Hard-coating film for display device, and display device comprising same

A technology for display devices and hard coatings, applied in coatings, static indicators, instruments, etc., can solve the problems of unsatisfactory continuous folding durability and achieve the effect of improving flexibility, high surface hardness and transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

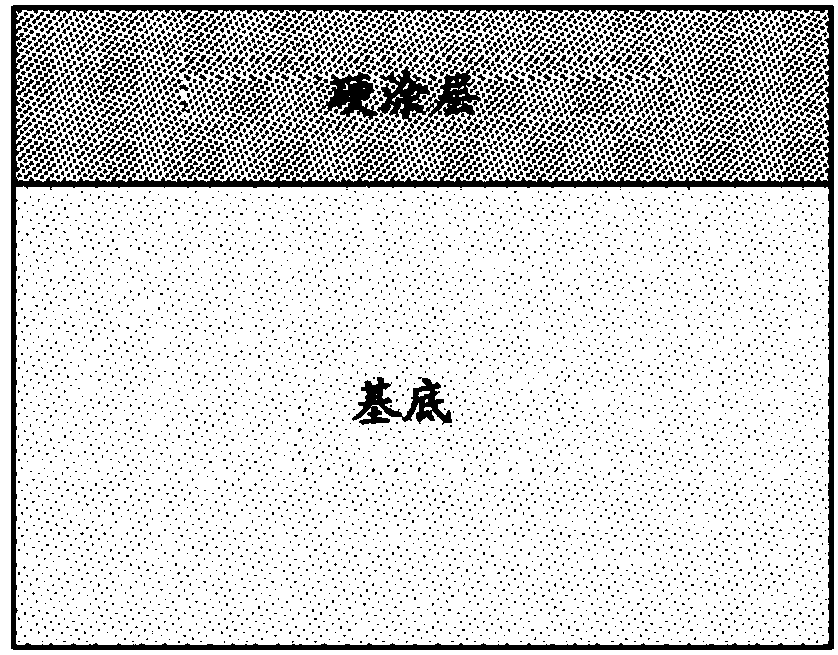

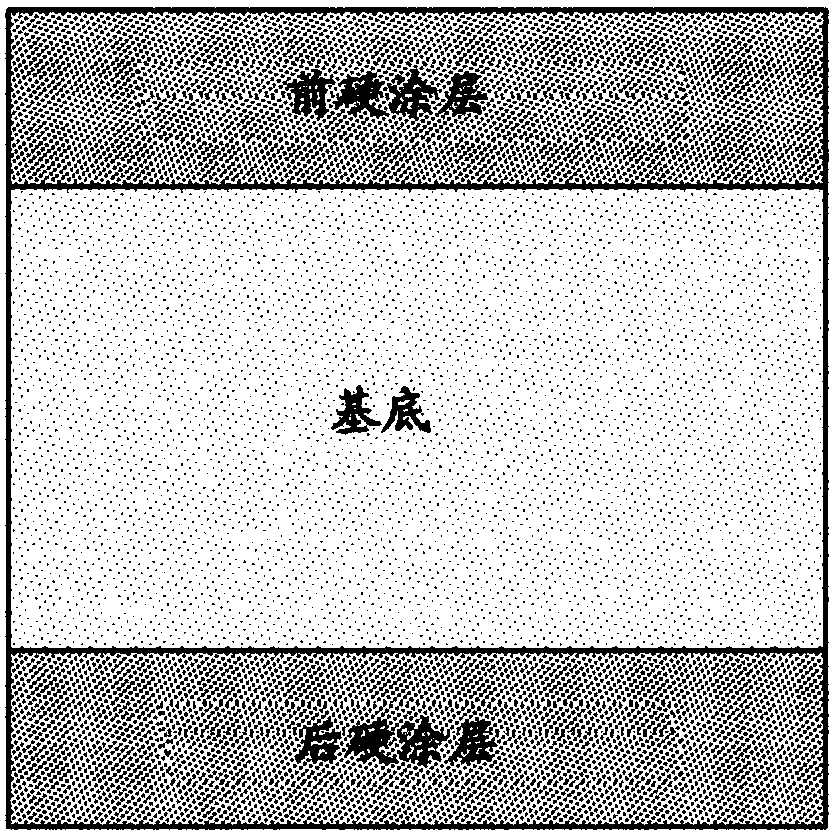

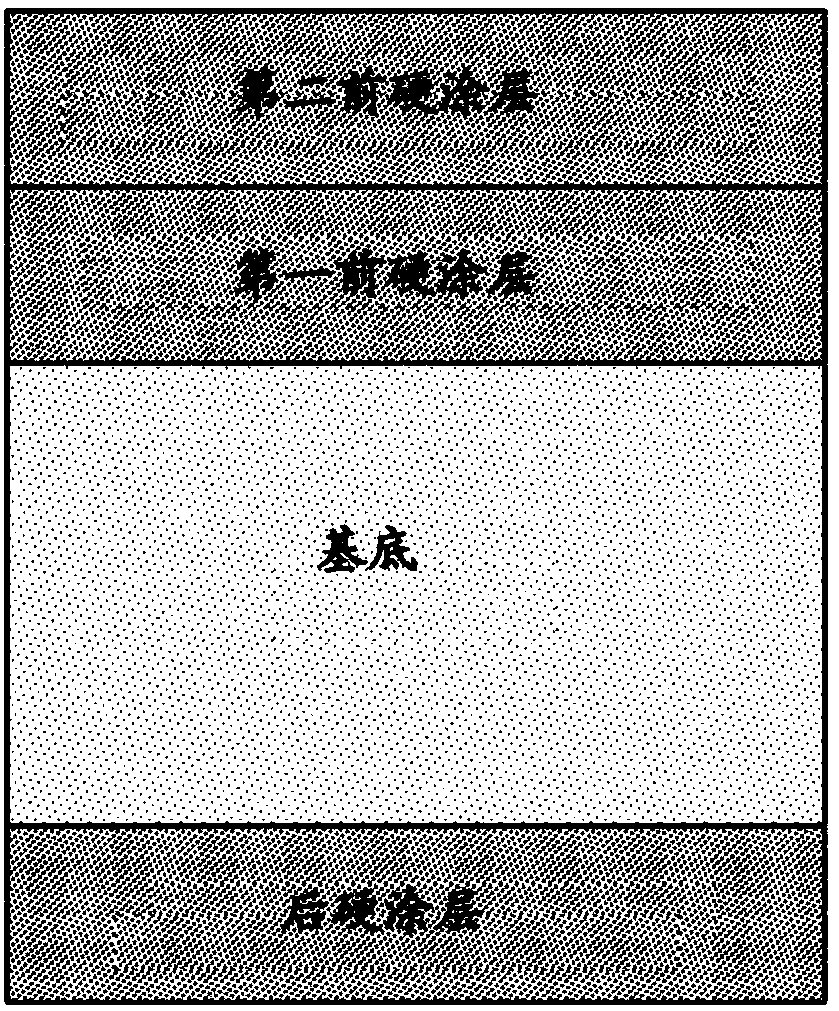

Method used

Image

Examples

Embodiment

[0121] 1. Measurement method

[0122] [1] Thickness measurement

[0123] A micrometer (micrometer) (Mitutoyo Corporation) was used.

[0124] [2] Pencil hardness

[0125] The pencil scratch hardness was measured according to ASTM D3363 using a pencil hardness tester (Automatic Pencil Scratch Hardness Tester No. 553-M1, YASUDA SEIKI SEISAKUSHOL Ltd.) and a Mitsubishi pencil. Specifically, the highest pencil hardness was confirmed when the film was fixed on a glass plate of 2 mm thickness and the pencil was moved back and forth five times at a speed of 60 mm / minute with a vertical weight of 1 kg for 10 mm.

[0126] [3] Yellow Index (YI)

[0127] It is measured using a UV spectrophotometer (Konica Minolta Inc., cm-3600d) according to ASTM E313 standard.

[0128] [4] Modulus

[0129] The modulus was obtained by stretching a film sample of 10 mm width and 50 mm length at room temperature using an Instron 3365 at a speed of 50 cm / min, measuring each sample five times according t...

preparation Embodiment 1

[0137] Preparation Example 1: Manufacture of Polyimide Film

[0138] A polyimide (PI) substrate (50 μm thick) comprising the following condensation / polymerization compounds was prepared as follows: 4,4-(hexafluoroisopropylidene) diphthalic anhydride (6FDA), biphenyl tetra Carboxylic dianhydride (BPDA) and bis(trifluoromethyl)-[1,1-biphenyl]4,4-diamine (TFDB) (molar ratio between diamine and anhydride = about 1:1, 6FDA:BPDA=1:3).

[0139] Fill 700g N,N-dimethylacetamide (DMAc) to the 2L three-neck round bottom flask that is equipped with stirrer, nitrogen inlet, dropping funnel, temperature controller and cooler as reactor, feed nitrogen simultaneously, And cooled to 0° C., then 22.2 g (0.05 mol) of 6FDA, 44.1 g (0.15 mol) of BPDA and 64 g (0.2 mol) of TFDB were dissolved therein. Subsequently, the solution was allowed to stand and stir at room temperature for 24 hours. When the reaction was completed, the polyamic acid solution thus obtained was cast on a glass substrate wi...

preparation Embodiment 2

[0141] Preparation Example 2: Manufacture of Polyimide Film

[0142]A polyimide (PI) substrate (PI-2, 50 μm thick) comprising the following condensation / polymerization compound was prepared according to a method similar to that of Preparation Example 1: 4,4-(hexafluoroisopropylidene) di-orthophenyl Diformic anhydride (6FDA), biphenyltetracarboxylic dianhydride (BPDA), and bis(trifluoromethyl)-[1,1-biphenyl]4,4-diamine (TFDB) (diamine and anhydride The molar ratio of = about 1:1, 6FDA:BPDA=4:1). The substrate had a transmission of 89.8%, a haze of 1.2%, a yellowness index of 1.5, a modulus of 4.2 GPa, and a pencil hardness of B (on glass).

[0143] Synthesis Example 1: Preparation of (meth)acrylate polymer (A1)

[0144] Put 229 parts by mass of methyl isobutyl ketone into a reactor equipped with a stirrer, a cooling tube, a dropping funnel, and a nitrogen inlet valve, and then heat to 110 °C while stirring, and then pass through the dropping funnel to gradually 309 parts by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elasticity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com