A kind of nickel aluminum bronze alloy material and preparation method thereof

An alloy material, nickel-aluminum bronze technology, applied in the field of alloy materials, can solve the problems of poor strength, mechanical properties and tribological properties, and achieve the effect of avoiding the generation of complex phases, high feasibility and good tribological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

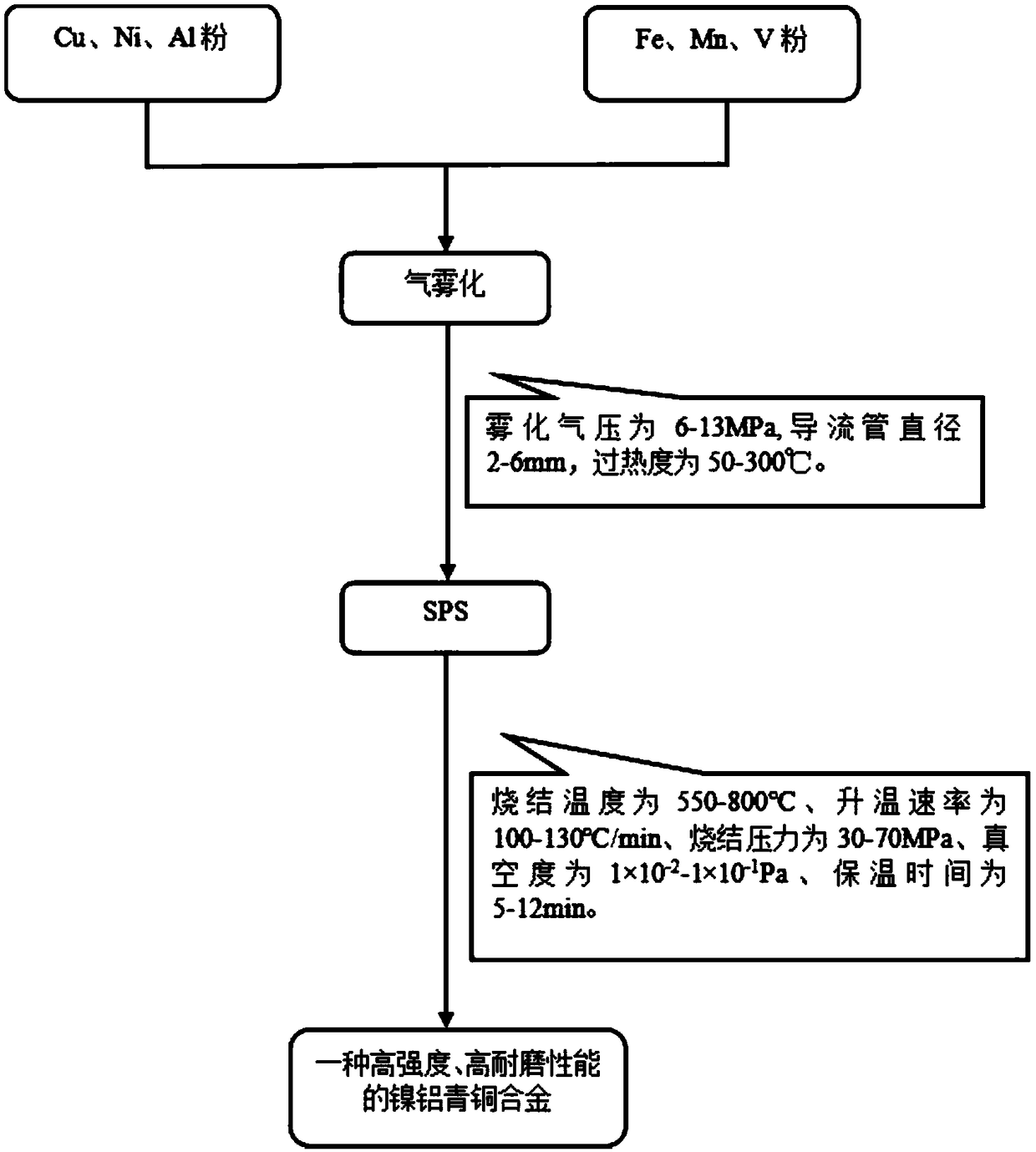

[0037] The preparation method of the nickel aluminum bronze alloy material that the present invention proposes, comprises the steps:

[0038] (1) According to the above-mentioned molar ratio of each element, weigh Cu powder, Al powder, Ni powder, Fe powder, Mn powder and V powder, and mix them to obtain ingredients. The average particle size of the ingredients is 30-50 μm, preferably the average particle size The diameter is 45μm;

[0039] (2) The ingredients are smelted under inert gas protection conditions to obtain a melt; it can be smelted in a high vacuum arc melting system, and the smelting process should reach a vacuum degree of 5×10 before argon protection. -3 Above Pa.

[0040] (3) The melt is gas-atomized, and powders of different particle sizes produced in the gas-atomization process are collected; gas atomization is carried out under inert gas protection conditions, preferably under high-purity argon protection conditions. Atomization: The gas atomization pressur...

Embodiment 1

[0045] like figure 1 Shown, a kind of preparation method of the nickel-aluminum bronze alloy of high strength, high wear resistance, it comprises the steps:

[0046] 1) According to the molar percentage of Cu:Al:Ni:Fe:Mn:V=81.8:9.0:4.0:3.5:0.5:1.2, select Cu powder 14.7g, Al powder 1.6g, Ni powder 0.6g, Fe powder 0.5g , 0.1 gram of Mn powder and 0.2 gram of V powder, the average particle size of the powder is 30-50 μm; Cu powder, Al powder, Ni powder, Fe powder, Mn powder and V powder are mixed to obtain the batching;

[0047] 2) Place the above ingredients in a high vacuum arc melting system for melting, and the vacuum degree will reach 5×10 -3 Pa, filled with argon for protection;

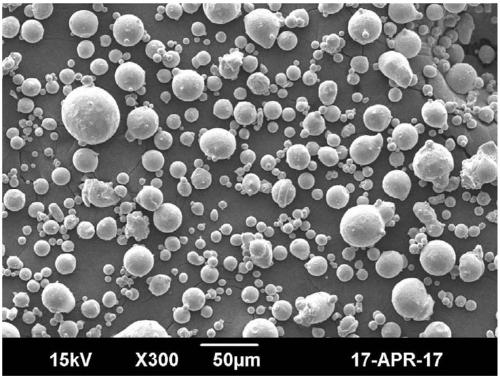

[0048] 3) The melt is introduced into the atomization equipment for atomization. The atomization is carried out with high-purity argon gas. The powder is collected in the powder receiving tank, and the finer powder (particle size<50μm) is collected in the cyclone powder receiving tank.

[004...

Embodiment 2

[0052] 1) According to the molar percentage of Cu:Al:Ni:Fe:Mn:V=81.8:9.0:4.0:3.5:0.5:1.2, select Cu powder 14.7g, Al powder 1.6g, Ni powder 0.6g, Fe powder 0.5g , 0.1 gram of Mn powder and 0.2 gram of V powder, the average particle size of the powder is 30-50 μm; Cu powder, Al powder, Ni powder, Fe powder, Mn powder and V powder are mixed to obtain the batching;

[0053] 2) Place the above ingredients in a high vacuum arc melting system for melting, and the vacuum degree will reach 5×10 -3 Pa, filled with argon for protection;

[0054] 3) The melt is introduced into the atomization equipment for atomization. The atomization is carried out with high-purity argon gas. The powder is collected in the powder receiving tank, and the finer powder (particle size<50μm) is collected in the cyclone powder receiving tank.

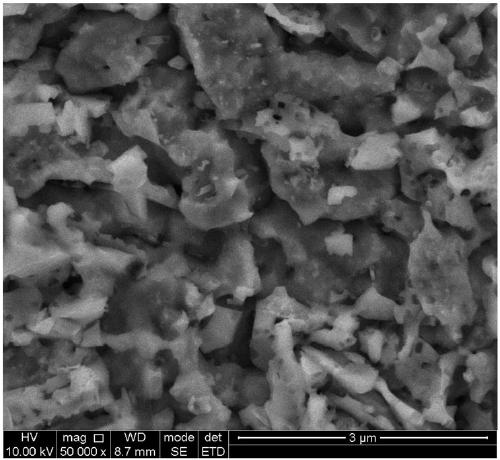

[0055] 4) The nickel-aluminum-bronze alloy was obtained by spark plasma sintering the finer powder prepared by the above gas atomization. -2 Pa, the holding time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com