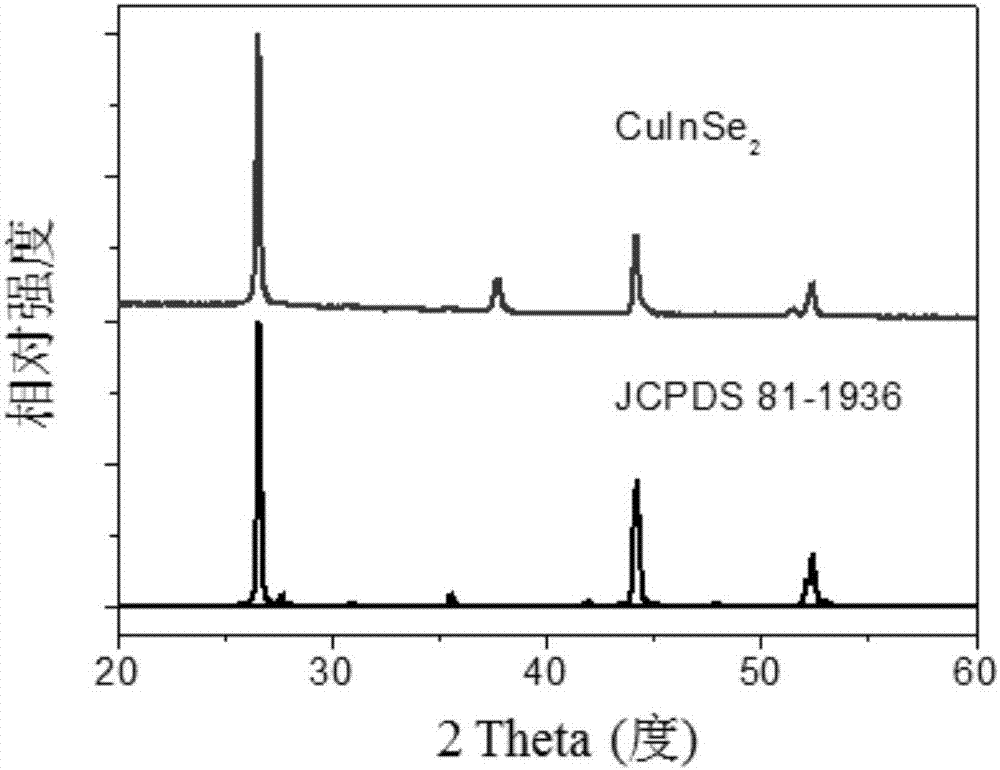

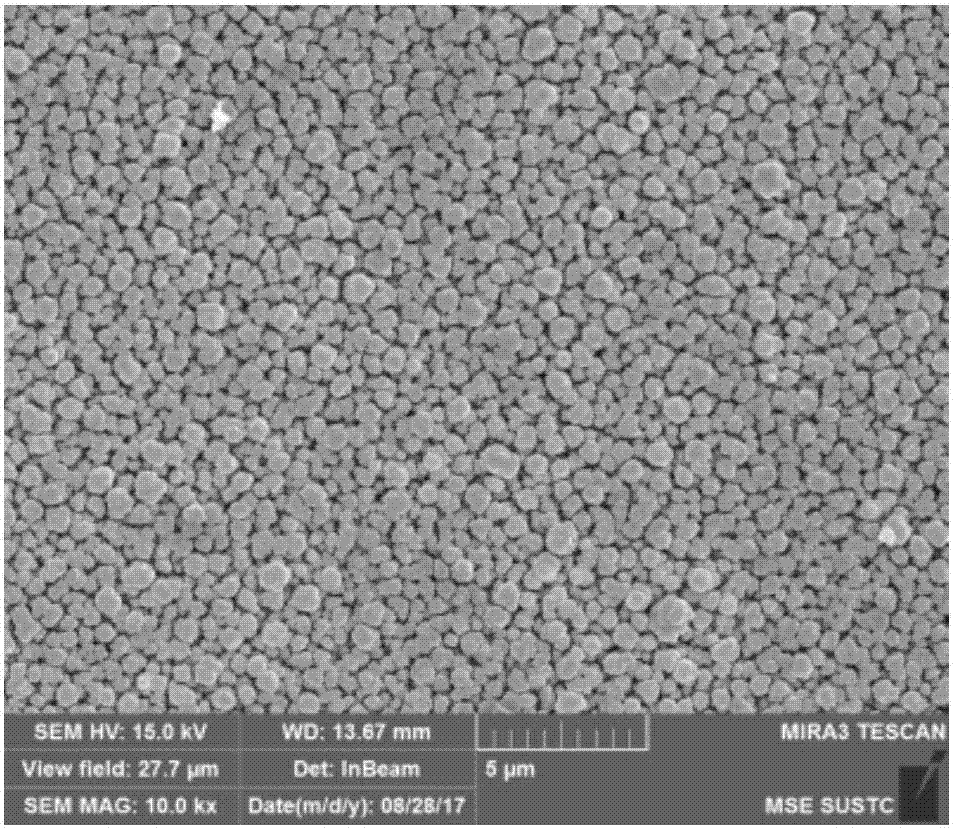

Preparation method of copper indium selenide counter electrodes for quantum dot sensitized solar cells

A technology for sensitization of solar cells and quantum dots, applied in photosensitive devices, electrolytic capacitors, circuits, etc., can solve problems such as contamination of electrolytes and photoanode, and achieve the effects of low cost, smooth surface, broad research value and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

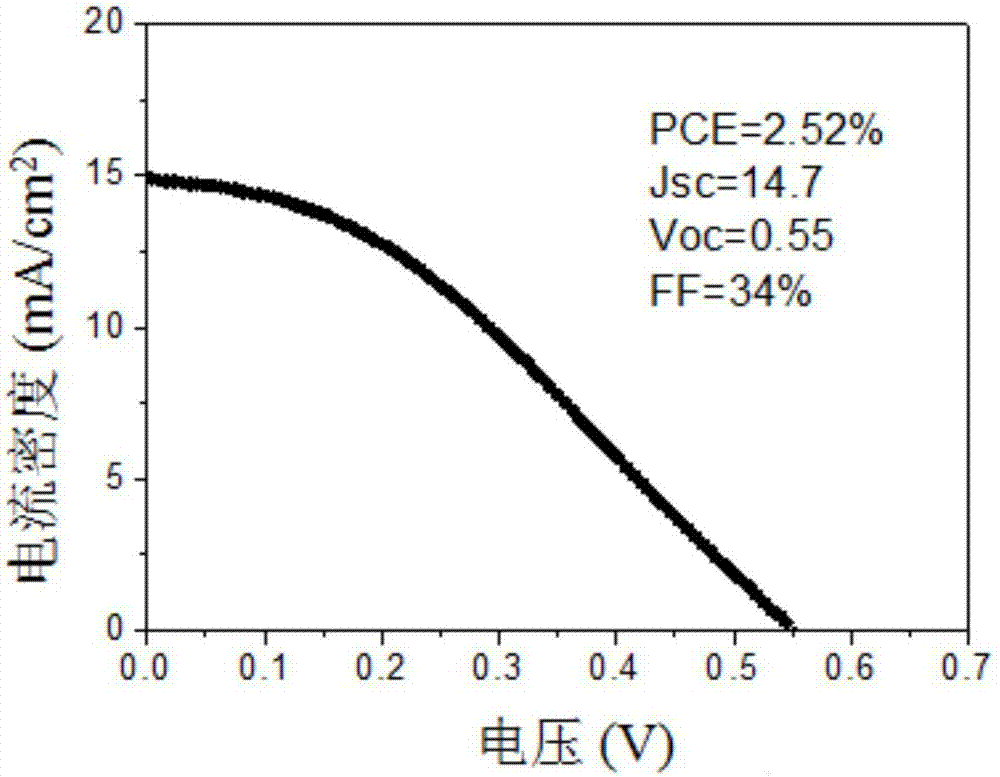

Examples

Embodiment 1

[0024] 1. Pretreatment

[0025] Cut the FTO conductive substrate into 4cm*2cm size, place them in decontamination solution, acetone, ethanol, and deionized water for ultrasonic cleaning for 15 minutes, then place them in an ultraviolet ozone cleaner for 20 minutes, and save them for later use;

[0026] 2. Preparation of electroplating solution

[0027] Citric acid monohydrate (C 6 h 8 o 7 ·H 2 O), copper sulfate pentahydrate (CuSO 4 ·5H 2 O), indium sulfate (In 2 (SO 4 ) 3 ), selenium dioxide (SeO 2 ) mixed with ultrapure water, using a magnetic stirrer to stir the mixed solution for 60 minutes to completely dissolve to obtain an electroplating solution; the molar concentrations of each component in the electroplating solution are respectively citric acid 0.4M, copper sulfate 0.006M, indium sulfate 0.006M, di Selenium oxide 0.01M.

[0028] 3. Electrochemical deposition

[0029] Add the electroplating solution prepared in step 2 into the electrolytic cell, use the p...

Embodiment 2

[0034] 1. Pretreatment

[0035] Cut the molybdenum-sputtered soda-lime glass substrate into 4cm*2cm, ultrasonically clean it in detergent solution, acetone, ethanol, and deionized water for 15 minutes, then place it in an ultraviolet ozone cleaner for 20 minutes, and store it for later use;

[0036] 2. Preparation of electroplating solution

[0037] Citric acid monohydrate (C 6 h 8 o 7 ·H 2 O), copper sulfate pentahydrate (CuSO 4 ·5H 2 O), indium sulfate (In 2 (SO 4 ) 3 ), selenium dioxide (SeO 2 ) mixed with ultrapure water, using a magnetic stirrer to stir the mixed solution for 60 minutes to completely dissolve to obtain an electroplating solution; the molar concentrations of each component in the electroplating solution are respectively citric acid 0.4M, copper sulfate 0.006M, indium sulfate 0.006M, di Selenium oxide 0.01M.

[0038] 3. Electrochemical deposition

[0039] Add the electroplating solution prepared in step 2 into the electrolytic cell, use the pretre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com