Preparing method of hollow-structure titanium oxide/silicon oxide composite photocatalytic material

A composite photocatalysis and silicon oxide technology, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Hollow structure and other problems, to achieve the effect of simple method flow, wide application prospect and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

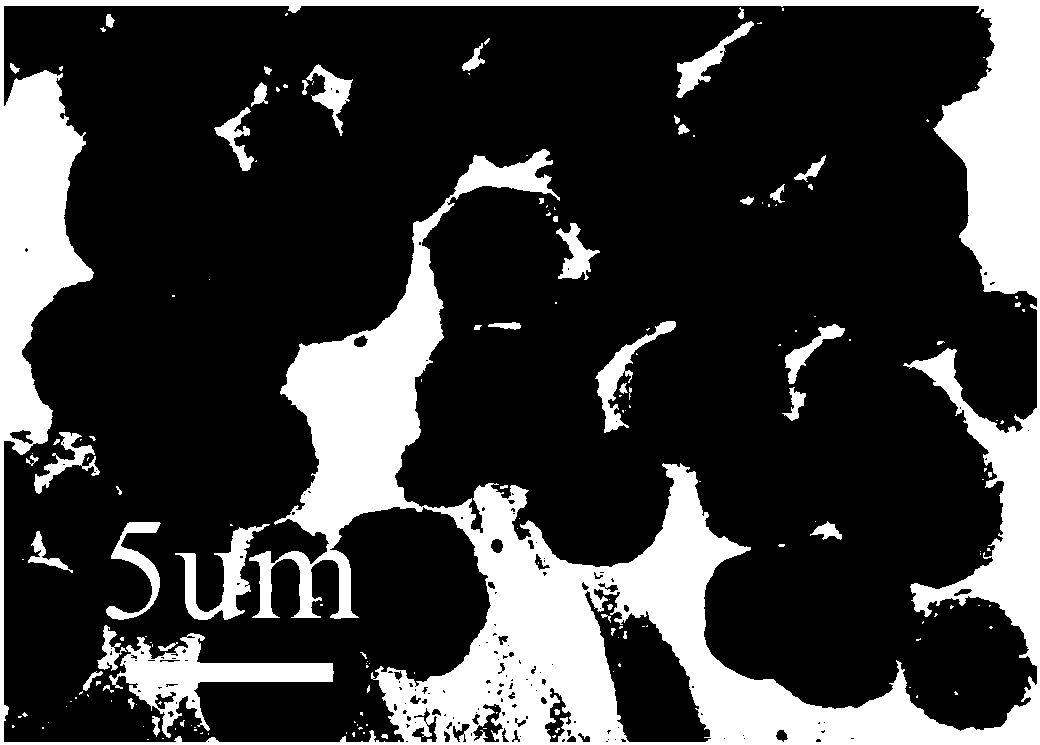

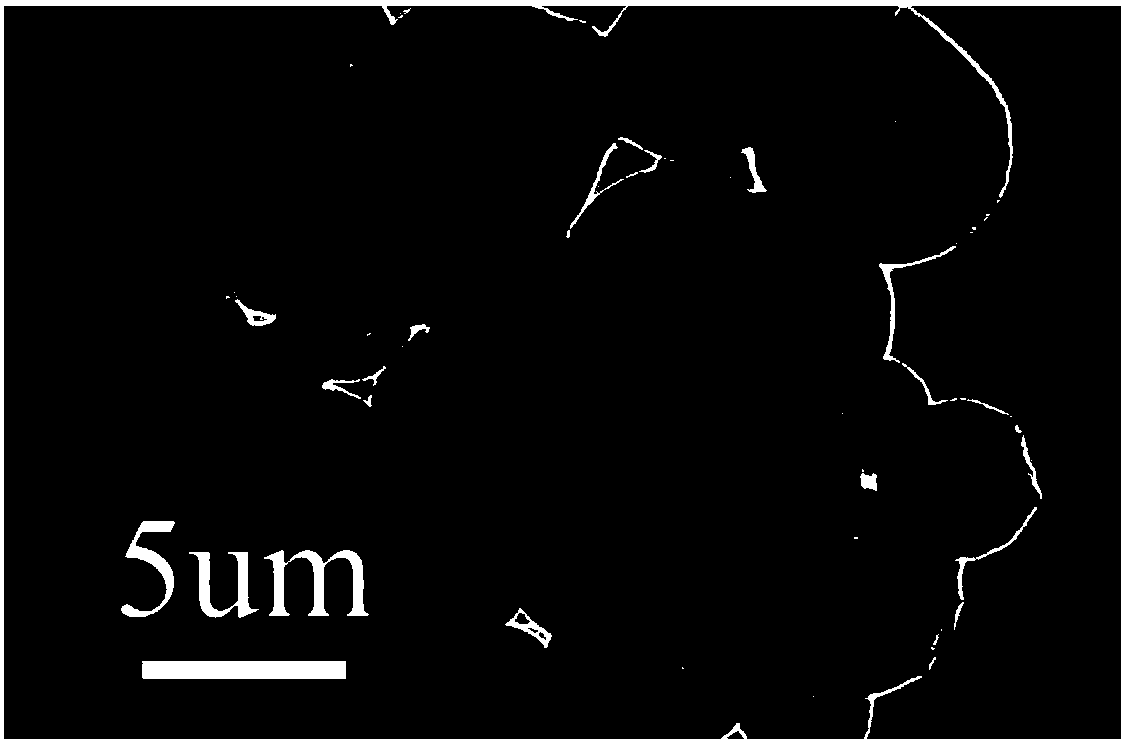

Image

Examples

preparation example Construction

[0033] In the preparation method according to the present invention, preferably the volume ratio of the ethanol phase to the water phase in step 1) is 0.5:1 to 0.8:1, more preferably 0.5:1 to 0.65:1. When the volume ratio of the ethanol phase to the water phase should be controlled between 0.5:1 and 0.8:1, the water-in-alcohol structure can be formed, and the titanium-peroxide-ammonia complex complex in the water phase is cross-linked to form a microsphere structure; low At 0.5, the water-in-alcohol structure cannot be formed, and the titanium-peroxide-ammonia composite complex becomes a blocky small particle agglomerate; more than 0.8, the titanium-peroxide-ammonia composite complex dissolves to form a homogeneous system.

[0034]Preferably, the mass ratio of the organosilane compound to the titanium-peroxide-ammonia composite complex microspheres in step 3) is 1:0.5 to 1:6, more preferably 1:1 to 1:3, most preferably It is 1:2. When the mass ratio of organosilane compound t...

Embodiment 1

[0038] First dissolve 80g of titanyl sulfate with 300ml of deionized water to obtain a titanyl sulfate aqueous solution; titrate the titanyl sulfate solution to a pH of 8.5 with a mass concentration of 36% ammonia water, centrifuge the precipitate, and then wash 3 times with deionized water to obtain Orthotitanic acid; be that 25% hydrogen peroxide aqueous solution dissolves washed 7g orthotitanic acid to obtain titanium peroxide aqueous solution with 10ml mass percent concentration, be that the pH of 4% ammoniacal liquor mediation is adjusted the titanium peroxide aqueous solution 11; add 25ml of absolute ethanol to the above solution system to form an emulsion structure.

[0039] The inlet temperature of the spray drying equipment is 20°C, the outlet temperature is 30°C, the feed rate is 50mL / h, and the compressed air flow rate is 500L / h to spray the above titanium hydrogen peroxide complex solution system, and then vacuum the solution Filter and dry to obtain titanium hydro...

Embodiment 2

[0043] Except that the mass ratio of the organosilane compound to the titanium-peroxide-ammonia composite complex microspheres is 1:6, the hollow structure SiO is obtained in the same manner as in Example 1. 2 -TiO 2 Composite photocatalytic material with a specific surface area of 852.31m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com