Cubic boron nitride complex, and preparation method and application thereof

A technology of cubic boron nitride and composites, applied in the field of materials, can solve problems such as the decrease in the bonding strength of abrasives and substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0231] The present invention also provides a method for preparing the cubic boron nitride complex, comprising the steps of:

[0232] 1) A mixture is provided, the mixture comprises a cubic boron nitride primary complex, an anti-oxidation coating raw material and an optional solvent, the cubic boron nitride primary complex comprises cubic boron nitride and is coated on the The active material coating on the outer surface of the cubic boron nitride;

[0233] 2) heat treating the mixture to obtain the cubic boron nitride complex.

[0234] In another preferred example, the solvent includes (but is not limited to): an organic solvent, water, or a combination thereof.

[0235] In another preferred example, the organic solvent includes (but not limited to): ethanol, acetone, or a combination thereof.

[0236] In another preferred example, the anti-oxidation coating raw materials include (but are not limited to): boron powder, boron-based alloy powder, or a combination thereof.

[...

Embodiment 1

[0311] Example 1 Preparation of Cubic Boron Nitride Primary Composite 1 Surface Plated with Titanium-Based Active Material Coating

[0312] Mix cubic boron nitride with a particle size of about 100 μm, crystalline sodium chloride, and powdered high-purity titanium-aluminum mixed powder (60wt% titanium content) in a mass ratio of 3:1:1. The mixing process Add a small amount of absolute ethanol to mix well. The resulting mixture is put into a salt bath furnace and evacuated to a vacuum degree of about 10 -2 Pascal, then filled with nitrogen, the gas pressure is 1Pa-120kPa, heated to 900°C at a heating rate of 5°C / min and kept for 30min, cooled to room temperature with the furnace, washed with water, and dried to obtain the initial complex 1.

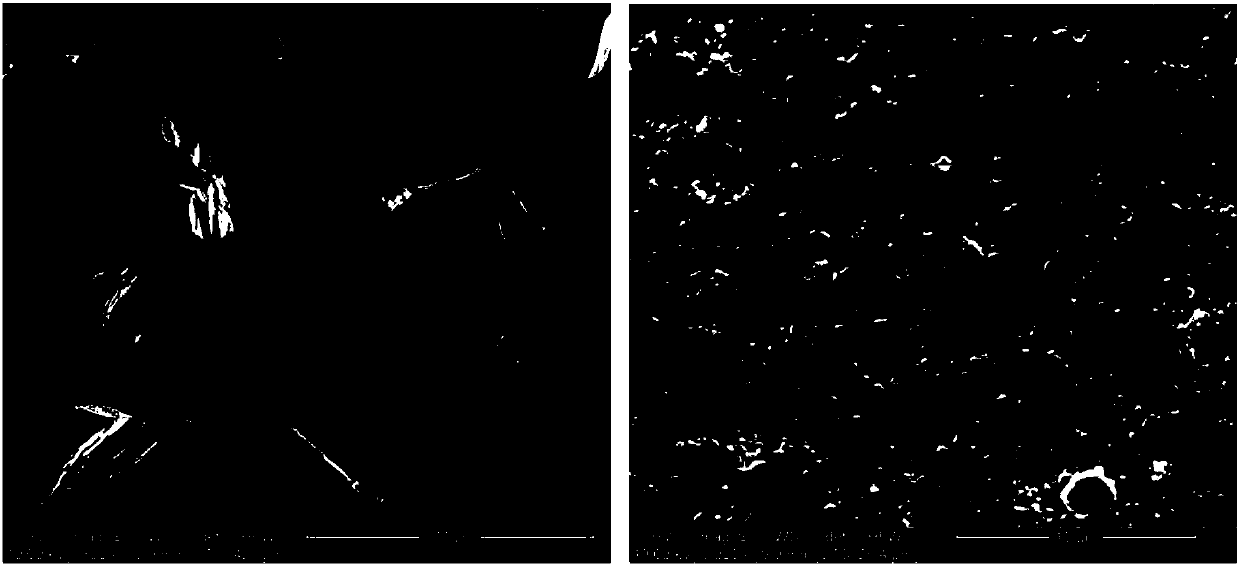

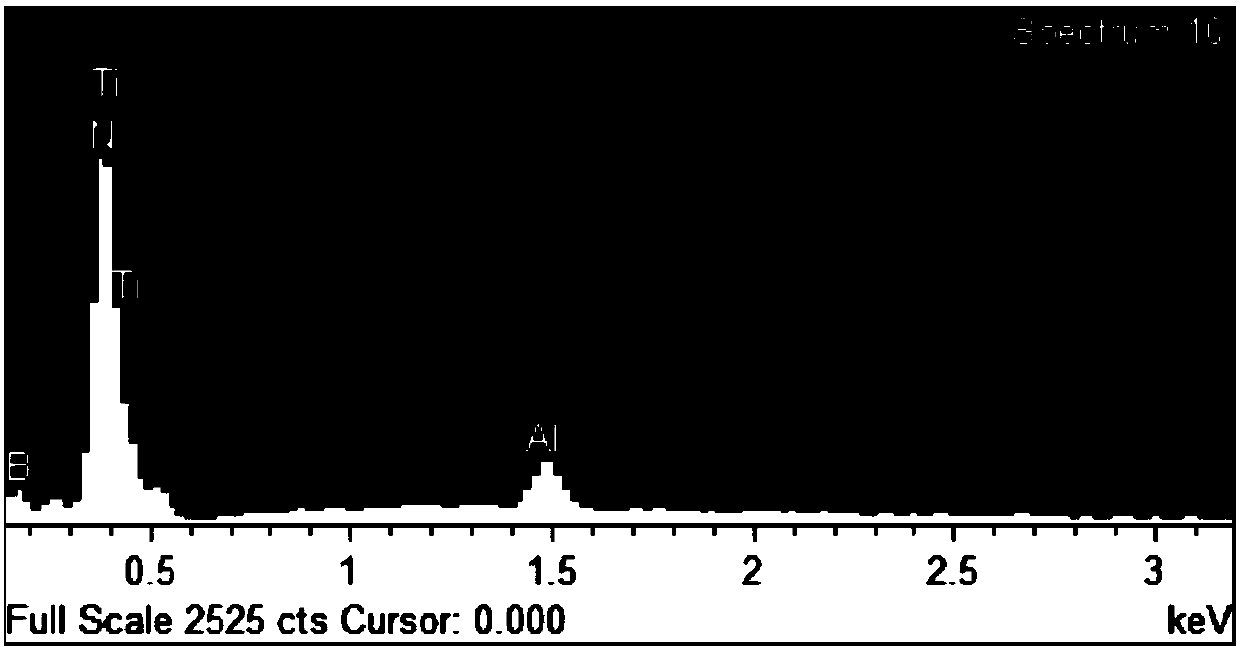

[0313] result

[0314] SEM, EDS and other tests were carried out on the initial composite 1 prepared in Example 1.

[0315] figure 1 It is the SEM image of the initial composite 1 obtained in Example 1 of the present invention.

[031...

Embodiment 2

[0319] Example 2 Preparation of Cubic Boron Nitride Composite 1 Containing Titanium-Based Coating and Boron-Based Coating on the Surface

[0320] The average particle size obtained in Example 1 is 100 μm, the cubic boron nitride primary composite 1 (cBN) (the plating method is salt bath plating) and powdery amorphous high-purity boron coated with a titanium-based aluminum-containing coating on the surface The mass ratio is 5:1 and mixed evenly. The resulting mixture is put into a heating furnace and evacuated to a vacuum degree of about 10 -2 Pascal, and then heated to 900°C at a heating rate of 5°C / min and kept for 60 minutes, cooled to room temperature with the furnace, washed with water, and dried to obtain complex 1.

[0321] result

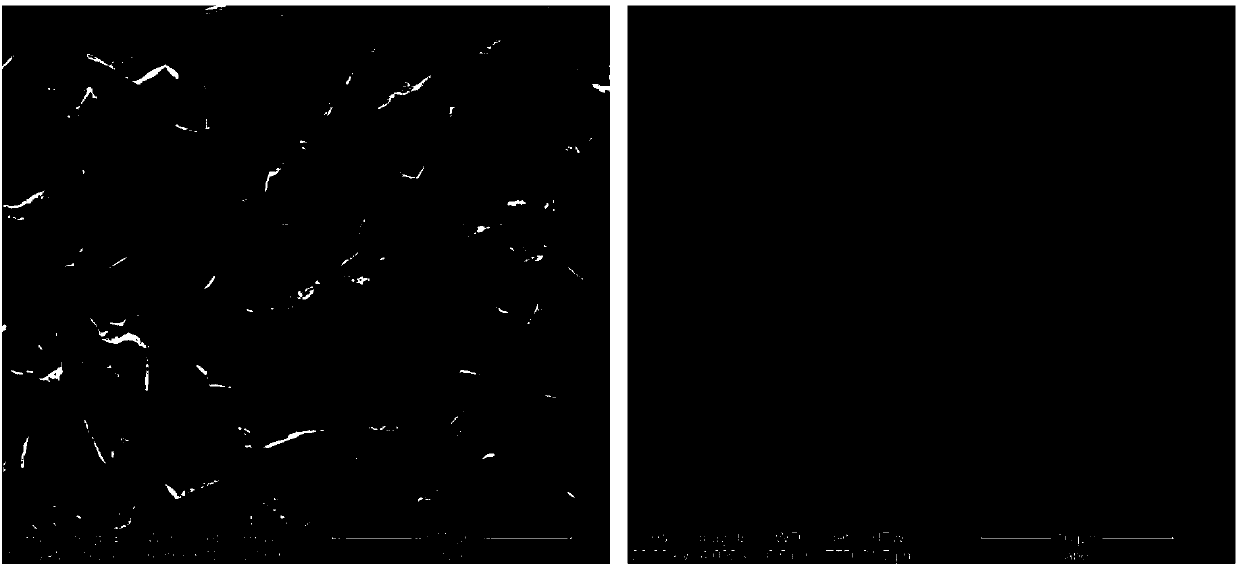

[0322] Performance tests such as SEM and EDS were performed on the complex 1 obtained in Example 2.

[0323] image 3 It is the SEM test result of the complex 1 obtained in Example 2.

[0324] from image 3 It can be seen that the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com