A kind of preparation method of furan resin for 3D printing

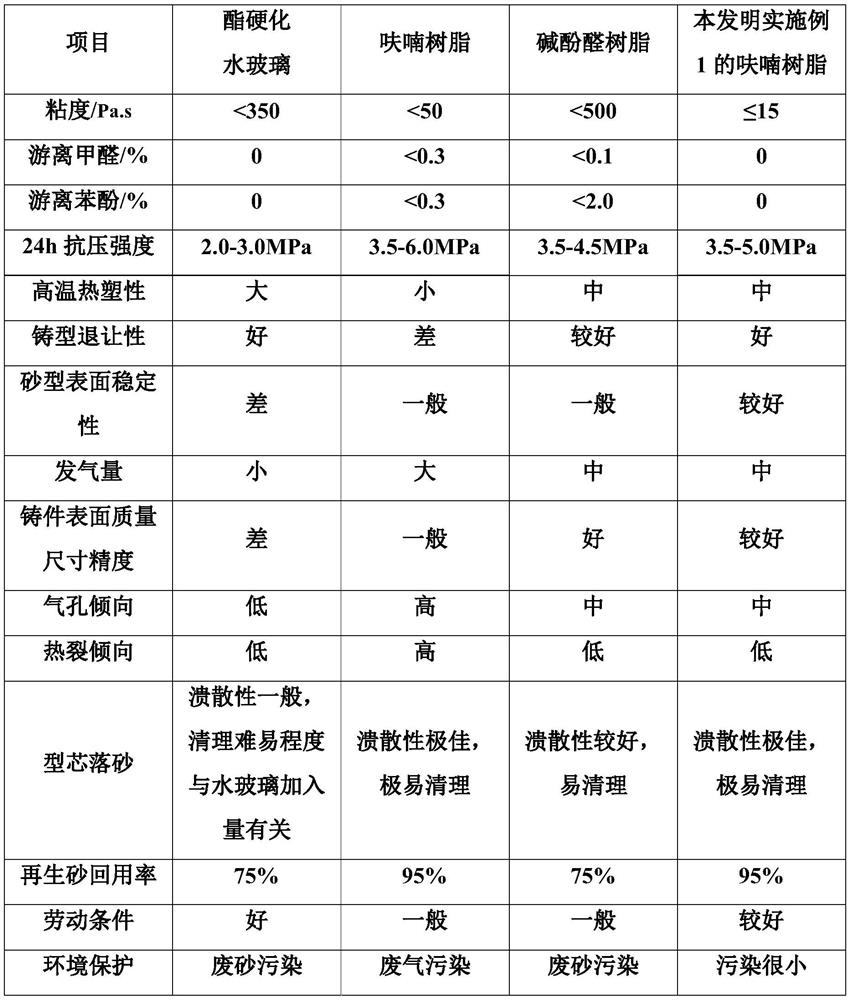

A furan resin, 3D printing technology, applied in the field of organic chemistry, can solve the problem of few binders in 3D sand printing, and achieve the effect of environmental friendly strength, obvious secondary hardening characteristics, and easy reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

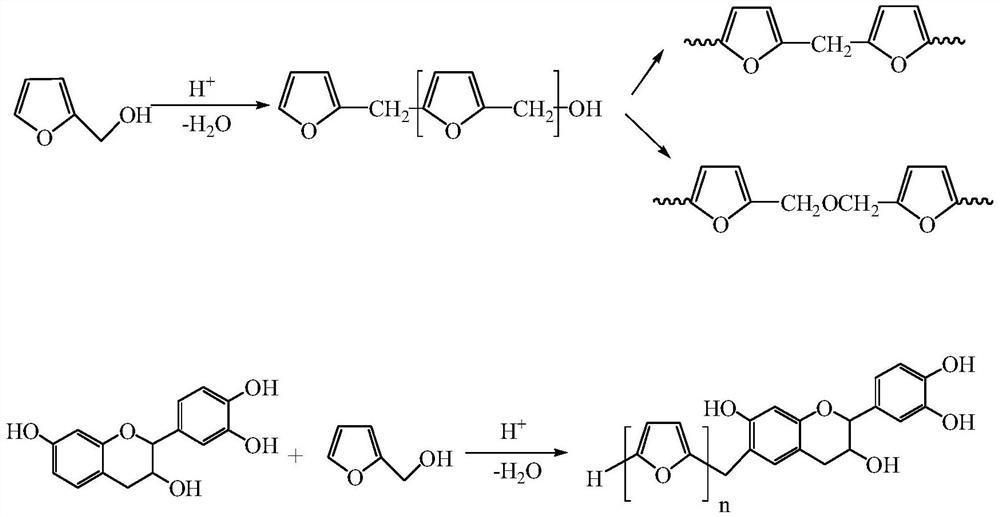

Method used

Image

Examples

Embodiment 1

[0037] (1) Tannic acid furfuryl alcohol prepolymer treatment: Add 200g furfuryl alcohol and 30g tannic acid into the reaction kettle, adjust the pH to 4.1 with 0.28g hydrochloric acid, heat up to 100-105°C, keep stirring for 3 hours; cool down to Dehydration under reduced pressure at 60°C and a vacuum of -0.09MPa until the water content is below 0.5%, to obtain a tannic acid furfuryl alcohol prepolymer, a mixture of furfuryl alcohol and tannic acid.

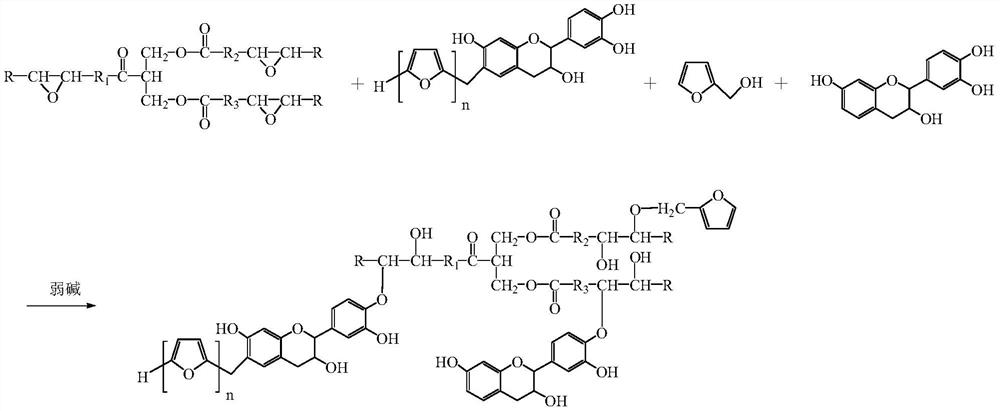

[0038] (2) Epoxy vegetable oil modified tannic acid furfuryl alcohol prepolymer treatment: 200 g of tannic acid furfuryl alcohol prepolymerization solution obtained in step (1) and 3 g of ammonia water are added to the reaction kettle, and the temperature is raised to 120 ° C, and the epoxy large Divide 100g of soybean oil into three equal parts and add it every half an hour. After the addition is complete, continue to keep warm in the range of 120-125°C until the viscosity measured at 20°C reaches 40Pa.s to stop the reaction.

...

Embodiment 2

[0041](1) Tannic acid furfuryl alcohol prepolymer treatment: Add 250g furfuryl alcohol and 40g tannic acid into the reaction kettle, adjust the pH to 3.6 with 0.4g formic acid, heat up to 110-115°C, keep stirring for 3 hours; cool down to Dehydration under reduced pressure at 60°C and a vacuum of -0.09MPa until the water content is below 0.5%, to obtain a tannic acid furfuryl alcohol prepolymer, a mixture of furfuryl alcohol and tannic acid.

[0042] (2) Epoxy vegetable oil modified tannic acid furfuryl alcohol prepolymer treatment: 150 g of tannic acid furfuryl alcohol prepolymerization liquid obtained in step (1), and 8 g of divinylamine are added in the reactor, and the temperature is raised to 130° C. Divide 200g of oxygenated peanut oil into three equal parts and add it every half an hour. After the addition is complete, continue to keep warm in the range of 130-135°C until the viscosity measured at 20°C reaches 40Pa.s to stop the reaction.

[0043] (3) Mixing treatment: ...

Embodiment 3

[0045] (1) Tannic acid furfuryl alcohol prepolymer treatment: Add 200 g of furfuryl alcohol and 40 g of tannic acid into the reaction kettle, adjust the pH to 3.8 with 0.68 g of benzenesulfonic acid, raise the temperature to 140-145°C, and keep stirring for 2 hours; The temperature is lowered to 60° C., and the vacuum degree is -0.09 MPa, and the dehydration is reduced under reduced pressure until the water content is below 0.5%, so as to obtain a mixture of tannic acid furfuryl alcohol prepolymer, furfuryl alcohol and tannic acid.

[0046] (2) Epoxy vegetable oil modified tannic acid furfuryl alcohol prepolymer treatment: 200 g of the tannic acid furfuryl alcohol prepolymerization liquid obtained in step (1), and 6 g of triethylamine are added in the reactor, and the temperature is raised to 140° C. Divide 300g of oxy castor oil into three equal parts and add it every half an hour. After the addition is complete, continue to keep warm in the range of 140-145°C until the viscos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com