Method of repairing shale gas fracturing waste liquid

A gas pressure and shale technology, applied in the field of plant-microbial remediation, can solve the problems of high technical difficulty, large amount of engineering, secondary pollution, etc., and achieve the effect of low technical requirements, small amount of engineering, and small environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1: Screening of Plants

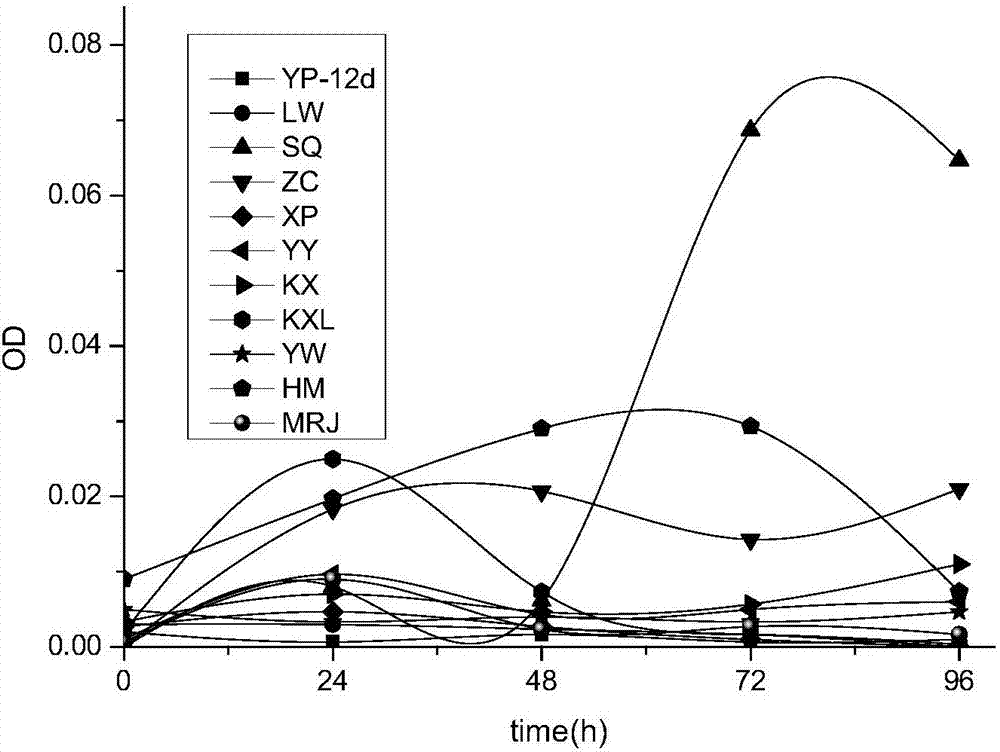

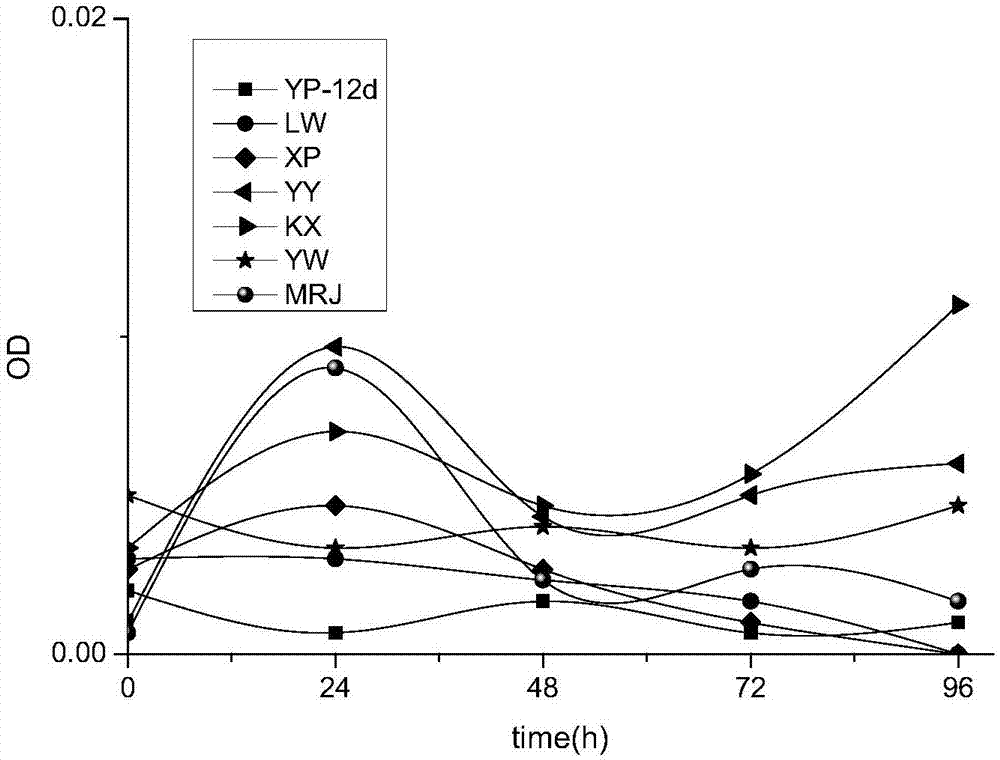

[0045] Ten plants with tenacious vitality were selected: three emergent plants reed (LW), cattail (XP) and water celery (SQ), submerged plant Zantaria (ZC), hygrophyte canna (MRJ) and iris (YW) , terrestrial plants ryegrass (HM), wild rape (YY) and water spinach (KX), and hollow lotus seedlings (KXL) that can grow in paddy fields, wetlands, and dry lands; said plants are all in natural non-polluted water bodies Live plants after 15 days of cultivation. Transplant its seedlings into the waste liquid discharged from shale gas fracturing. The bottle used in the experiment is a round glass bottle with a height of 50 cm and a diameter of 30 cm. The quality of water in each bottle is 1 kg, and the quality of young plants planted in each bottle is About 105g, the plants are fixed with plastic and floated on the water surface, the plant root system is completely immersed in the water, and three repeated horizontal experiments are done for eac...

Embodiment 2

[0047] Embodiment 2: the screening of microorganism

[0048] Because the shale gas discharge waste liquid has certain toxicity, after adding microorganisms with good water treatment effect, all the microorganisms will die. Therefore, the screening process of microorganisms is a synergy between plants and microorganisms.

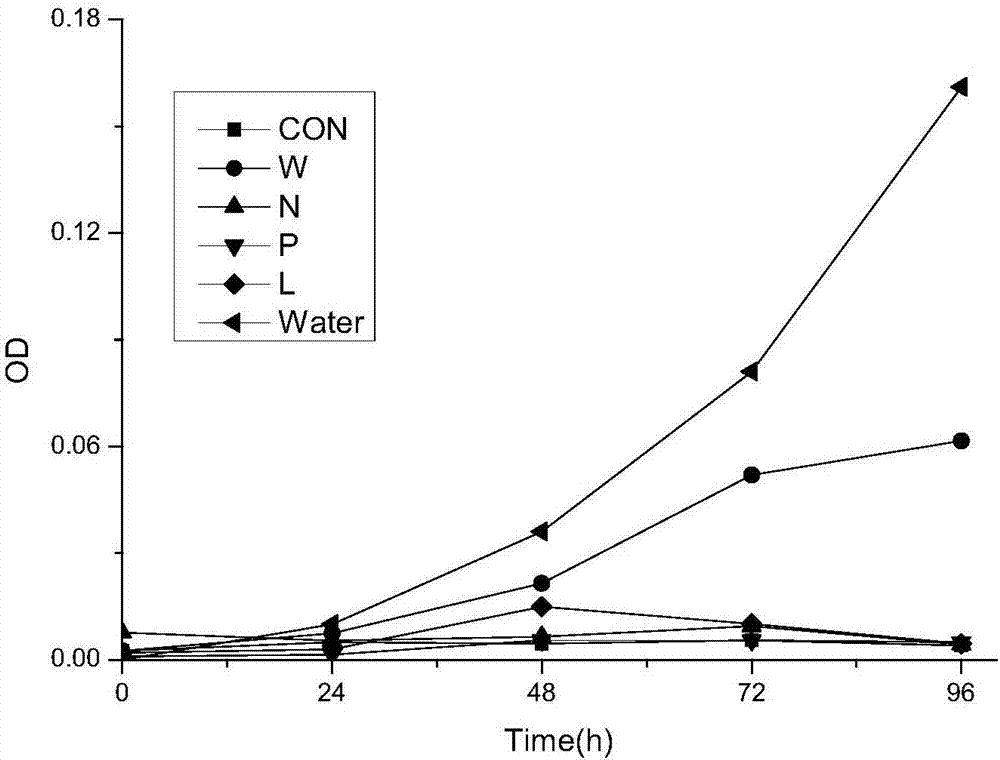

[0049] Select four kinds of microbial preparations for treating domestic sewage, compound bacterial agent (W), engineering bacteria (N), engineering bacteria (P) and engineering bacteria (L). Among them, the composite bacterial agent (W) is the strain selected by the Department of Hydrology and Water Resources of Yangtze University, including Bacteroides, Proteus, Firmicutes and Softicutes, and the Bacteroides, Proteobacteria, Firmicutes and Softicutes The mass ratio is 3:4:1:2; and the engineering bacteria (N), engineering bacteria (P) and engineering bacteria (L) are all engineering bacteria for sewage treatment, provided by Georgia Institute of Technolo...

Embodiment 3

[0051] Example 3: Optimization of influencing factors of phyto-microbial remediation system

[0052] In this experiment, four different influencing factors of microbial biomass, light color, temperature and plant quantity were set, and three kinds of red light, blue light and natural light were set; three different temperature environments of 20°C, 25°C and 30°C were adjusted; weighing 0, 100g, 150g and 200g plant amount of three different weight water celery; And 0mg / L, 450mg / L, 900mg / L, 1350mg / L four kinds of different concentrations of experimental bacteria agent (W) microbial solution. The plant water celery is a living plant after being cultivated in a natural pollution-free water body for 15 days. Transplant the seedlings into the waste liquid discharged from shale gas fracturing. The experiment uses a round glass bottle with a height of 50 cm and a diameter of 30 cm. The water in each bottle is 1 kg. The plants are fixed with plastic and float on the water surface , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com