A method for high-value recovery and utilization of molasses alcohol waste liquid

A high-value technology of molasses alcohol waste liquid, which is applied in the field of recycling and utilization of molasses alcohol waste liquid, can solve the problems of waste of resources, high cost of molasses fermentation waste liquid, etc., and achieve the effects of reducing waste water discharge, easy storage, and easy delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

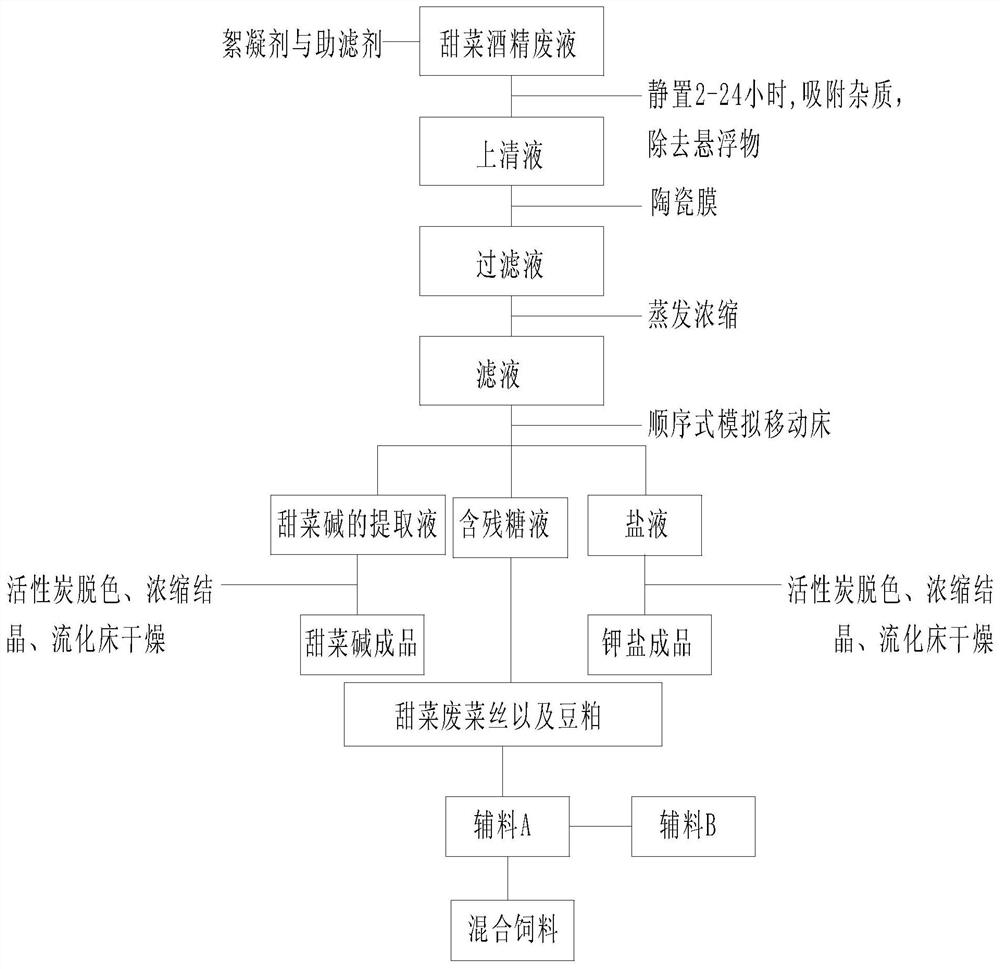

Method used

Image

Examples

Embodiment 2

[0035] (1) Add flocculant polyacrylamide and filter aid to the beet alcohol waste liquid, put the beet alcohol waste liquid at a temperature of 30°C for 2 hours, make the suspension flocculate and settle, and take the supernatant; the flocculant The add-on is: every ton of beet alcohol waste liquid adds 5g flocculant; Described filter aid is made up of the calcium oxide that volume percentage is 40% and the phosphoric acid of 60% by volume percentage; The add-on of described filter aid is: Add 70g filter aid to every ton of sugar beet alcohol waste liquid;

[0036] The supernatant obtained in step (1) passes through a ceramic membrane with a pore size of 0.05-0.1 μm, the operating pressure of the microfiltration process is set to 0.2Mpa, and the operating temperature is set to 40°C; remove bacterial protein and other particulate impurities in the waste liquid, Obtain the filtrate; the above-mentioned filtrate is concentrated to a solid content of 40% by a four-effect evaporato...

Embodiment 3

[0043] (1) Add flocculant polyacrylamide and filter aid to the beet alcohol waste liquid, put the beet alcohol waste liquid at a temperature of 80° C. for 18 hours, make the suspension flocculate and settle, and take the supernatant; the flocculant The add-on is: every ton of beet alcohol waste liquid adds 10g flocculant; Described filter aid is made up of the calcium oxide that is 20% by volume percentage and the phosphoric acid of 80% by volume percentage; The add-on of described filter aid is: Add 90g filter aid to every ton of sugar beet alcohol waste liquid;

[0044] The supernatant obtained in step (1) passes through a ceramic membrane with a pore size of 0.05-0.1 μm, the operating pressure of the microfiltration process is set to 0.3Mpa, and the operating temperature is set to 70°C; remove bacterial protein and other particulate impurities in the waste liquid, Obtain the filtrate; the above-mentioned filtrate is concentrated by a four-effect evaporator to a solid conten...

Embodiment 4

[0051] (1) Add flocculant polyacrylamide and filter aid to the beet alcohol waste liquid, put the beet alcohol waste liquid at a temperature of 100°C for 24 hours to flocculate and settle the suspended matter, and take the supernatant; the flocculant The add-on is: every ton of sugar beet alcohol waste liquid adds 20g flocculant; Described filter aid is made up of the calcium oxide that volume percentage is 10% and the phosphoric acid of 90% by volume percentage; The add-on of described filter aid is: Add 150g filter aid to every ton of sugar beet alcohol waste liquid;

[0052] The supernatant obtained in step (1) passes through a ceramic membrane with a pore size of 0.05-0.1 μm, the operating pressure of the microfiltration process is set to 0.3 MPa, and the operating temperature is set to 40° C.; remove bacterial protein and other particulate impurities in the waste liquid, Obtain the filtrate; the above-mentioned filtrate is concentrated by a four-effect evaporator to a sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cross-linking degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com