A kind of surface treatment method of aluminum alloy vehicle frame

A surface treatment, aluminum alloy technology, applied in the direction of pretreatment surface, surface coating liquid device, metal material coating process, etc., can solve the problems of poor weather resistance, poor corrosion resistance, high temperature resistance, etc., to improve mechanical Strength and high temperature resistance, salt water and water displacement resistance, corrosion and rust prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

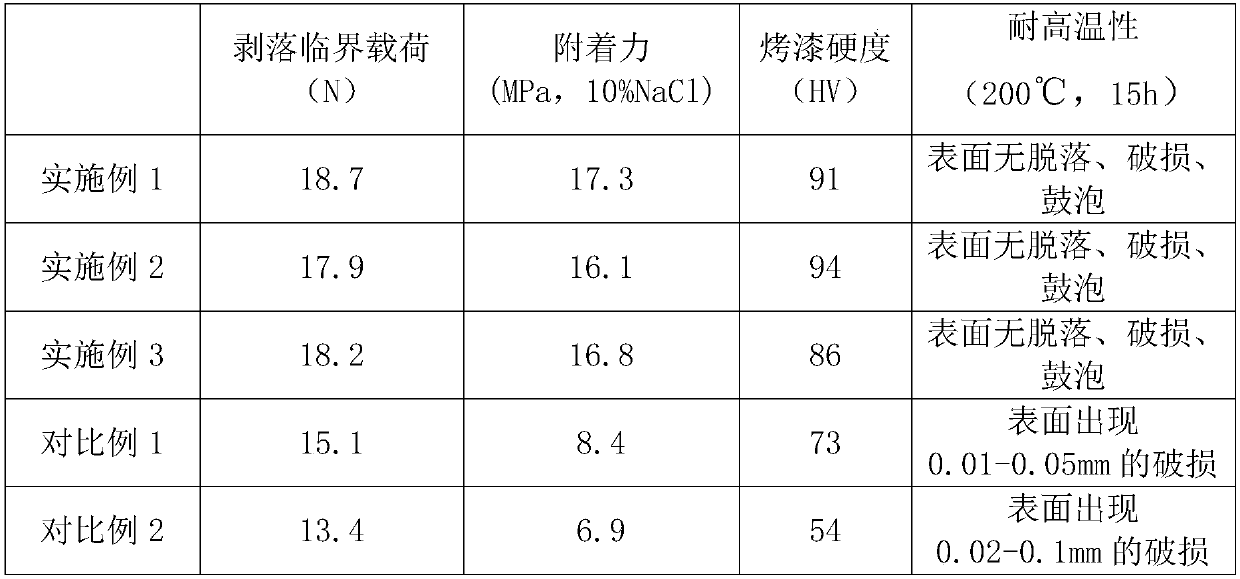

Examples

Embodiment 1

[0018] A method for surface treatment of an aluminum alloy vehicle frame, characterized in that it comprises the following steps;

[0019] S1. Pretreatment: Put the aluminum alloy frame in the dust removal room, remove dust and other sundries on the surface of the frame through a high-pressure dust blower, take it out, put it in a degreasing treatment solution at a temperature of 40°C for 35 minutes, and use Rinse with clean water at 40°C, soak in anti-rust treatment solution at room temperature for 8 minutes, wash with clean water for 2 minutes by ultrasonic vibration, and then dry at 65°C;

[0020] S2. Surface coating: place the aluminum alloy frame in the coating chamber, fill it with mixed gas after vacuuming, and excite electrons on the electrode plate under the condition of 800°C and RF power of 20W, so that the reaction chamber gas becomes plasma with a purity of ≥99.4 % of the aluminum block reacts on the surface of the frame to become nano-crystalline grains, and then...

Embodiment 2

[0023] A method for surface treatment of an aluminum alloy vehicle frame, characterized in that it comprises the following steps;

[0024] S1. Pretreatment: Put the aluminum alloy frame in the dust removal room, remove dust and other sundries on the surface of the frame through a high-pressure dust blower, take it out, put it in a degreasing treatment solution at a temperature of 40°C for 35 minutes, and use Rinse with clean water at 40°C, soak in anti-rust treatment solution at room temperature for 10 minutes, wash with clean water for 2 minutes by ultrasonic vibration, and then dry at 79°C;

[0025] S2. Surface coating: place the aluminum alloy frame in the coating chamber, vacuumize and fill the mixed gas, and the electrode plate excites electrons at 800°C and RF power of 30W, so that the reaction chamber gas becomes plasma with a purity of ≥99.4 % of the aluminum block reacts on the surface of the frame to become nano-crystalline grains, and then the frame is placed in a r...

Embodiment 3

[0028] A method for surface treatment of an aluminum alloy vehicle frame, characterized in that it comprises the following steps;

[0029] S1. Pretreatment: Put the aluminum alloy frame in the dust removal room, remove dust and other sundries on the surface of the frame through a high-pressure dust blower, take it out, put it in a degreasing treatment solution at a temperature of 40°C for 40 minutes, and use Rinse with clean water at 40°C, soak in anti-rust treatment solution at room temperature for 8-10 minutes, wash with clean water for 2 minutes by ultrasonic vibration, and then dry at 80°C;

[0030] S2. Surface coating: put the aluminum alloy frame in the coating chamber, vacuumize and fill the mixed gas, and the electrode plate excites electrons at 800°C and RF power of 25W, so that the reaction chamber gas becomes plasma with a purity of ≥99.4 % of the aluminum block reacts on the surface of the frame to become nano-crystalline grains, and then the frame is placed in a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com