Sodium storage serving high area-capacity for direct growth of three-dimensional nanoarray electrodes

A three-dimensional nano-array technology, which is applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of low electrode material load, tap density reduces the overall tap density of the electrode, and difficulty in charge transfer, and achieves low cost and high-quality equipment. and the effect of simple production process and easy control of preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

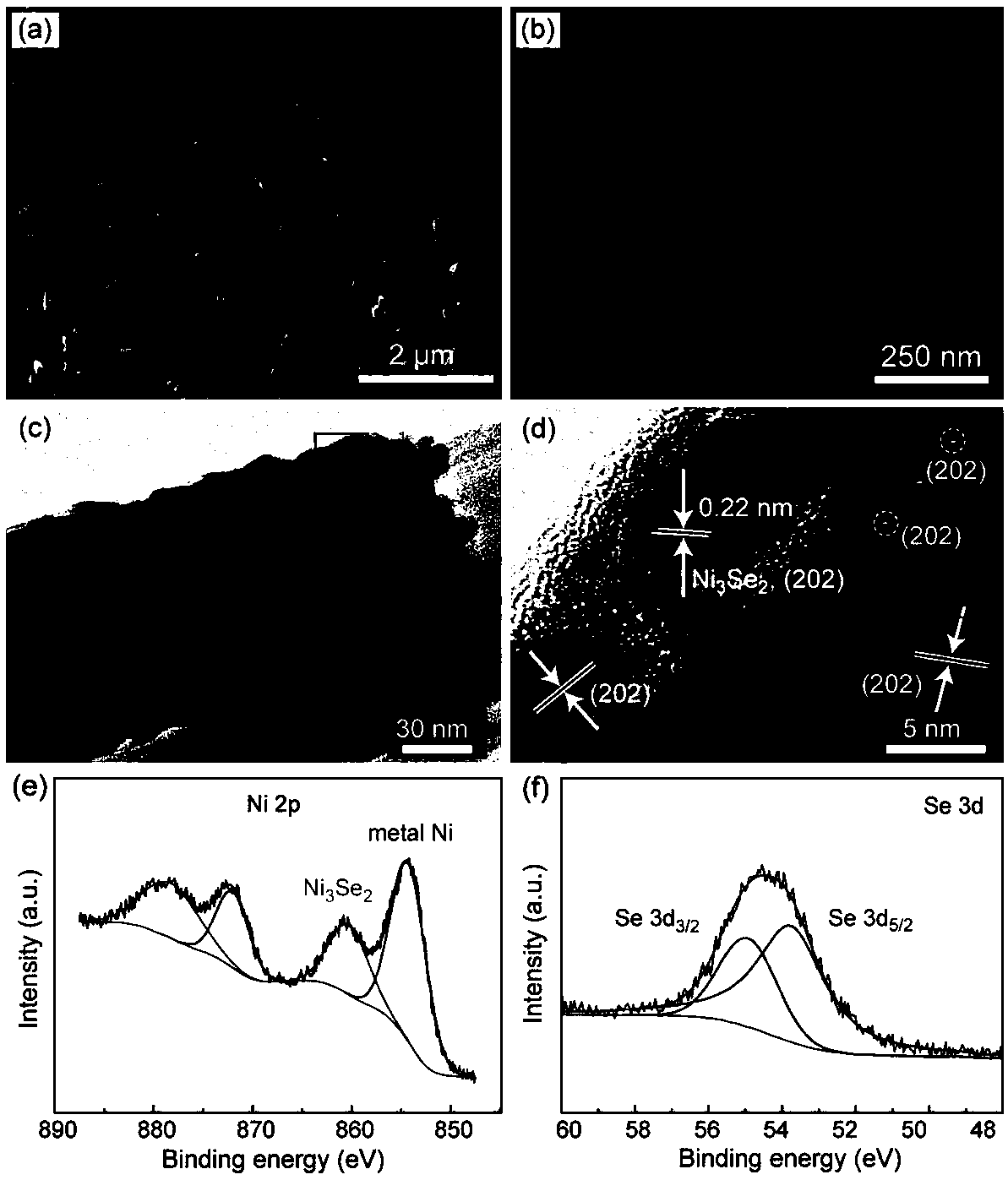

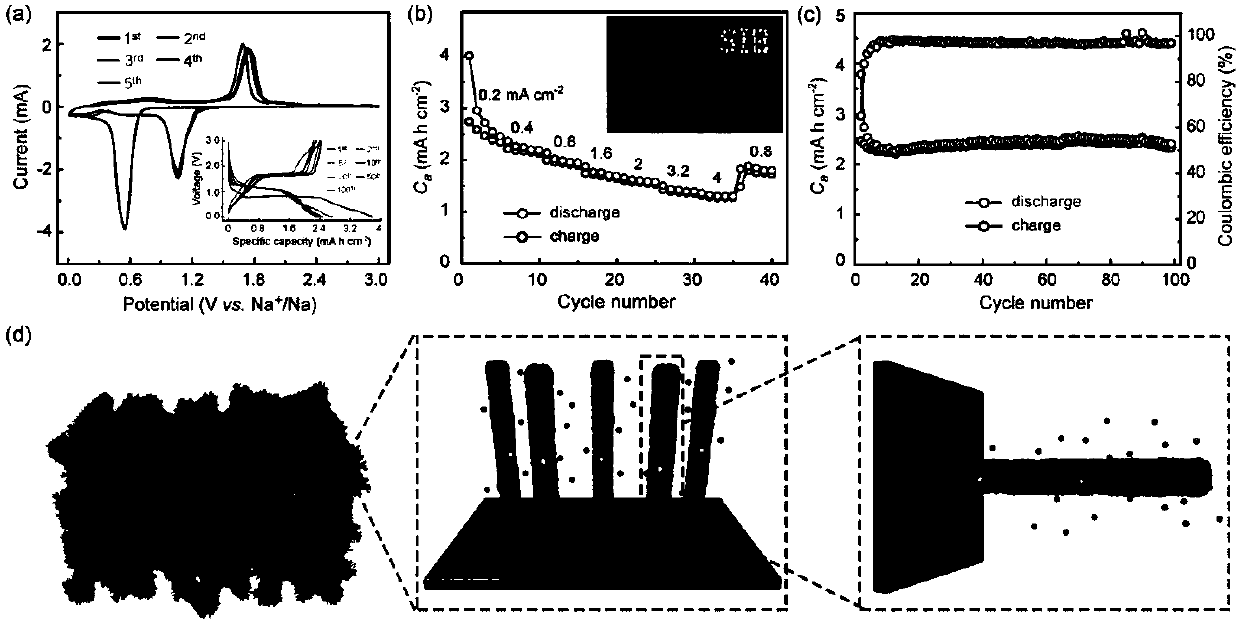

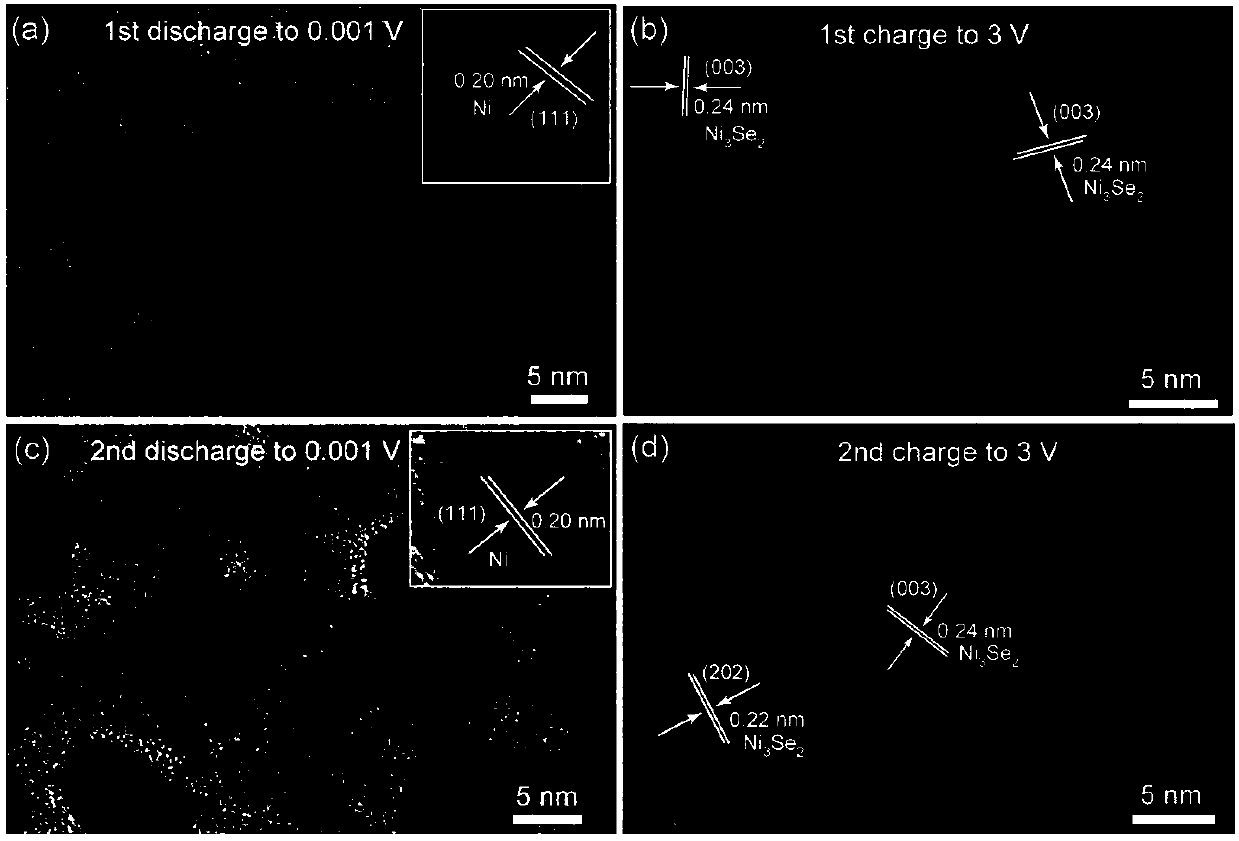

Embodiment 1

[0031] The nickel foam current collector was cut into discs with a diameter of 12mm, then cleaned with hydrochloric acid, ethanol and water, and dried in vacuum for later use. Take the current collector out of the oven, weigh the mass, and take a piece with the same mass for subsequent reactions. Add 20mg of CTAB surfactant to 15mL of hydrazine hydrate solvent and stir, then add 17.6mg of Se powder, continue stirring and dissolving for about 5h, transfer the solution to a 50mL reactor, and then put the current collector sheet of the same quality into the solution. Heat the reaction at 150°C for 12 hours. After the reaction is over, take out the current collector sheet, wash it with water and ethanol, and dry it in vacuum to obtain the initial electrode sheet. Finally, put the electrode sheet into a tube furnace at 600°C under the protection of an inert atmosphere. After high temperature treatment for 2 hours, the electrode structure was further optimized to obtain the final ne...

Embodiment 2

[0033]The nickel foam current collector was cut into discs with a diameter of 12mm, then cleaned with hydrochloric acid, ethanol and water, and dried in vacuum for later use. Take the current collector out of the oven, weigh the mass, and take a piece with the same mass for subsequent reactions. Add 20mg of CTAB surfactant to 15mL of mixed solvent of hydrazine hydrate and ethanol and stir, then add 17.6mg of Se powder, continue to stir and dissolve for about 5h, transfer the solution to a 50mL reaction kettle, and then put the current collector sheet of the same quality into In the solution, heat the reaction at 150°C for 12 hours. After the reaction, the current collector sheet is taken out, washed with water and ethanol, and dried in vacuum to obtain the initial electrode sheet. Finally, the electrode sheet is placed in a tube furnace and placed in an inert atmosphere Under protection, high temperature treatment at 600°C for 2 hours was carried out to further optimize the el...

Embodiment 3

[0035] The nickel foam current collector was cut into discs with a diameter of 12mm, then cleaned with hydrochloric acid, ethanol and water, and dried in vacuum for later use. Take the current collector out of the oven, weigh the mass, and take a piece with the same mass for subsequent reactions. Add 20mg of CTAB surfactant to 15mL of hydrazine hydrate solvent and stir, then add 17.6mg of Se powder, continue stirring and dissolving for about 5h, transfer the solution to a 50mL reactor, and then put the current collector sheet of the same quality into the solution. Heat the reaction at 150°C for 12 hours. After the reaction is over, take out the current collector sheet, wash it with water and ethanol, and dry it in vacuum to obtain the initial electrode sheet. Finally, put the electrode sheet into a tube furnace at 500°C under the protection of an inert atmosphere. After high temperature treatment for 2 hours, the final negative electrode of sodium ion battery was obtained. Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com