Method for producing soybean isolate protein by high-temperature acid precipitation method

A technology of soybean protein isolate and acid precipitation, which is applied in the field of extraction of soybean protein isolate, can solve the problems of wasting protein resources, protein loss, and increasing the difficulty of sewage treatment, so as to reduce protein content, reduce COD value, and reduce the difficulty of sewage treatment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

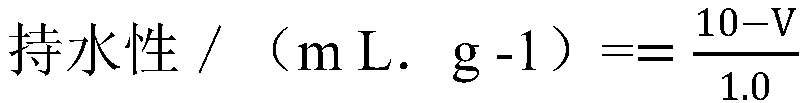

Image

Examples

Embodiment 1

[0051] A method for producing soybean protein isolate by high-temperature acid precipitation, comprising the steps of:

[0052] a) Extraction: mix the raw material low-temperature defatted soybean meal with water at a ratio of 1:8 by weight, add sodium hydroxide to adjust the pH value to 6.8, water temperature 45°C, stir for 15 minutes, use a multi-stage homogeneous pump to pulverize and transport to the storage tank , use microwave sterilization for 5 minutes, store for 30 minutes and wait for separation;

[0053] b) centrifugal separation: centrifuging the extract in step a) to obtain primary bean dregs and primary soymilk, washing the primary bean dregs with water to obtain secondary bean dregs and secondary soymilk, and mixing the primary soymilk and secondary soymilk;

[0054] c) acid precipitation: adjust the pH value of the mixture of primary soybean milk and secondary soybean milk to 4.3, and carry out sedimentation; add 0.2‰ Tween 80 with solid content before sedimentat...

Embodiment 2

[0062] A method for producing soybean protein isolate by high-temperature acid precipitation, comprising the steps of:

[0063] a) Extraction: Mix the raw material low-temperature defatted soybean meal with water at a ratio of 1:10 by weight, add sodium hydroxide to adjust the pH value to 7.5, water temperature 35°C, stir for 15 minutes, use a multi-stage homogeneous pump to pulverize and transport to the storage tank , use microwave sterilization for 2 minutes, store for 30 minutes and wait for separation;

[0064] b) centrifugal separation: centrifuging the extract in step a) to obtain primary bean dregs and primary soymilk, washing the primary bean dregs with water to obtain secondary bean dregs and secondary soymilk, and mixing the primary soymilk and secondary soymilk;

[0065] c) Acid precipitation: adjust the pH value of the mixture of primary soybean milk and secondary soybean milk to 4.8, and carry out sedimentation; add 0.3‰ Tween 80 with solid content before sedimen...

Embodiment 3

[0073] A method for producing soybean protein isolate by high-temperature acid precipitation, comprising the steps of:

[0074] a) Extraction: mix the raw material low-temperature defatted soybean meal with water in a ratio of 1:5 by weight, add sodium hydroxide to adjust the pH value to 7.0, water temperature 40°C, stir for 10 minutes, use a multi-stage homogeneous pump to pulverize and transport to the storage tank , use microwave sterilization for 3 minutes, store for 20 minutes and wait for separation;

[0075] b) centrifugal separation: centrifuging the extract in step a) to obtain primary bean dregs and primary soymilk, washing the primary bean dregs with water to obtain secondary bean dregs and secondary soymilk, and mixing the primary soymilk and secondary soymilk;

[0076] c) Acid precipitation: adjust the pH value of the mixture of primary soybean milk and secondary soybean milk to 4.5, and carry out sedimentation; add 0.1‰ Tween 80 with solid content before sediment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com