Vacuum seal casting method for wind driven generator ductile iron hub

A technology for vacuum-sealed casting and wind turbines, applied in casting molding equipment, casting molds, casting mold components, etc., can solve problems such as low fatigue strength and surface micro-cracks, improve working conditions, improve environmental protection, and reduce production energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

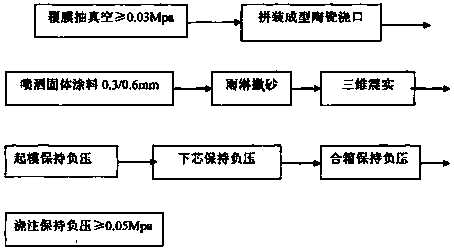

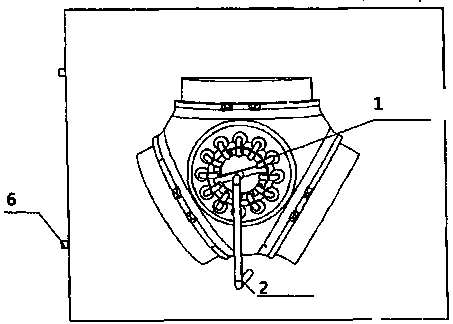

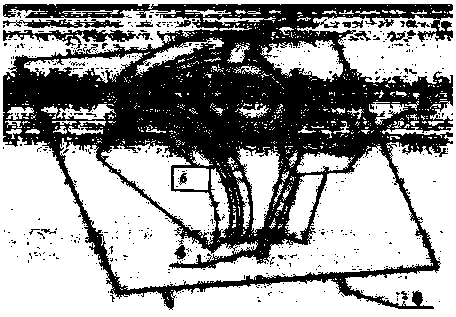

[0017] Shape it with the V method. Vacuum sealing molding (i.e. V method molding) is very different from traditional sand casting methods. It is a physical molding method that combines vacuum technology with sand casting and uses raw sand molding without water and binders. The cavity surface and the back of the sand mold are sealed by plastic film, and the negative pressure is generated by vacuum pump, which causes the pressure difference between the inside and outside of the sand mold to make the sand fasten and form. Press or stop pumping, and the molding sand will collapse to obtain castings. The process of V-method molding includes: manufacturing a template with a suction box and a suction hole; covering the plastic film baked in a plastic state on the template, and vacuum pumping to make the film closely adhere to the template; The sand box of the filter exhaust pipe is placed on the template covered with plastic film; the sand box is filled with dry quartz sand filled w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com