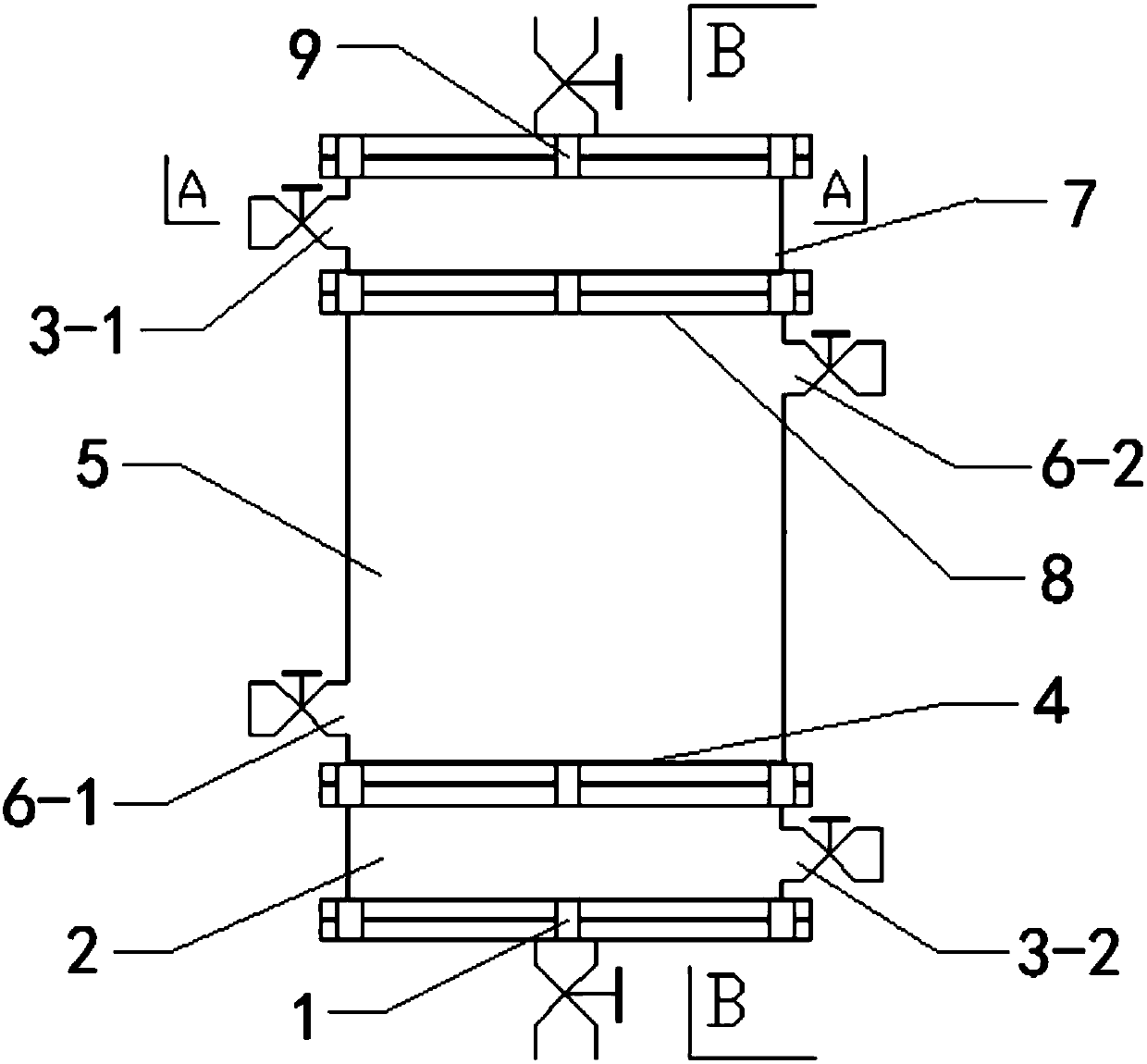

Advanced oxidation reactor for activating PS (persulfate) based on MOFs (Metal organic Framework) and method for treating wastewater by using reactor

A reactor and reaction technology, which is applied in chemical instruments and methods, oxidized water/sewage treatment, special treatment targets, etc., can solve the problems that ferrous ions cannot be recycled, the particle size of MOFs materials is small, and the utilization rate of space resources is insufficient. , to achieve the effect of saving raw materials and energy, facilitating the distribution and pressure drop of water flow, and saving the amount of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

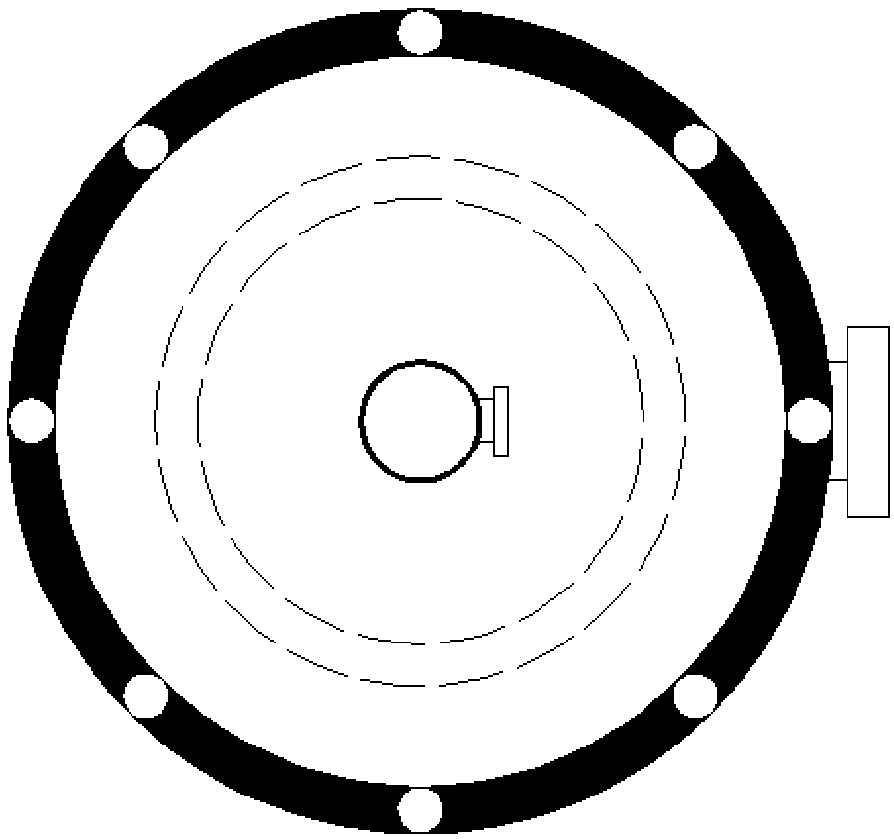

Method used

Image

Examples

Embodiment 1

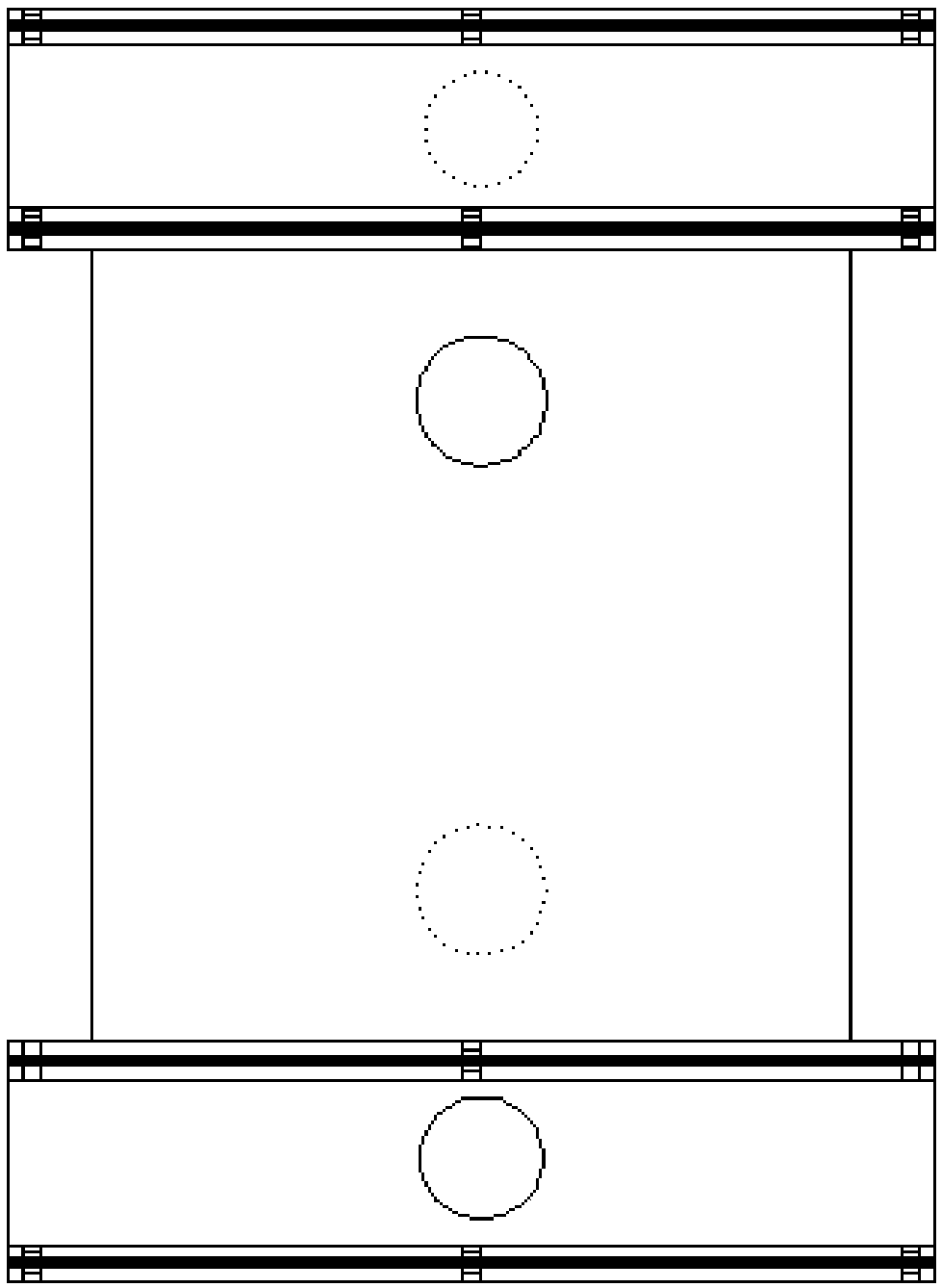

[0061] The method for treating waste water using a reactor based on MOFs activated PS, wherein, in the reactor based on MOFs activated PS, the sieve plate on the bottom surface of the MOFs material filling layer has a pore size of 2-3mm and a porosity of 80%. , the specific processing includes the following steps:

[0062] (1) Utilize OG (orange yellow G) to prepare printing and dyeing simulated wastewater, the OG simulated wastewater concentration is 0.2mM, and the preparation concentration is a sodium persulfate (PS) solution of 2mM, and the influent ratio is mixed according to the mass ratio PS:12OG=1.5:1 ( The flow of waste water and sodium persulfate solution is monitored by flowmeter), that is, the PS water inlet valve and the OG water inlet valve are controlled, and the flow rate is adjusted to ensure water inflow in proportion. The MOFs material filling volume is based on the ratio of the MOFs material filling layer cavity volume Add the prepared MOFs material (MIL-100...

Embodiment 2

[0070] The method for treating waste water using a reactor based on MOFs activated PS, wherein, in the reactor based on MOFs activated PS, the sieve plate on the bottom surface of the MOFs material filling layer has a pore size of 2-3mm and a porosity of 85%. , the specific processing includes the following steps:

[0071](1) The waste water from a paper mill in Dongguan after biochemical treatment was used for water leakage experiments. The initial COD concentration of the papermaking wastewater was 140mg / L, and after biochemical treatment, it still contained some refractory organic pollutants such as benzene rings. Sodium sulfate solution, according to the mass ratio PS: 12CODcr = 1:1, control the water flow and mix in proportion (the flow of waste water and sodium persulfate solution is monitored by flowmeter), and pump it into the three-stage packing column from bottom to top through the water inlet pump Type reactor, MOFs material filling amount is 2g / L according to the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com