Plant capsule shell and preparation method thereof

A plant capsule and carrageenan technology, which is applied in capsule delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problems of long disintegration time of capsule shells and unsuitability for drugs, and achieve good mechanical properties and meet the needs of life. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

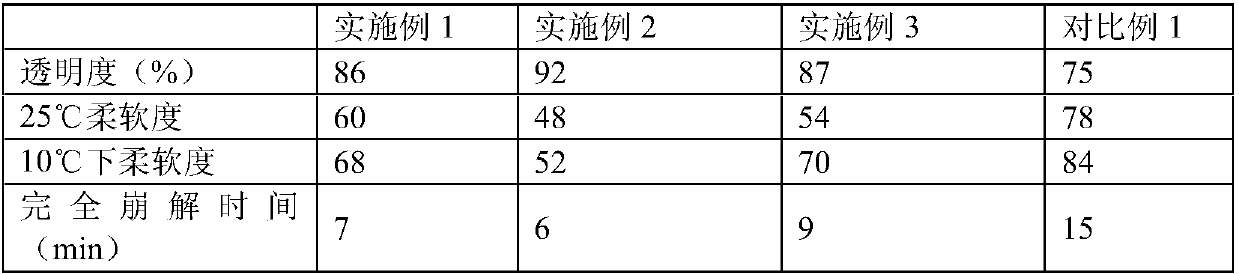

Examples

Embodiment 1

[0022] A vegetable capsule shell, comprising the following components in parts by weight: 18 parts of hydroxypropyl methylcellulose, 0.1 part of K-type carrageenan, 0.2 part of I-type carrageenan, 12 parts of potassium chloride, and 8 parts of magnesium chloride , 2 parts of citronella essential oil, 2 parts of nano titanium dioxide, 12 parts of propylene glycol, 0.1 part of plasticizer, 0.2 part of sorbitol, 12 parts of potassium dihydrogen phosphate, 25 parts of seaweed polysaccharide, 45 parts of purified water. Wherein, the particle size of the nano-titanium dioxide is 10 μm.

[0023] The preparation method of above-mentioned vegetable capsule shell, comprises the following steps:

[0024] Step 1, taking each component by weighing;

[0025] Step 2, add magnesium chloride, potassium chloride, propylene glycol, sorbitol, potassium dihydrogen phosphate, and plasticizer into water, stir to dissolve, then add K-type carrageenan, I-type carrageenan, and seaweed polysaccharide, ...

Embodiment 2

[0029] A vegetable capsule shell, comprising the following components in parts by weight: 20 parts of hydroxypropyl methylcellulose, 2 parts of K-type carrageenan, 6 parts of I-type carrageenan, 15 parts of potassium chloride, and 12 parts of magnesium chloride , 10 parts of citronella essential oil, 5 parts of nano titanium dioxide, 16 parts of propylene glycol, 0.2 parts of plasticizer, 0.4 parts of sorbitol, 13 parts of potassium dihydrogen phosphate, 30 parts of seaweed polysaccharide, 60 parts of purified water. Wherein, the particle size of the nano-titanium dioxide is 10-20 μm.

[0030] The preparation method of above-mentioned vegetable capsule shell, comprises the following steps:

[0031] Step 1, taking each component by weighing;

[0032] Step 2, add magnesium chloride, potassium chloride, propylene glycol, sorbitol, potassium dihydrogen phosphate, and plasticizer into water, stir to dissolve, then add K-type carrageenan, I-type carrageenan, and seaweed polysacchar...

Embodiment 3

[0036] A vegetable capsule shell, comprising the following components in parts by weight: 24 parts of hydroxypropyl methylcellulose, 12 parts of K-type carrageenan, 10 parts of I-type carrageenan, 18 parts of potassium chloride, 8- 18 parts, 17 parts of citronella essential oil, 8 parts of nano titanium dioxide, 18 parts of propylene glycol, 0.5 parts of plasticizer, 0.5 parts of sorbitol, 15 parts of potassium dihydrogen phosphate, 38 parts of seaweed polysaccharide, 64 parts of purified water.

[0037] Wherein, the particle size of the nano-titanium dioxide is 10-20 μm.

[0038] The preparation method of above-mentioned vegetable capsule shell, comprises the following steps:

[0039] Step 1, taking each component by weighing;

[0040] Step 2, add magnesium chloride, potassium chloride, propylene glycol, sorbitol, potassium dihydrogen phosphate, and plasticizer into water, stir to dissolve, then add K-type carrageenan, I-type carrageenan, and seaweed polysaccharide, heat to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com