Fermented konjac aromatic vinegar and production method thereof

A konjac and balsamic vinegar technology, applied in the field of bioengineering, can solve the problems of increased fermentation difficulty, viscosity of konjac balsamic vinegar, viscosity of fermentation liquid, etc., and achieves the effects of high cost performance, low price and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

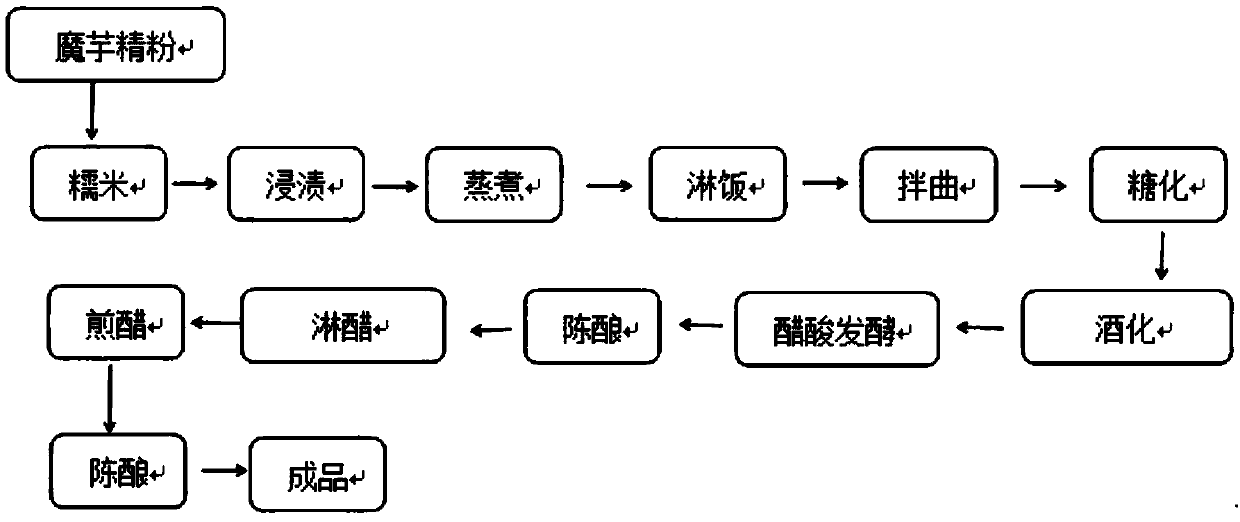

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: konjac powder pretreatment

[0040] Konjac fine powder is treated with an enzyme preparation compounded by β-mannanase and β-1,4-endoglucanase. Prepare 3 parts of konjac powder solution (dissolved in water) with the same concentration, and 3 parts of compound enzyme preparation prepared by β-mannanase and β-1,4-endoglucanase in a ratio of 2:3. The enzymatic hydrolysis conditions are as follows: add 2% enzyme preparation, the temperature is 25-30°C at room temperature, and enzymatic hydrolysis overnight. The prepared konjac powder solution is clear and transparent.

Embodiment 2

[0041] Embodiment 2: preparation of konjac health rice wine

[0042]Prepare konjac rice wine according to soaking rice, steaming rice, spreading cold, blanking, fermentation, pressing, decocting wine; wherein konjac fine powder is added in the blanking stage, and each material is calculated in parts by weight during blanking, adding 80 parts of glutinous rice, implementing Example 1 After pretreatment, 2 parts of konjac fine powder, 10 parts of natural koji, 3 parts of purebred cultured koji, 3 parts of Aspergillus niger, 100 parts of water, and 5 parts of Saccharomyces cerevisiae.

[0043] (1) Dipping: make the starch tissue absorb water and swell, and the volume increases by about 40%, which is convenient for full gelatinization. The ratio of rice to soaking water is 1:2.

[0044] (3) Mixing of raw materials: the above-mentioned pretreated konjac powder and glutinous rice are mixed.

[0045] (4) Cooking and pouring rice: through heating, the starch and konjac powder will ex...

Embodiment 3

[0048] Embodiment 3: preparation of konjac health-care balsamic vinegar

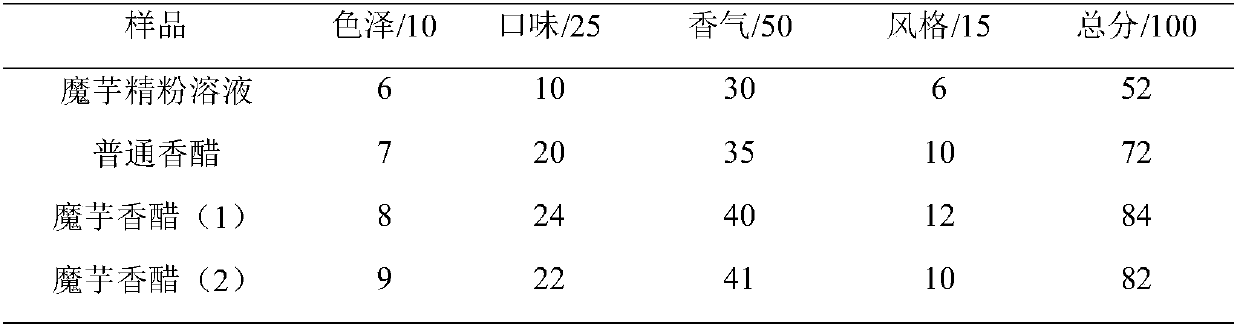

[0049] Utilize the rice wine obtained in Example 2 as raw material for acetic acid fermentation, adopt solid-state fermentation process, add 145 parts of bran, 8 parts of acetic acid bacteria, 75 parts of rice husk, and 5 parts of salt for fermentation to obtain konjac vinegar (1).

[0050] Acetic acid fermentation solid-state fermentation process: Mix rice husk, bran, and rice wine evenly, insert acetic acid bacteria, turn the unstrained spirits from the surface of the material every day within 1-2 days after inoculation, and the temperature is 35-40°C. Turn to the bottom of the material in 6-8 days. From the 8th to the 12th day, turn the unstrained spirits from the bottom every day, and the temperature will drop naturally. Raw vinegar is obtained after separation from the vinegar fermented grains, added with salt, and sterilized at 85°C for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com