Disk tube type nanofiltration membrane and preparation process thereof

A preparation process and nanofiltration membrane technology, which is applied in the field of membrane separation, can solve the problems that nanofiltration membranes cannot be applied to disk-type reverse osmosis membrane systems, and achieve good filtration performance, high desalination rate, and improved membrane performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

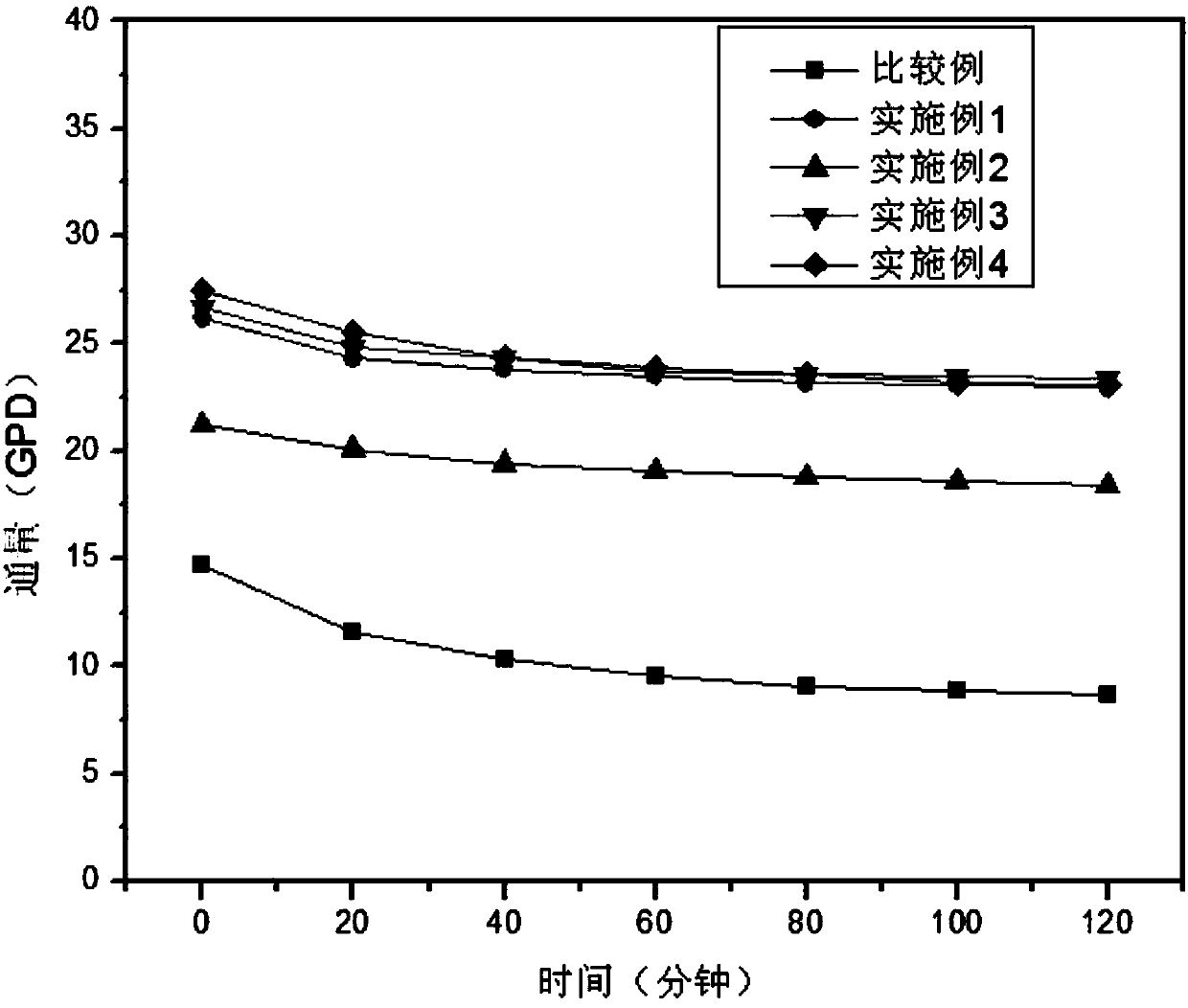

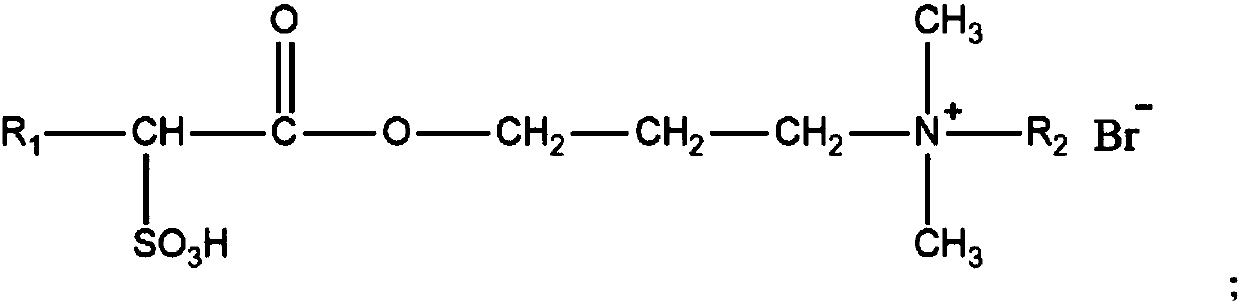

[0027] This embodiment provides a disc-tube nanofiltration membrane, which includes a polyethersulfone base film layer and a modified separation layer arranged on the surface of the base film layer, the modified separation layer is composed of nano-oxide, amphoteric gemini surface Active agent and polypiperazine amide, the mass ratio of described nano-oxide, amphoteric gemini surfactant and polypiperazine amide is 1:1:100, and in the present embodiment, described nano-oxide is nano titanium dioxide, and its Particle diameter is 80nm, and the general structural formula of described amphoteric gemini surfactant is:

[0028]

[0029] Wherein, R1 and R2 are saturated hydrocarbon groups, and in this embodiment, the R1 is CH 3 (CH 2 ) 2 -, the R2 is CH 2 CH 3 -, the molecular formula of the amphoteric gemini surfactant is: CH 3 (CH 2 ) 2 CHSO 3 HCOO (CH 2 ) 3 NBr(CH 3 ) 2 CH 2 CH 3 .

[0030] The present embodiment also provides a kind of technique for preparing de...

Embodiment 2

[0036] This embodiment provides a disc-tube nanofiltration membrane, which includes a polyethersulfone base film layer and a modified separation layer arranged on the surface of the base film layer, the modified separation layer is composed of nano-oxide, amphoteric gemini surface Active agent and polypiperazine amide composition, the mass ratio of described nano-oxide, amphoteric gemini surfactant and polypiperazine amide is 100:200:400, and in the present embodiment, described nano-oxide is nano silicon dioxide , its particle diameter is 100nm, and the general structural formula of described amphoteric gemini surfactant is:

[0037]

[0038] Wherein, R1 and R2 are saturated hydrocarbon groups, and in this embodiment, the R1 is CH 3 -, the R2 is CH 3 CH 2 CH 2 -, the molecular formula of the amphoteric gemini surfactant is: CH 3 CHSO 3 HCOO (CH 2 ) 3 NBr(CH 3 ) 2 (CH 2 ) 2 CH 3 .

[0039] The present embodiment also provides a kind of technique for preparing d...

Embodiment 3

[0045] This embodiment provides a disc-tube nanofiltration membrane, which includes a polyethersulfone base film layer and a modified separation layer arranged on the surface of the base film layer, the modified separation layer is composed of nano-oxide, amphoteric gemini surface Active agent and polypiperazine amide composition, the mass ratio of described nano-oxide, amphoteric gemini surfactant and polypiperazine amide is 25:60:250, and in the present embodiment, described nano-oxide is nano graphene oxide , its particle diameter is 60nm, and the structural general formula of described amphoteric gemini surfactant is:

[0046]

[0047] Wherein, R1 and R2 are saturated hydrocarbon groups, and in this embodiment, the R1 is CH 3 -, the R2 is CH 3 -, the molecular formula of the amphoteric gemini surfactant is: CH 3 CHSO 3 HCOO (CH 2 ) 3 NBr(CH 3 ) 2 CH 3 .

[0048] The present embodiment also provides a kind of technique for preparing described disc-tube nanofiltr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com