Preparation method and application of a high-performance molybdenum disulfide/graphene oxide/iron oxide yellow composite catalyst

A composite catalyst, molybdenum disulfide technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of FeOOH/graphene oxide catalytic efficiency to be improved, and achieve good catalytic reduction effect , Improve the catalytic effect, the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

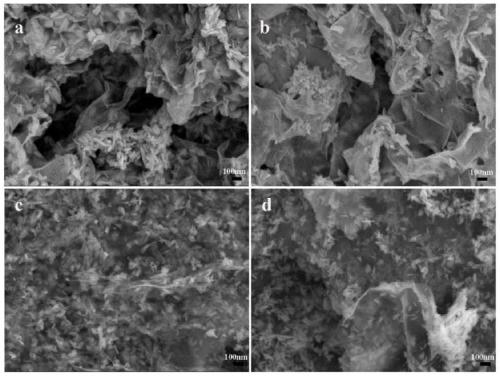

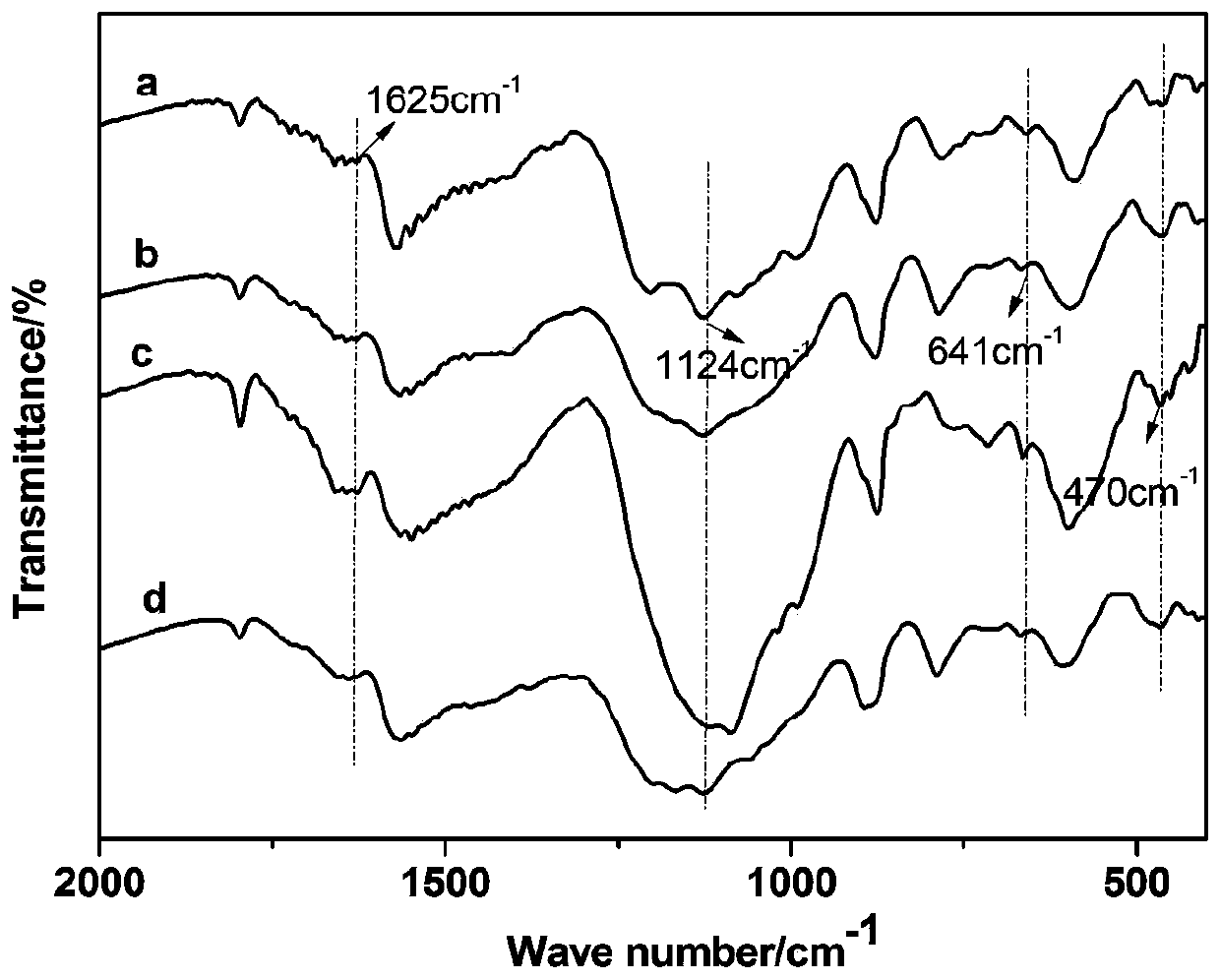

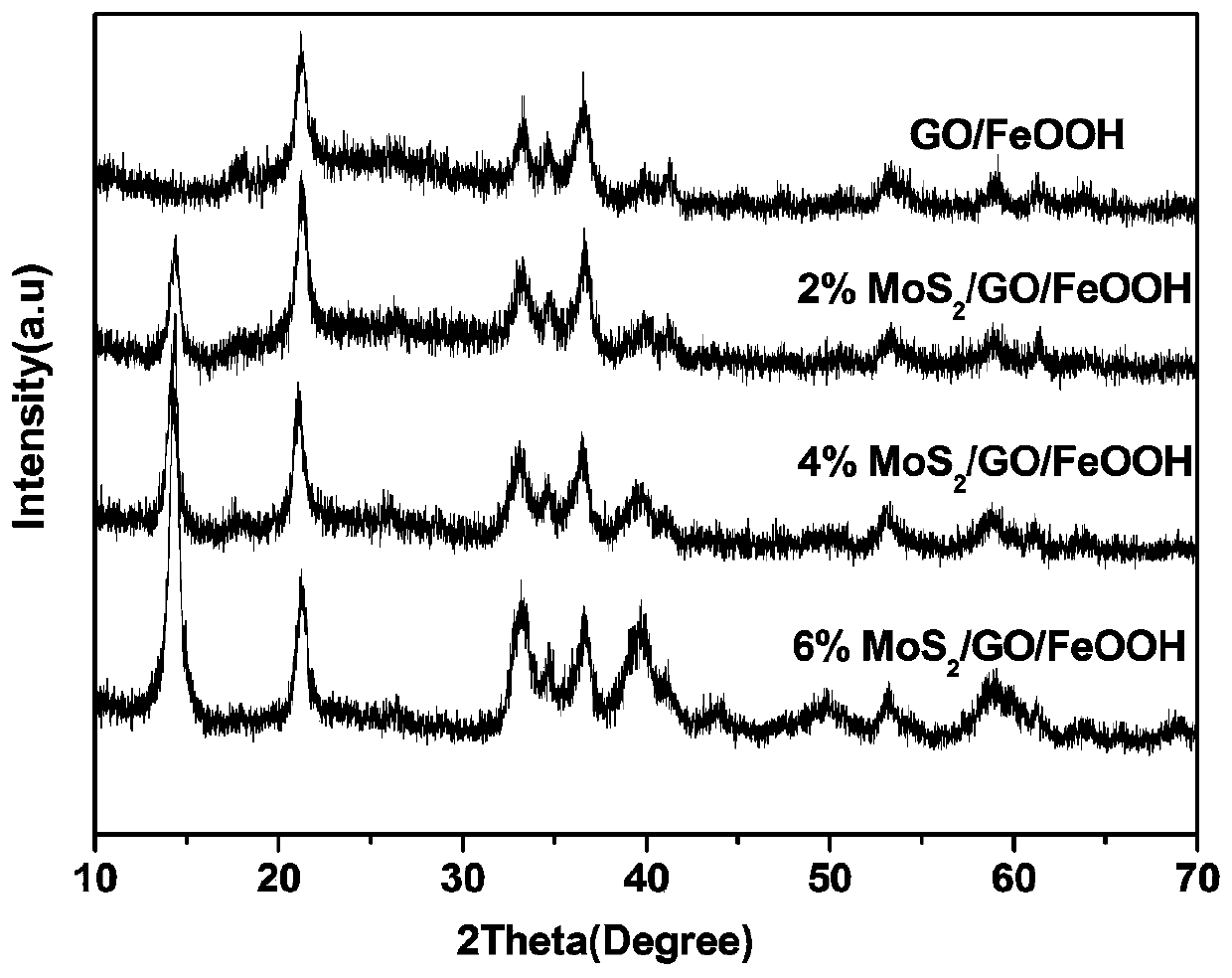

[0031]This embodiment prepares molybdenum disulfide / graphene oxide / iron oxide yellow composite catalyst according to the following steps:

[0032] Step 1: Preparation of Sheet Graphene Oxide

[0033] Sheet graphene oxide is prepared by the improved Hummers method, specifically as follows:

[0034] Mix 2g graphite powder with 1g NaNO 3 Add the powder into a three-necked flask, and then add 50 mL of concentrated H with a mass concentration of 98%. 2 SO 4 , with magnetic stirring in an ice-water bath, 6g KMnO 4 The solid particles were added to the three-necked flask in batches at 5°C, and after the addition was completed, the temperature was raised to 35°C and stirred for 24 hours; after the reaction, 100mL of deionized water was added to the reaction solution, and 250mL of deionized water was added after mixing evenly, and then Add 15mL of 30wt% hydrogen peroxide dropwise to the reaction solution, then add 200mL of 1mol / L HCl solution, stir and mix evenly, then centrifuge a...

Embodiment 2

[0041] This embodiment prepares molybdenum disulfide / graphene oxide / iron oxide yellow composite catalyst according to the same method as in Example 1, the difference is only that molybdenum disulfide, graphene oxide and ferrous sulfate are used in a mass ratio of 0.4:1 in step 3 : 18 ratio mixing, and then ultrasonically dispersed to obtain a composite solution, the resulting molybdenum disulfide / graphene oxide / iron oxide yellow composite catalyst is recorded as 2% MoS 2 / GO / FeOOH.

Embodiment 3

[0043] This embodiment prepares molybdenum disulfide / graphene oxide / iron oxide yellow composite catalyst according to the same method as in Example 1, the difference is only that molybdenum disulfide, graphene oxide and ferrous sulfate are used in a mass ratio of 0.8:1 in step 3 : 18 ratio mixing, and then ultrasonically dispersed to obtain a composite solution, the resulting molybdenum disulfide / graphene oxide / iron oxide yellow composite catalyst is recorded as 4% MoS 2 / GO / FeOOH.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com