AgIn5S8-ZnS quantum dot, preparation method and uses thereof

An agin5s8-zns, quantum dot technology, applied in chemical instruments and methods, inorganic chemistry, luminescent materials, etc., can solve problems such as poor photocatalytic stability, achieve good dispersion, excellent photocatalytic activity, and facilitate mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Different ratios of L-cysteine and MPA AgIn 5 S 8 -ZnS photocatalyst preparation

[0023] AgIn 5 S 8 -ZnS nanocrystals are prepared by weighing out silver nitrate, indium nitrate, zinc acetate dihydrate, and different amounts of L-cysteine, mixed and dissolved in the aqueous solution, adjusted to pH 8.5 with NaOH, and then added thioethyl Stir the amide ultrasonically for 10 minutes, then add a different amount of MPA relative to L-cysteine, stir again for 10 minutes, and then hydrothermally react at 110 degrees for 4 hours. After the reaction, the mixture is dried by centrifugation and the mixed ligand is made into AgIn. 5 S 8 -ZnS nanocrystalline. Control the ratio of L-cysteine and MPA 0:10, 1:9, 2:8, 3:7, 5:5, 6:4, 8:2, 9:1, 10:0.

Embodiment 2

[0024] Example 2 AgIn 5 Characterization and Analysis of S8-ZnS Photocatalyst

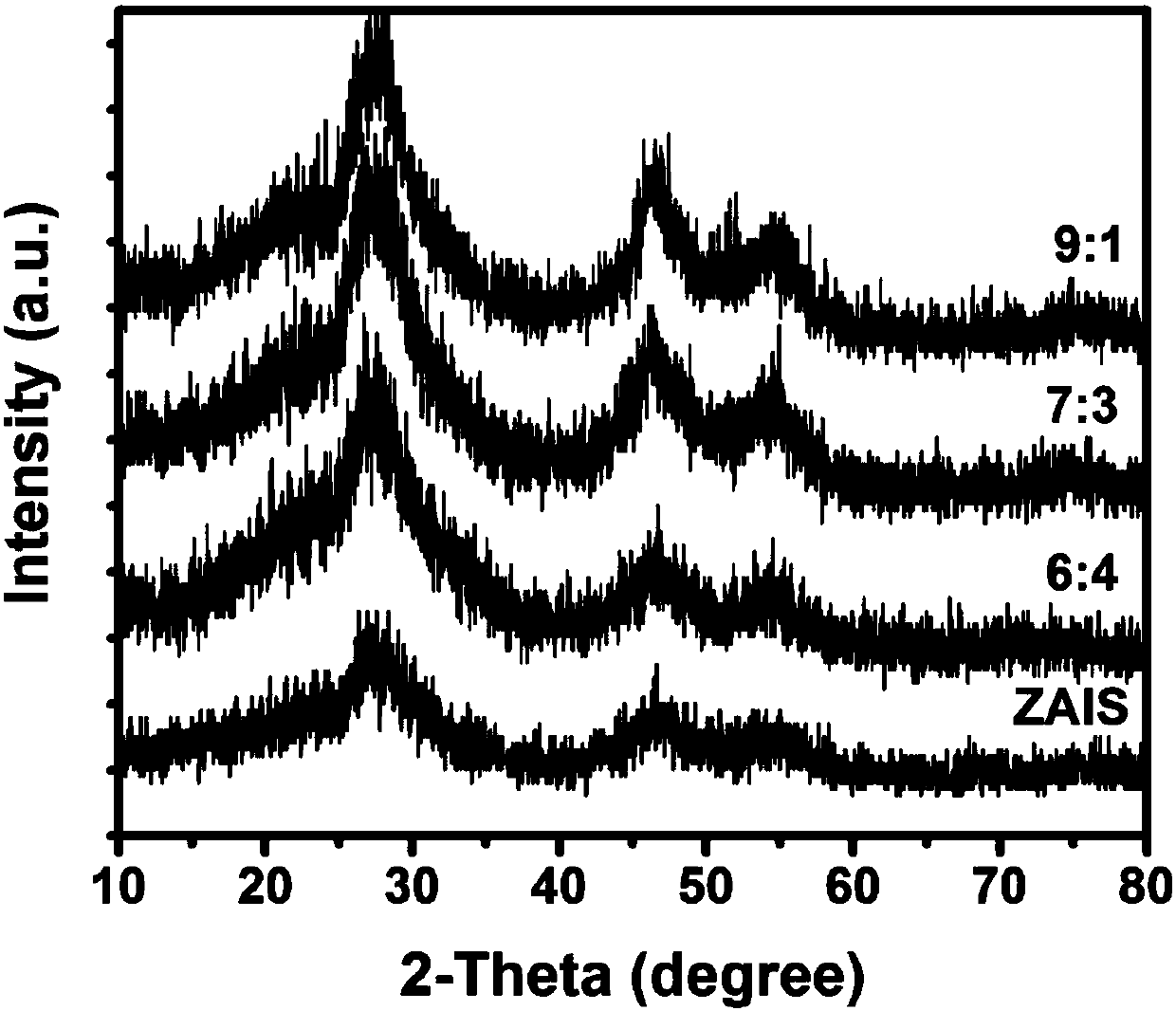

[0025] figure 1 , It can be seen from the figure that although the amount of L-cysteine and MPA changes, it is still mainly AgIn 5 S 8 -The peak of ZnS nanocrystal does not appear other impurity peaks.

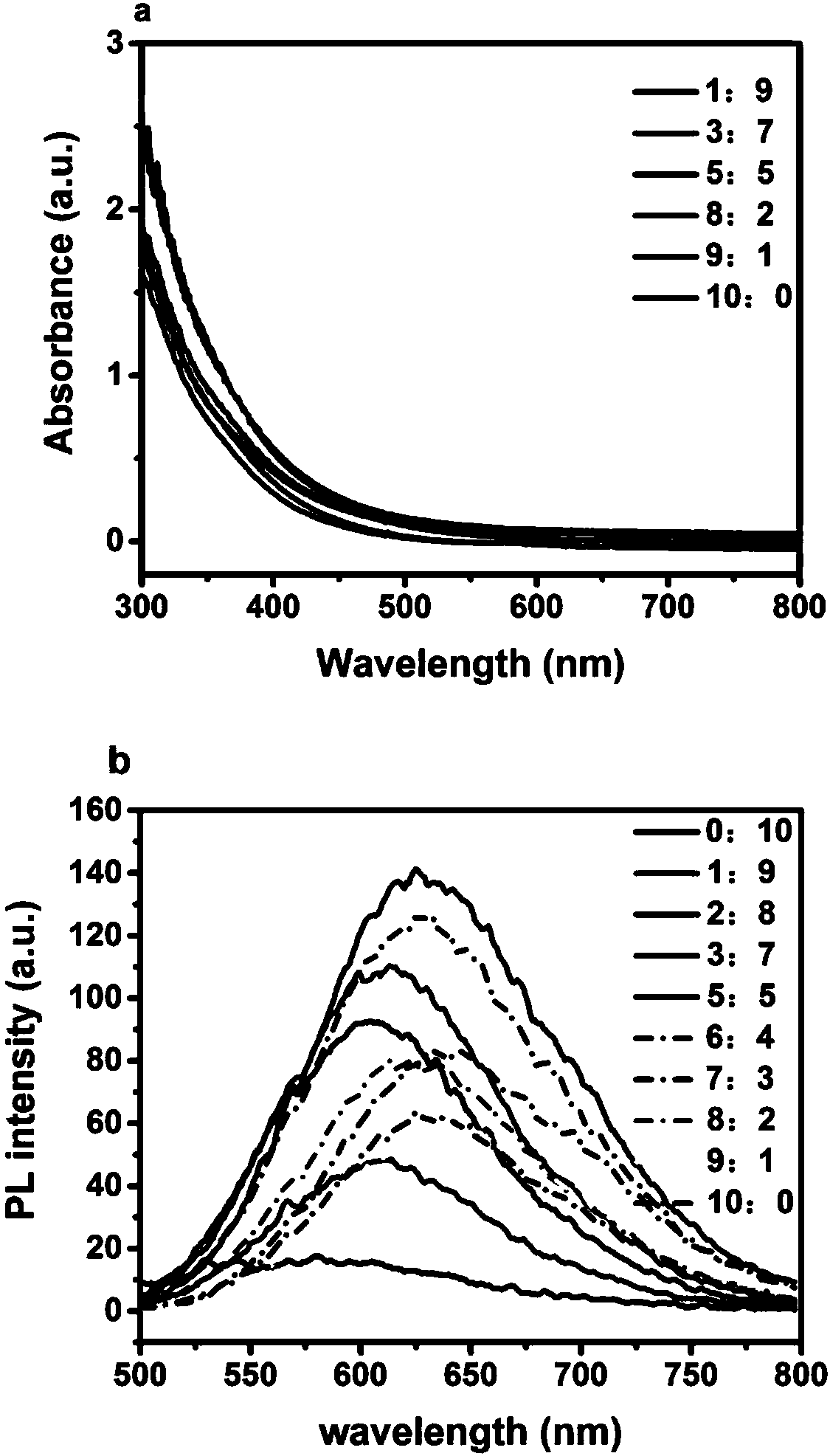

[0026] figure 2 From the figure, it can be seen that as the amount of MPA increases, it corresponds to the visible light region, while the fluorescence pattern shows a trend of first increasing and then decreasing. This phenomenon may be caused by the increase of MPA. The size increases.

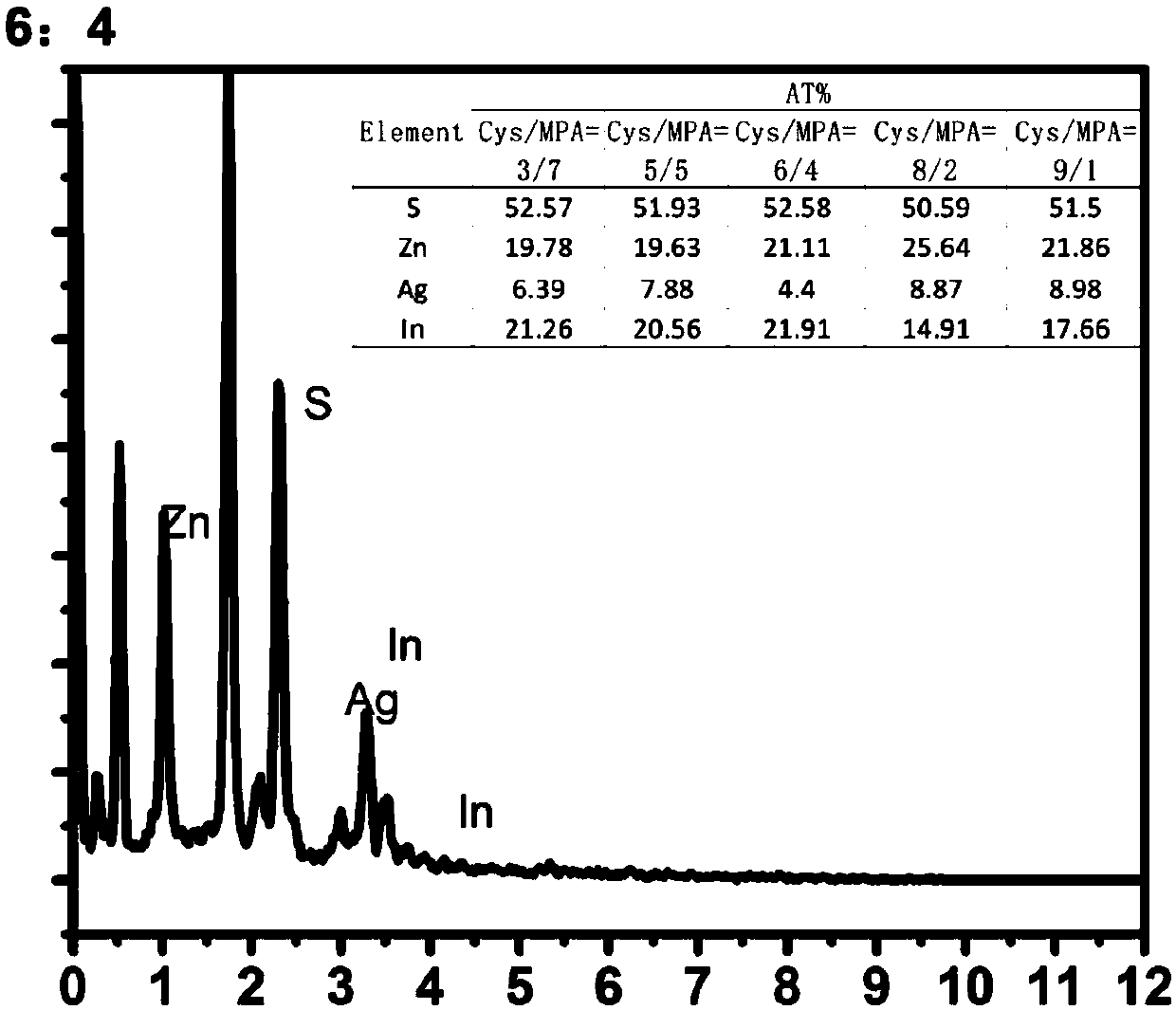

[0027] image 3 It can be seen from the figure that the percentage of elemental silver ions will decrease with the increase of MPA. It may be that MPA has replaced more atoms on the surface of quantum dots.

[0028] Figure 4 It can be seen from the figure that the quantum efficiency increases first and then decreases with the addition of MPA, and the quantum efficiency is the highest when the ratio is 5:5, indicating...

Embodiment 3

[0031] Example 3 AgIn 5 S 8 -ZnS photocatalyst for hydrogen production by visible light

[0032] (1) Configure 5M sodium sulfide solution.

[0033] (2) Weigh different proportions of AgIn 5 S 8 -ZnS catalyst sample 20mg, placed in the reaction flask.

[0034] (3) After that, weigh 0.4725g of sodium sulfite and 1ml of (1) in the reaction flask, and ultrasound for 5 minutes.

[0035] (4) Then put it on the nine channels for illumination, and take a sample every 1 hour for detection by gas chromatography. After data processing, you can get Figure 5 Diagram of hydrogen production. Under the condition of adding sacrificial agent, the optimized Cys / MPA=5:5 quantum dots visible light photocatalytic decomposition rate of water to produce hydrogen is 3.8 times that of pure l-cysteine synthesized quantum dots. Description of AgIn encapsulated by mixed ligand 5 S 8 -ZnS quantum dots further improve the hydrogen production performance of the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com