A kind of preparation method of modified ionic liquid catalyst for removing sulfur dioxide

A technology for modifying ions and sulfur dioxide, applied in physical/chemical process catalysts, separation methods, chemical instruments and methods, etc., can solve problems such as precipitation of sulfur, sulfur process methods that have not been reported or have not been solved, and can achieve increased The effect of absorption, promotion of gas-liquid mass transfer ability, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Embodiment 1: A kind of preparation method of the modified ionic liquid catalyst that is used to remove sulfur dioxide, concrete steps are:

[0038] (1) Add citric acid to deionized water under stirring conditions at a temperature of 60°C to prepare a citric acid solution, wherein the mass concentration of citric acid in the citric acid solution is 40%;

[0039] (2) At a temperature of 80°C, add alcohol amine to the citric acid solution obtained in step (1) and stir evenly to obtain ionic liquid A, wherein the mass ratio of alcohol amine to citric acid is 1.5:1;

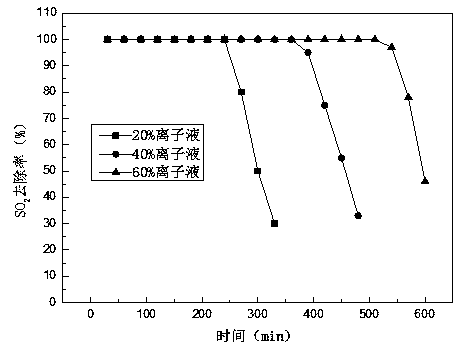

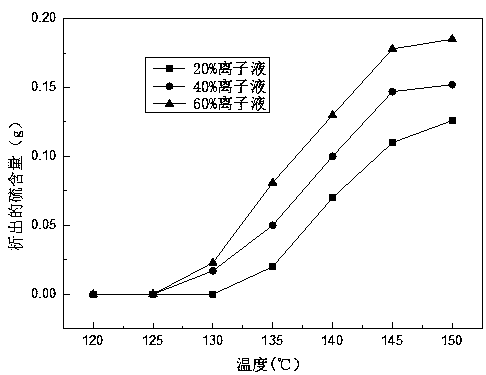

[0040] (3) Under the condition of stirring at a temperature of 60°C and a rotation speed of 500r / min, take three parts of the same mass of step (2) Ionic liquid A in different beakers, add water to dilute to obtain ionic liquid B, and the amount of water in ionic liquid B is The mass fractions are 40%, 60%, and 80%, that is, the cation contents in the ionic liquid are 60%, 40%, and 20%, respectively. ;

[004...

Embodiment 2

[0042] Embodiment 2: A kind of preparation method of the modified ionic liquid catalyst that is used to remove sulfur dioxide, concrete steps are:

[0043] (1) Add citric acid to deionized water under stirring conditions at a temperature of 60°C to prepare a citric acid solution, wherein the mass concentration of citric acid in the citric acid solution is 40%;

[0044] (2) At a temperature of 80°C, add alcohol amine to the citric acid solution obtained in step (1) and stir evenly to obtain ionic liquid A, wherein the mass ratio of alcohol amine to citric acid is 1.5:1;

[0045] (3) Under the condition of stirring at a temperature of 40°C, add water to dilute the ionic liquid A in step (2) to obtain an ionic liquid B, wherein the mass fraction of water in the ionic liquid B is 40%;

[0046] (4) Under stirring conditions, add ammonia water dropwise to the ionic liquid B obtained in step (3) to adjust the pH value of the ionic liquid to 7.5;

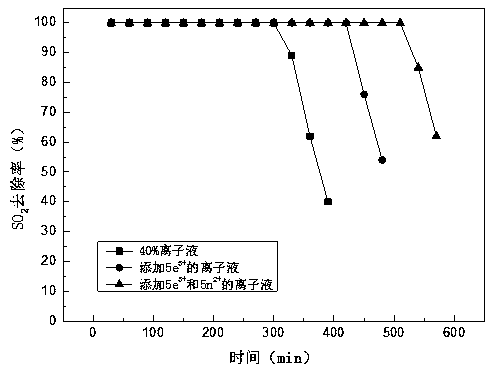

[0047] (5) Add iron salt (iron salt...

Embodiment 3

[0050] Embodiment 3: a kind of preparation method for the modified ionic liquid catalyst of removing sulfur dioxide, concrete steps are:

[0051] (1) Add citric acid to deionized water under stirring conditions at a temperature of 80°C to prepare a citric acid solution, wherein the mass concentration of citric acid in the citric acid solution is 40%;

[0052] (2) At a temperature of 40°C, add alcohol amine to the citric acid solution obtained in step (1) and stir evenly to obtain ionic liquid A, wherein the mass ratio of alcohol amine to citric acid is 2:1;

[0053] (3) Under the condition of stirring at a temperature of 60°C, add water to dilute the ionic liquid A in step (2) to obtain an ionic liquid B, wherein the mass fraction of water in the ionic liquid B is 60%;

[0054] (4) Under stirring conditions, take three parts of the same volume of ionic liquid B obtained in step (3) in three beakers, and add ammonia water drop by drop to adjust the pH value of the ionic liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com