Preparation method of superfine high-diffusion silver-tungsten electric contact material

An electrical contact material, silver-tungsten technology, which is applied in the field of preparation of ultra-fine and high-dispersion silver-tungsten electrical contact materials, can solve the problem of large internal pore size, does not involve the preparation method of ultra-fine and high-dispersion silver-tungsten electrical contact materials, and cannot obtain ultra-fine Dispersed structure and other problems, to achieve the effect of reducing melting, high and reliable arc burnout performance, and improving contact conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

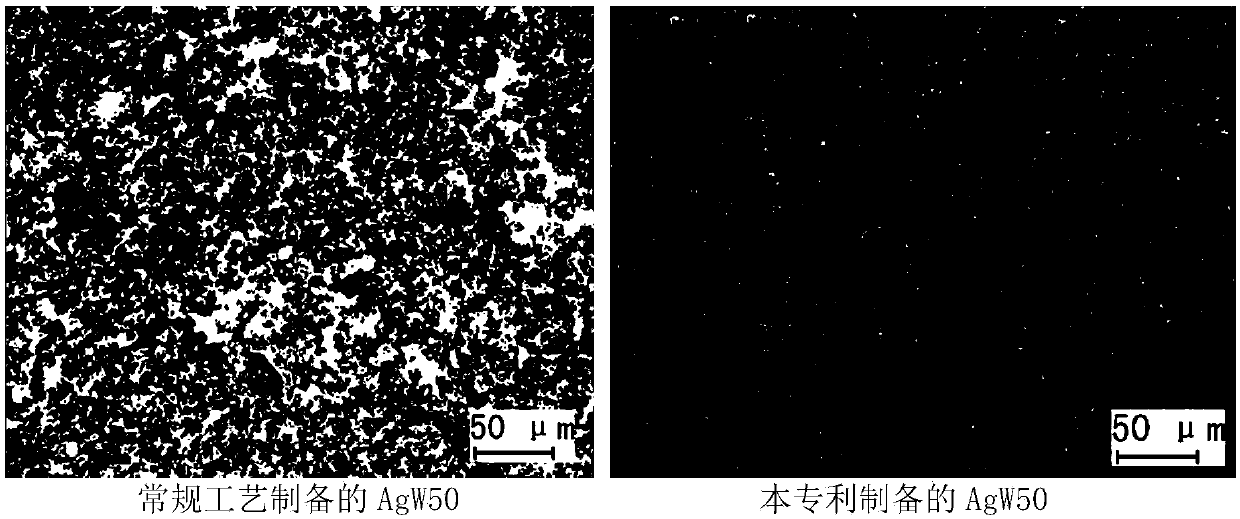

[0024] Taking the preparation of AgW50 material as an example

[0025] 1) Premix spherical tungsten foam powder and activating elements (Be, Ti, Nb) at a ratio of 99.3:0.2:0.3:0.2 for 2 hours; spherical tungsten foam powder has a particle size of 2um, a pore size of 0.1-0.5um, and a porosity of 90 %;

[0026] 2) Mix the premixed powder and silver powder at a ratio of 65:35 for 6 hours to obtain a mixed powder;

[0027] 3) Press the mixed powder into a skeleton with a porosity of 35%;

[0028] 4) The skeleton is exhausted in a vacuum sintering furnace under a vacuum atmosphere of 100Pa at 800°C for 2 hours;

[0029] 5) Put the rest of the weight of the silver sheet on the frame, and infiltrate it in a hydrogen atmosphere at 1300°C for 0.5 hours.

[0030]

Embodiment 2

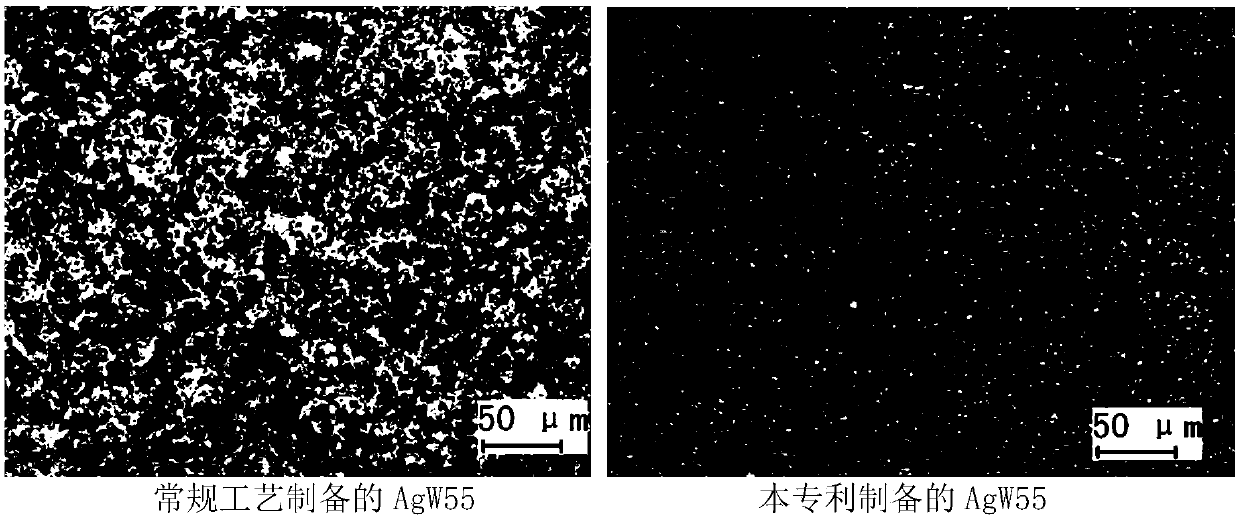

[0032] Taking the preparation of AgW55 material as an example

[0033] 1) Premix spherical tungsten foam powder and activating elements (Ta, Ti, Ni-P) at a ratio of 99.1:0.3:0.5:0.1 for 1 hour; rate 85%;

[0034] 2) Mix the premixed powder and silver powder at a ratio of 70:30 for 7 hours to obtain a mixed powder;

[0035] 3) Press the mixed powder into a skeleton with a porosity of 38%;

[0036] 4) The skeleton is exhausted in a vacuum sintering furnace under a vacuum atmosphere of 80Pa at 750°C for 1.5 hours;

[0037] 5) Put the remaining weight of the silver sheet on the frame, and infiltrate it at 1200° C. for 1 hour in a hydrogen atmosphere.

[0038]

Embodiment 3

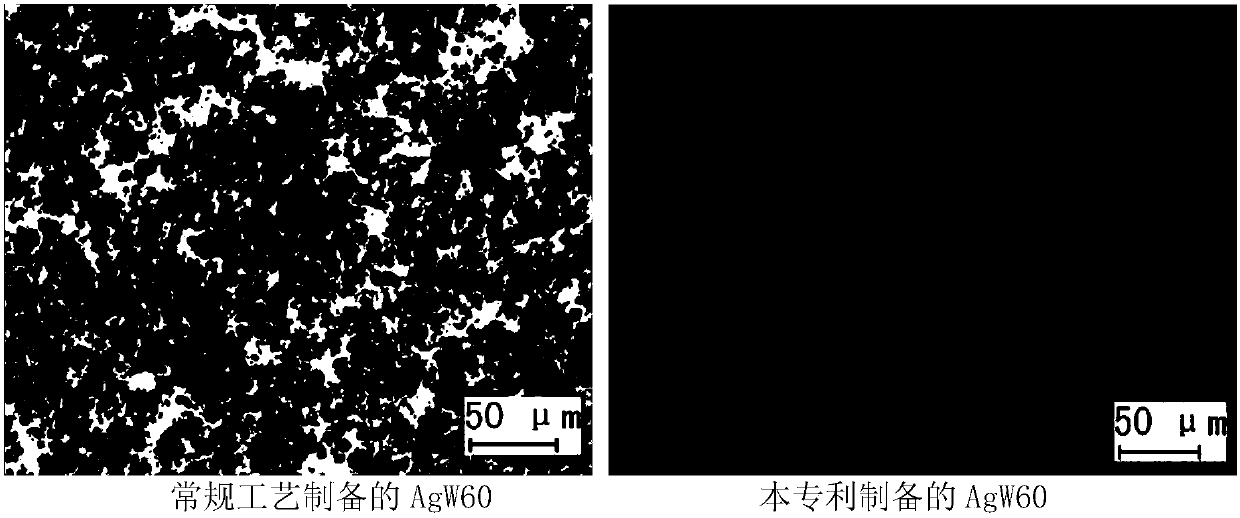

[0040] Taking the preparation of AgW60 material as an example

[0041] 1) Premix spherical tungsten foam powder and activating elements (Al, Li, Nb) at a ratio of 99.5:0.1:0.3:0.1 for 1 hour; spherical tungsten foam powder has a particle size of 3um, a pore size of 0.2-0.6um, and a porosity of 95 %;

[0042] 2) Mix the premixed powder and silver powder at a ratio of 75:25 for 6 hours to obtain a mixed powder;

[0043] 3) Press the mixed powder into a skeleton with 42% porosity;

[0044] 4) The skeleton is degassed in a vacuum sintering furnace under a vacuum atmosphere of 50Pa at 700°C for 4 hours;

[0045] 5) Put the remaining weight of the silver sheet on the frame, and infiltrate it at 1000° C. for 2 hours in a hydrogen atmosphere.

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com