generally completed within 5 to 30 minutes, the reaction The highest temperature reaches 250°C, and the obtained solid phase deposit is soaked with 5-10 times the volume of water to obtain titanium liquid;

[0035] (2) Purification of titanium liquid

[0036] Filtering the titanium solution in step (1) to remove insoluble slag, freezing and recrystallizing to remove ferrous sulfate by filtration to obtain a titanium-containing precursor solution;

[0037] (3) Titanium peroxide complexation

[0038] The precursor solution in step 2) is diluted with water to ...

Embodiment 1

[0047] 1) heating and dissolving ilmenite with concentrated sulfuric acid with a mass percentage concentration of 85wt%, wherein the mass ratio of ilmenite to sulfuric acid is 1:2, and the obtained solid phase deposit is obtained by leaching with 7.5 times the volume of water to obtain titanium liquid, Then filter to remove insoluble slag;

[0048] 2) freezing and recrystallizing the titanium solution in step 1) to remove ferrous sulfate by filtration to obtain a titanium-containing precursor solution;

[0049] 3) Dilute the precursor solution in step 2) to titanium oxysulfate (TiOSO 4 ) is a 1wt% solution by mass percent; 200g of the 1wt% titanyl sulfate solution is taken to add 121g of 1wt% ZnO by mass percent 2 Suspension, wherein the molar ratio of Ti:Zn is about 1:1;

[0050] 4) Add 0.1 g of Fe(NO 3 ) 2 Powder, reflux at 100°C for 30 minutes to obtain a yellow sol;

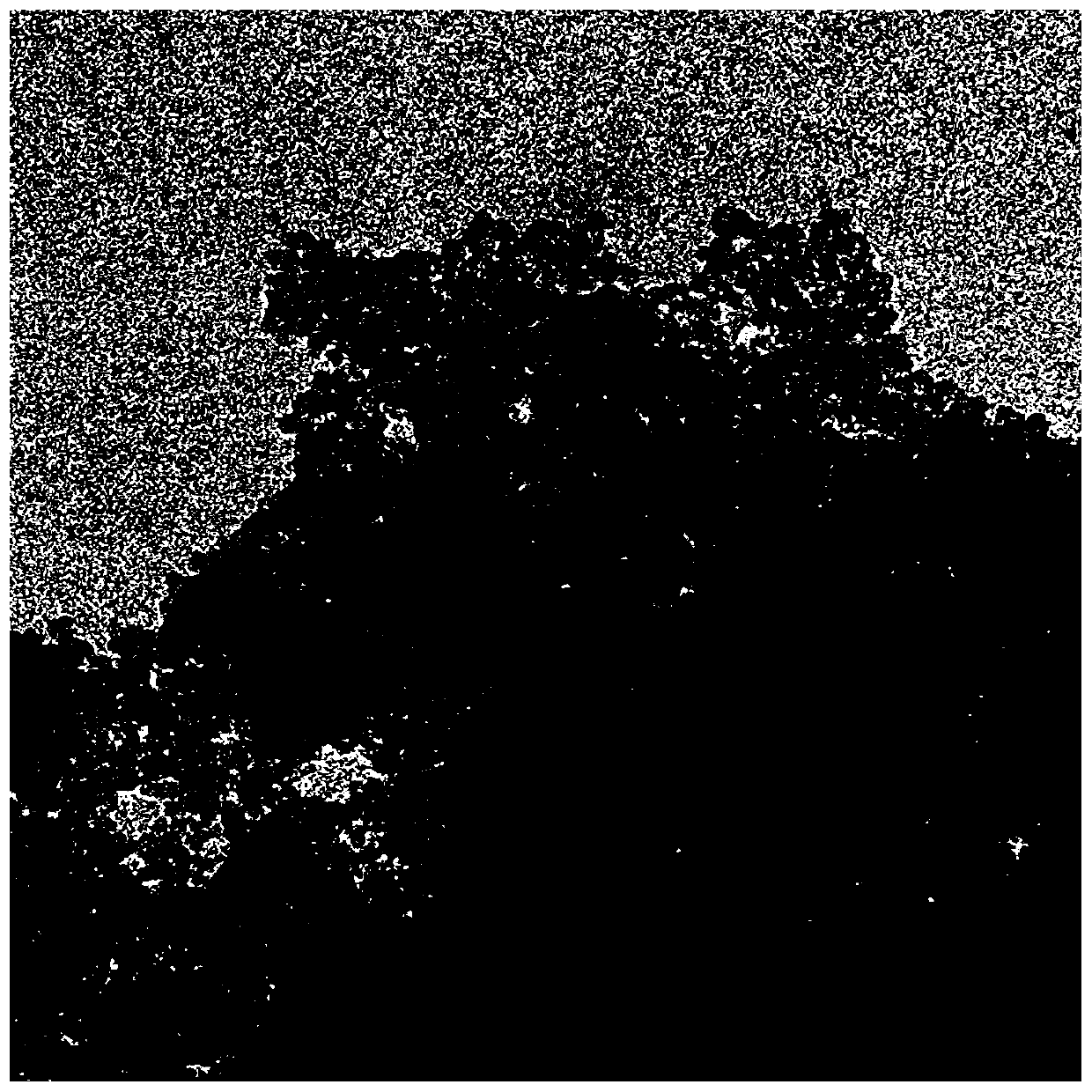

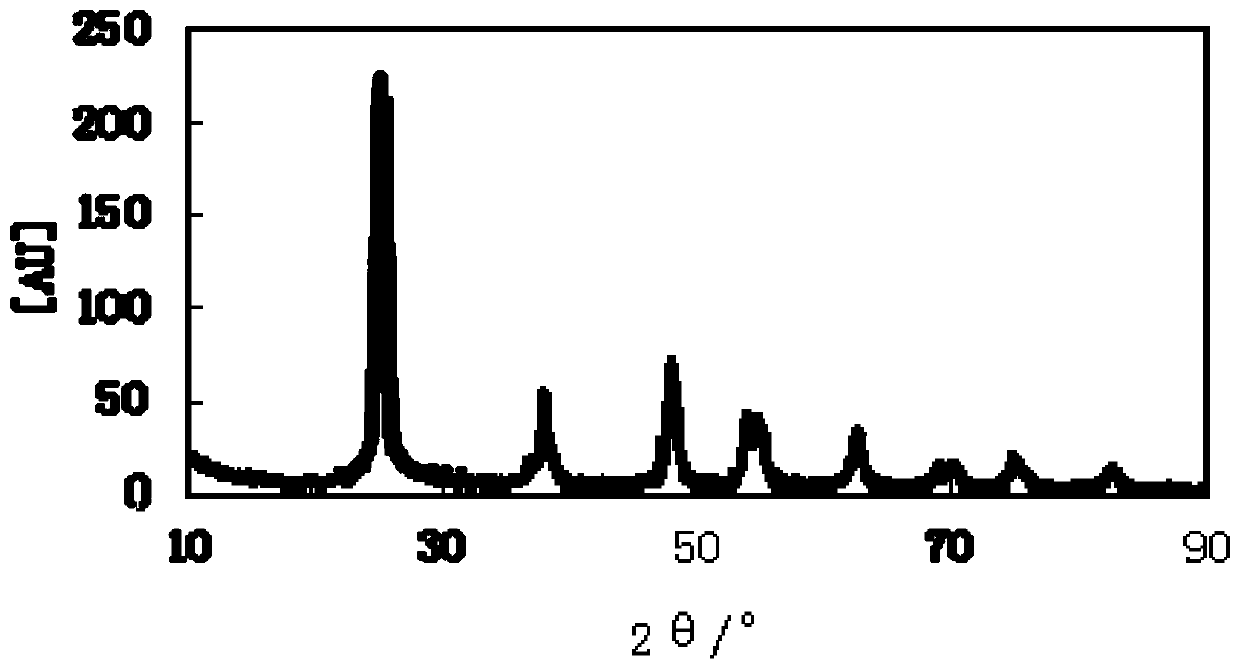

[0051] Product results characterized by TEM as nanoparticles, see attached figure 1 . The obtained ...

Embodiment 2

[0055] Titanium oxide product sol was prepared in the same manner as in Example 1 except that the mass ratio of ilmenite to concentrated sulfuric acid was 1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com