Biological fermentation feed for sows and preparation method of biological fermentation feed

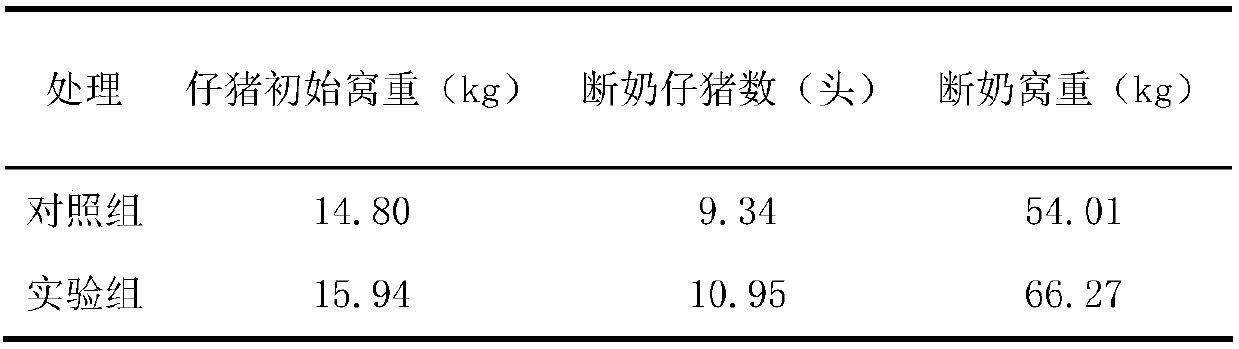

A technology for biologically fermented feed and breeding sows, which is applied to the field of biologically fermented feed for sows and its preparation, can solve the problems of poor palatability, heavy sourness, poor digestibility, etc. Effects of probiotic content and probiotic metabolite content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of sow biofermentation feed preparation, comprises the following steps:

[0024] Step 1: Weigh 400kg of vinegar grains, dry them in a fluidized bed until the moisture content is 8%, then mix them evenly with 200kg of soybean meal, 250kg of bran, and 150kg of corn flour, then mix the mixed vinegar grains, soybean meal, The bran and corn flour are pulverized so that the pass rate of passing through a 60-mesh standard sieve is 100%, and a composite fermentation substrate is obtained;

[0025] Step 2: Take 3×10 9 cfu / ml Bacillus subtilis powder 0.2kg, 2×10 8 cfu / ml Enterococcus faecium powder 0.4kg, 5×10 8 Add 2 kg of cfu / ml Saccharomyces cerevisiae powder into 100 L of warm water at 30°C and stir for 5 minutes to prepare a compound fermentation broth;

[0026] Step 3: inoculating the composite fermentation bacterial liquid obtained in step 2 onto the composite fermentation substrate obtained in step 1 to obtain a biological feed material;

[0027] Step 4: fermen...

Embodiment 2

[0030] A kind of preparation of biological fermented feed for sows, comprises the following steps:

[0031] Step 1: Weigh 500kg of vinegar grains, dry them in a fluidized bed until the moisture content is 10%, then mix them evenly with 300kg of soybean meal, 150kg of bran, and 50kg of corn flour, then mix the mixed vinegar grains, soybean meal, The bran and corn flour are pulverized so that the pass rate of passing through a 60-mesh standard sieve is 100%, and a composite fermentation substrate is obtained;

[0032] Step 2: Take 10 9 cfu / ml Bacillus subtilis powder 1kg, 5×10 8 cfu / ml Enterococcus faecium powder 1kg, 2×10 8 Add 2 kg of cfu / ml Saccharomyces cerevisiae powder into 100 L of warm water at 30°C and stir for 5 minutes to prepare a compound fermentation broth;

[0033] Step 3: inoculating the compound fermentation bacterial liquid obtained in step 2 onto the compound fermentation substrate obtained in step 1 to obtain a biological feed material;

[0034] Step 4: f...

Embodiment 3

[0037] A kind of preparation of biological fermented feed for sows, comprises the following steps:

[0038] Step 1: Weigh 450kg of vinegar grains, dry them in a fluidized bed until the moisture content is 9%, then mix them evenly with 250kg of soybean meal, 200kg of bran, and 100kg of corn flour, then mix the mixed vinegar grains, soybean meal, The bran and corn flour are pulverized so that the pass rate of passing through a 60-mesh standard sieve is 100%, and a composite fermentation substrate is obtained;

[0039] Step 2: Take 2×10 9 cfu / ml Bacillus subtilis powder 0.6kg, 3×10 8 cfu / ml Enterococcus faecium powder 0.7kg, 3×10 8 Add 3.5kg of cfu / ml Saccharomyces cerevisiae powder into 100L of warm water at 30°C and stir for 5 minutes to prepare a compound fermentation broth;

[0040] Step 3: inoculating the compound fermentation bacterial liquid obtained in step 2 onto the compound fermentation substrate obtained in step 1 to obtain a biological feed material;

[0041] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com