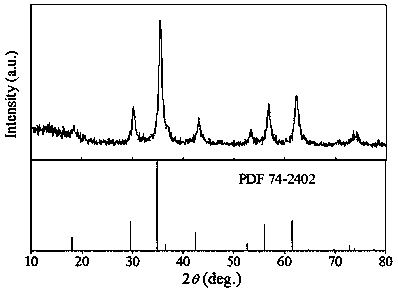

Preparing method of high saturation magnetization strength Mn0.8Zn0.2Fe2O4 nanoparticles and magnetic liquid of nanoparticles

A nanoparticle and magnetization technology, applied in magnetic liquids, magnetic objects, chemical instruments and methods, etc., can solve the problem that the magnetic liquid cannot meet the requirements of high saturation magnetization, and the saturation magnetization of manganese-zinc ferrite nano-magnetic particles is low. and other problems, to achieve the effect of low coercivity, low equipment requirements, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

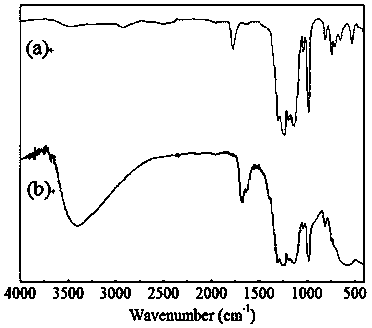

[0023] A high saturation magnetization Mn 0.8 Zn 0.2 Fe 2 o 4 A method for preparing nanoparticles, comprising the following steps:

[0024] A. Weigh MnCl in molar ratio (0.8:0.2:2) 2 4H 2 O, ZnCl 2 , FeCl 3 4H 2 O salt, placed in 500ml of ultrapure water at 85°C, stirred until completely dissolved, and then poured into a reaction kettle with a heat preservation temperature of 85°C. Weigh 25g of NaOH powder, dissolve it in ultrapure water, then quickly add it into the reaction kettle, and at the same time, carry out strong mechanical stirring on the mixed solution, the stirring speed is 800r / min, and the stirring time is 60min.

[0025] B. Put the mixture obtained in A into a high-temperature oven to keep warm at 200°C for 4 hours, and use high temperature to promote the crystallization and growth of particles.

[0026] C. Wash and cool the mixed solution obtained in B to 70°C, and adjust its pH value to 6.23. Add a suitable surfactant, fluether acid, to the mixed sol...

Embodiment 2

[0030] A high saturation magnetization Mn 0.8 Zn 0.2 Fe 2 o 4 A method for preparing nanoparticles, comprising the following steps:

[0031] A. Weigh MnCl in molar ratio (0.8:0.2:2) 2 4H 2 O, ZnCl 2 , FeCl 3 4H 2 O salt, placed in 500ml of ultrapure water at 85°C, stirred until completely dissolved, and then poured into a reaction kettle with a heat preservation temperature of 85°C. Weigh 28g of NaOH powder, dissolve it in ultrapure water, then quickly add it into the reaction kettle, and at the same time, carry out strong mechanical stirring on the mixed solution, the stirring speed is 800r / min, and the stirring time is 60min.

[0032] B. Put the mixture obtained in A into a high-temperature oven to keep warm at 80°C for 4 hours, and use high temperature to promote the crystallization and growth of particles.

[0033] C. Wash and cool the mixture obtained in B to 70°C, and adjust its pH value to 5.1. Add a suitable surfactant, fluether acid, to the mixture in a unifo...

Embodiment 3

[0037] A high saturation magnetization Mn 0.8 Zn 0.2 Fe 2 o 4 A method for preparing nanoparticles, comprising the following steps:

[0038] A. Weigh MnCl in molar ratio (0.8:0.2:2) 2 4H 2 O, ZnCl 2 , FeCl 3 4H 2 O salt, placed in 500ml of ultrapure water at 85°C, stirred until completely dissolved, and then poured into a reaction kettle with a heat preservation temperature of 85°C. Weigh 32g of NaOH powder, dissolve it in ultrapure water, then quickly add it into the reaction kettle, and at the same time vigorously stir the mixed solution with a stirring speed of 800r / min and a stirring time of 60min.

[0039] B. Put the mixture obtained in A into a high-temperature oven to keep warm at 250°C for 3 hours, and use high temperature to promote the crystallization and growth of particles.

[0040] C. Wash and cool the mixture obtained in B to 70°C, and adjust its pH value to 6.96. Add a suitable surfactant, fluether acid, to the mixture in a uniform dropwise manner, with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com