Method for building biological activity gel film layer on surface of biological material containing alkynyl

A technology of biological activity and biomaterials, applied in the field of tissue engineering, can solve problems such as weak binding force, poor modification effect, desorption, etc., and achieve the effect of mild reaction conditions, wide application range and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) forming a film of polyurethane (Mn=70000) containing alkyne groups on glass, with a mass of about 0.2 g, to obtain a polyurethane film containing alkyne groups;

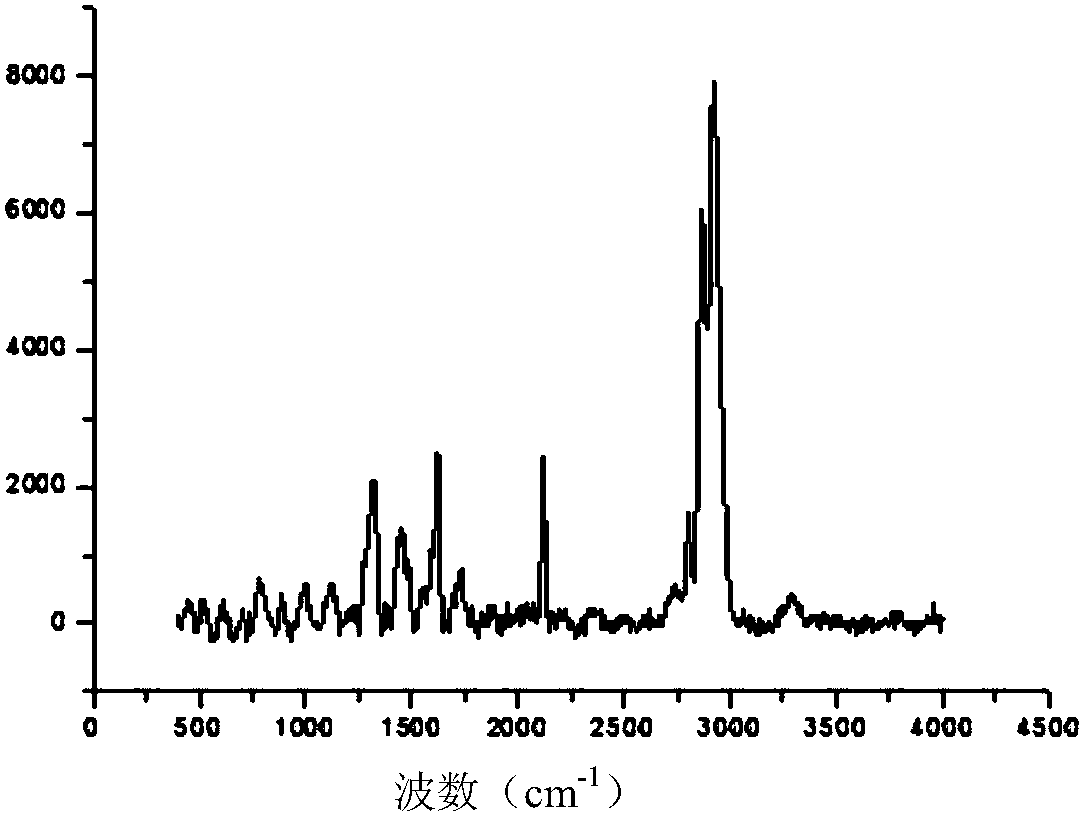

[0038] (2) Add 0.2 g of alkyne-containing polyurethane film (the content of the alkyne group is about 1 mmol / g) (2eq) and 0.5 g of PEG2000 modified with azide groups (the content of the azide group is 0.9 mmol / g) (2eq) into 10ml of water, deoxygenated by nitrogen for 30min; weigh 0.002gCuBr / 0.002gPMDETA (0.01eq / 0.1eq) and dissolve in 0.3ml of anaerobic water to obtain an aqueous solution of the catalyst; add the aqueous solution of the catalyst to the reaction system, under nitrogen protection React at 30°C for 24 hours, take out the polyurethane film from the reaction solution, wash with methanol / water (V / V=1:1) to remove copper ions and unreacted small molecules, dry in vacuum, and compound the PEG gel film layer on the surface of the polyurethane material , to obtain a polyurethane film bonded with a PE...

Embodiment 2

[0049] (1) Electrospinning PAA (Karebay Biochem, Inc, with an alkynyl content of about 1 mmol / g) (Mn=65800) containing alkyne groups (hexafluoroisopropanol as a solvent, and a concentration of 6% in the spinning solution) , the voltage is 12kV, the injection speed is 1ml / h, the pole distance is 10cm), the average pore size is 400μm, and the mass is 1g, and the PAA three-dimensional scaffold containing alkyne groups is obtained;

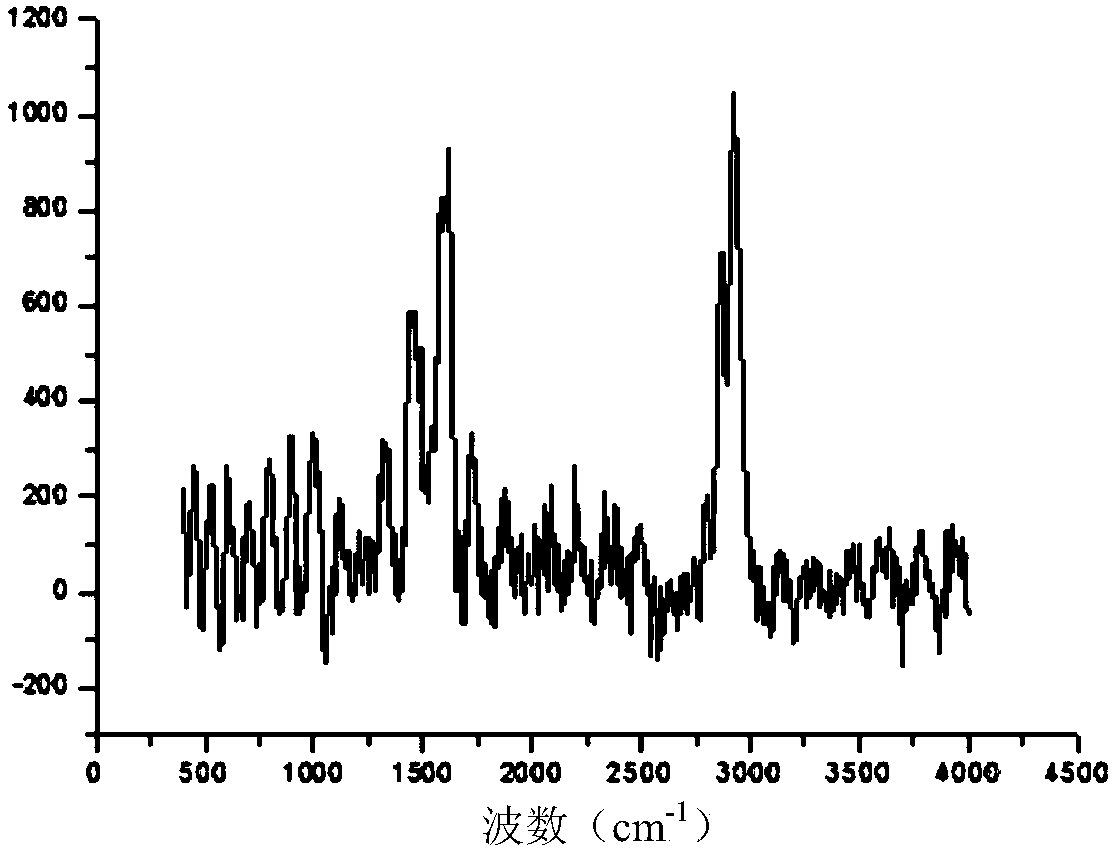

[0050] (2) 1g of PAA three-dimensional scaffold containing alkyne group (alkyne group content is about 1mmol / g) (1eq) and 1g chitosan modified with azido group (azido group content 2mmol / g) (2eq) were added to In 30ml of water, pass nitrogen gas to remove oxygen for 40min, add copper sulfate pentahydrate 0.008g (0.2eq) and sodium ascorbate 0.03(1eq), react at 37°C for 10h under nitrogen protection, take the three-dimensional scaffold out of the reaction solution, EDTA / ethanol (V / V=1:1) washing to remove copper ions and unreacted small molecules, vacu...

Embodiment 3

[0056] (1) Three-dimensional printing (T=205°C P=3.5bar) of polyurethane containing alkyne groups (Mn=35000), with an average pore size of 400 μm and a mass of 5 g, to obtain a three-dimensional polyurethane scaffold containing alkyne groups;

[0057] (2) Add 5 g of polyurethane three-dimensional scaffolds containing alkyne groups (alkyne group content 1 mmol / g) (1 eq) and 4 g of gelatin modified with azido groups (azido groups about 2 mmol / g) (1.6 eq) into 50 ml of water , deoxygenated with nitrogen for 30 minutes, added 0.003g of copper powder, reacted at 50°C for 15 hours under the protection of nitrogen, took the three-dimensional scaffold out of the reaction solution, washed with EDTA / ethanol (V / V=1:1) to remove copper powder and unreacted Small molecules, vacuum-dried, gelatin gel layer compounded on the surface of the polyurethane scaffold material to obtain a polyurethane scaffold bonded with gelatin;

[0058] (3) Add the gelatin-bonded polyurethane scaffold and 4 g of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com