Preparation method and application of high-specific-surface porous carbon modified by coal-tar pitch

A technology of coal tar pitch and high specific surface area, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems that hinder the precise control of carbon material structure, high molecular aromaticity and condensation degree, and limit the application scope of carbon materials, etc. problems, to achieve the effect of improving the catalytic graphitization ability of porous carbon, high specific surface area, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

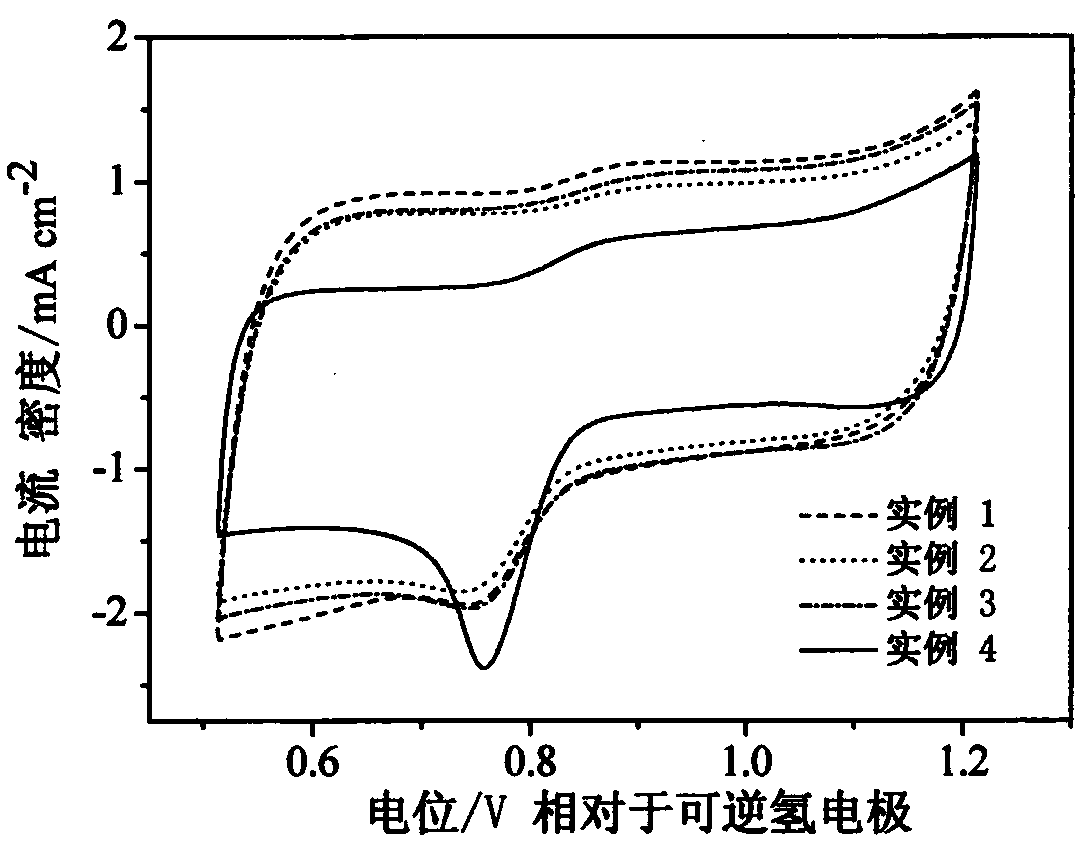

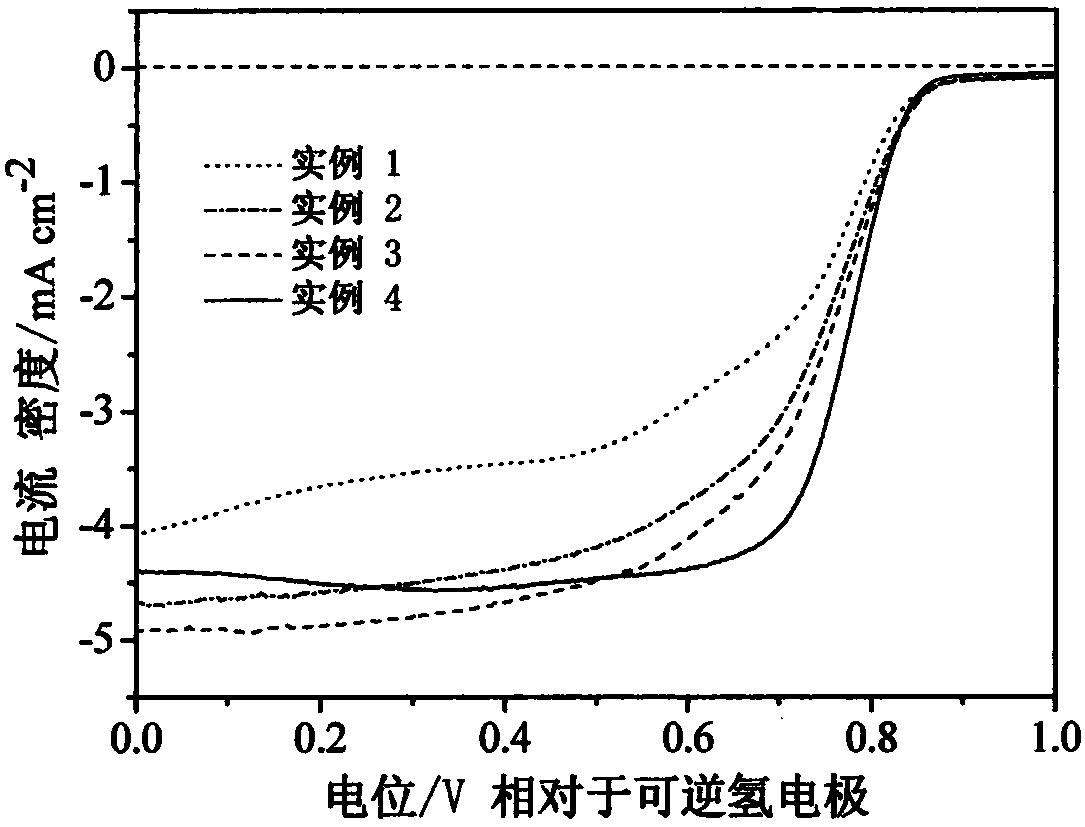

Embodiment 1

[0037] The invention discloses a method for preparing porous carbon with high specific surface area modified by coal tar pitch. The specific steps are: directly activate the medium-temperature pitch in one step to obtain the pitch-based activated carbon. Add 1 mL of ammonia to 20 mL of deionized water. Add 0.125g of pitch-based activated carbon into the above solution, stir evenly, and ultrasonicate for 30min. Put the ultrasonicated mixture in a reaction kettle, which is a 50mL hydrothermal reaction kettle with a polytetrafluoroethylene liner and a stainless steel jacket, and put the reaction kettle in an oven at 80°C for 1 hour of hydrothermal reaction , the obtained solid was washed with deionized water until neutral, centrifuged, and the obtained solid was dried in an oven at 60°C for 8 hours to obtain a black solid powder, which was ground and placed in a tube furnace at a calcination temperature of 700°C. The time is 1 hour, and the coal tar pitch modified porous carbon ...

Embodiment 2

[0039]The invention discloses a method for preparing porous carbon with high specific surface area modified by coal tar pitch. The specific steps are: directly activate the medium-temperature pitch in one step to obtain the pitch-based activated carbon. Weigh 0.015625g of cobalt nitrate hexahydrate and dissolve in 30mL of deionized water, and add 1.5mL of ammonia water at the same time to form a homogeneous solution. Add 0.125g of pitch-based activated carbon into the above solution, stir evenly, and ultrasonicate for 30min. Place the ultrasonicated mixture in a reaction kettle, which is an 80mL hydrothermal reaction kettle with a polytetrafluoroethylene liner and a stainless steel jacket, and put the reaction kettle in an oven at 100°C for 1.5 hours of hydrothermal reaction , the resulting solid was washed with deionized water to neutrality, centrifuged, and the resulting solid was dried in an oven at 60°C for 8 hours to obtain a black solid powder, which was ground and place...

Embodiment 3

[0041] The invention discloses a method for preparing porous carbon with high specific surface area modified by coal tar pitch. The specific steps are: directly activate the medium-temperature pitch in one step to obtain the pitch-based activated carbon. Weigh 0.03125g of cobalt nitrate hexahydrate and dissolve in 40mL of deionized water, and add 2mL of ammonia water at the same time to form a homogeneous solution. Add 0.125g of pitch-based activated carbon into the above solution, stir evenly, and ultrasonicate for 30min. Put the ultrasonicated mixture in a reaction kettle, which is a 100mL hydrothermal reaction kettle with a polytetrafluoroethylene liner and a stainless steel jacket, and put the reaction kettle in an oven at 120°C for 2 hours of hydrothermal reaction , the resulting solid was washed with deionized water to neutrality, centrifuged, and the resulting solid was dried in an oven at 60°C for 8 hours to obtain a black solid powder, which was ground and placed in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com