A kind of aminohydrocarbyl silane series decarburization solvent and decarburization method

An aminohydrocarbyl silane and decarburization technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of easy degradation of alcohol amine solvents, high equipment corrosion, and high regeneration energy consumption, and achieve high CO2 absorption. load, low desorption energy, and the effect of reducing decarbonization energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

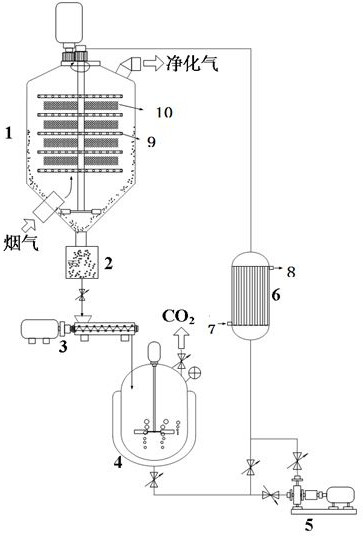

[0034] Such as figure 1 Set up a model test device to treat flue gas volume (dry basis) of 10 Nm 3 / h, the carbon dioxide content is 12%, and the flue gas temperature is 45°C. Aminosilane Decarburization Solvent Volume Flow 0.05 Nm 3 / h, where aminohydrocarbyl silane is NH 2 CH 2 SiMe 3 , wherein the co-solvent low polymerization degree polyethylene glycol mass content is 10%. The temperature in the kettle is 100 ℃, and the pressure in the kettle is 0.4 MPa (absolute pressure) for regeneration under pressure.

[0035] After decarbonization treatment, the carbon dioxide capture rate is 84.7%, and the unit energy consumption of carbon dioxide capture is 1.14 tons of steam / ton of CO 2 , decarburization solvent consumption (basically co-solvent degradation loss) 0.22 Kg / ton of carbon dioxide.

Embodiment 2

[0037] Such as figure 1 Set up a model test device to treat flue gas volume (dry basis) of 10 Nm 3 / h, the carbon dioxide content is 12%, and the flue gas temperature is 45°C. Aminosilane Decarburization Solvent Volume Flow 0.05 Nm 3 / h, where aminohydrocarbyl silane is NH 2 C 2 h 4 NHC 3 h 6 SiMe 3 , wherein the co-solvent low polymerization degree polyethylene glycol mass content is 10%. The temperature in the kettle is 100 ℃, and the pressure in the kettle is 0.4 MPa (absolute pressure) for regeneration under pressure.

[0038] After decarbonization treatment, the carbon dioxide capture rate is 81.5%, and the unit energy consumption of carbon dioxide capture is 1.14 tons of steam / ton of CO 2 , decarburization solvent consumption (basically co-solvent degradation loss) 0.22 Kg / ton of carbon dioxide.

Embodiment 3

[0040] Such as figure 1 Set up a model test device to treat flue gas volume (dry basis) of 10 Nm 3 / h, the carbon dioxide content is 12%, and the flue gas temperature is 45°C. Aminosilane Decarburization Solvent Volume Flow 0.05 Nm 3 / h, where aminohydrocarbyl silane is NH 2 CH 2 SiMe 3 and NH 2 C 2 h 4 NHC 3 h 6 SiMe 3 (molar ratio 1:1), wherein the co-solvent low polymerization degree polyethylene glycol mass content is 10%. The temperature in the kettle is 100 ℃, and the pressure in the kettle is 0.4 MPa (absolute pressure) for regeneration under pressure.

[0041] After decarbonization treatment, the carbon dioxide capture rate is 82.4%, and the unit energy consumption of carbon dioxide capture is 1.14 tons of steam / ton of CO 2 , decarburization solvent consumption (basically co-solvent degradation loss) 0.22 Kg / ton of carbon dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com