Method for extracting corn yellow pigment food additive through laser assistance

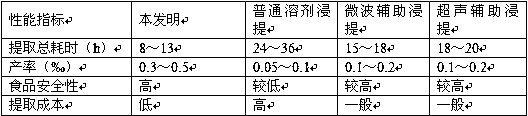

A technology of corn yellow pigment and food additives, which is applied in the food field, can solve the problems of high extraction conditions, narrow application range, complicated operation, etc., and achieve the effects of low equipment and raw material costs, accelerated extraction efficiency, and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

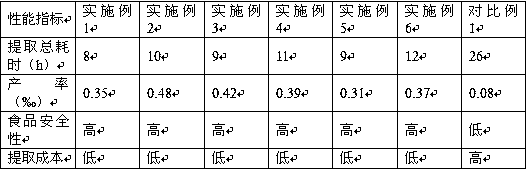

Examples

Embodiment 1

[0037](1) Grind corn gluten powder into superfine powder with a superfine pulverizer, stir and mix with water to prepare a suspension, adjust the pH value to 9.5, adjust the temperature to 53°C, add cellulase, and use biphenyl after 2 hours of enzymatic hydrolysis Three phenols are used to inactivate the enzyme, then the pH value is adjusted to 6.5, the temperature is adjusted to 52°C, neutral protease is added, and the enzymolysis is carried out for 2.5 hours; part, 80 parts of water; the particle size of corn gluten powder superfine powder is 0.5 μ m; the enzyme amount of cellulase is 1%; the enzyme amount of neutral protease is 1.2%;

[0038] (2) Centrifuge and filter the enzymatic solution, remove the supernatant, add ethanol to the resulting precipitate, mix well, and then use a laser to irradiate repeatedly, completely destroy the cell wall of the corn, and further activate the enzyme in the corn, The various pigment components are released to the greatest extent, and di...

Embodiment 2

[0042] (1) Use a superfine pulverizer to pulverize corn gluten powder into superfine powder, stir and mix with water to prepare a suspension, adjust the pH value to 9, adjust the temperature to 54°C, add cellulase, and use continuous Glucoglucinol is used to inactivate the enzyme, then the pH value is adjusted to 6.5, the temperature is adjusted to 52°C, neutral protease is added, and the enzymolysis is carried out for 3.5 hours; 15 parts, 85 parts of water; the particle size of superfine corn gluten powder is 0.8 μm; the enzyme amount of cellulase is 1.4%; the enzyme amount of neutral protease is 1.1%;

[0043] (2) Centrifuge and filter the enzymatic solution, remove the supernatant, add ethanol to the resulting precipitate, mix well, and then use a laser to irradiate repeatedly, completely destroy the cell wall of the corn, and further activate the enzyme in the corn, The various pigment components are released to the greatest extent, and dissolved in ethanol, centrifuged af...

Embodiment 3

[0047] (1) Grind corn gluten powder into superfine powder with a superfine pulverizer, stir and mix with water to prepare a suspension, adjust the pH value to 9.5, adjust the temperature to 53°C, add cellulase, and use continuous Glucoglucinol is used to inactivate the enzyme, then the pH value is adjusted to 7.5, the temperature is adjusted to 49°C, neutral protease is added, and the enzymolysis is carried out for 3 hours; parts, 88 parts of water; the particle size of superfine corn gluten powder is 0.6 μm; the enzyme amount of cellulase is 1.2%; the enzyme amount of neutral protease is 1.2%;

[0048] (2) Centrifuge and filter the enzymatic solution, remove the supernatant, add ethanol to the resulting precipitate, mix well, and then use a laser to irradiate repeatedly, completely destroy the cell wall of the corn, and further activate the enzyme in the corn, The various pigment components are released to the greatest extent, and dissolved in ethanol, centrifuged after 22min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com