A kind of method for preparing antibacterial collagen based on safrole epoxidation modification

A safrole and epoxidation technology, which is applied in the preparation methods of peptides, chemical instruments and methods, organic chemistry, etc., can solve the problems such as the lack of long-term effect of continuous dissolution antibacterial mode, affecting the biocompatibility of natural collagen, and achieve antibacterial effects. Functional long-lasting, mild response conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

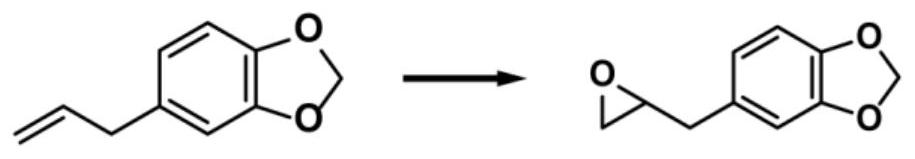

[0021] (1) Safrole epoxidation modification:

[0022] Dissolve 12 parts of m-chloroperoxybenzoic acid in 100 parts of dichloromethane, add 8 parts of safrole, and stir at 20°C for 24 hours; thereafter, the product is washed 3 times with 2% aqueous sodium hydroxide solution, and then used to remove Ionized water was washed 3 times; finally, the oil layer was dried with anhydrous magnesium sulfate, filtered and distilled under reduced pressure to obtain epoxidized safrole;

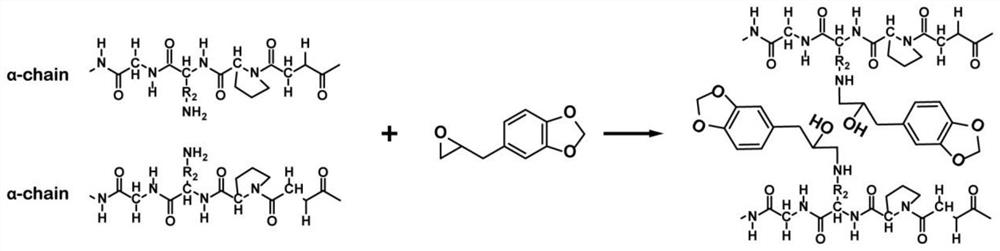

[0023] (2) Epoxidized safrole grafted modified collagen:

[0024] Dissolve 10 parts of collagen in 0.2mol / L acetic acid aqueous solution, then coat the above mixture to form a film, and dry it at 20°C to constant weight; then soak the above collagen film in pH value 7, epoxidized safrole concentration 3% aqueous solution; after 12 hours, the collagen film was taken out and washed three times with deionized water to obtain epoxidized safrole grafted modified collagen.

[0025] The results of infrared spectr...

Embodiment 2

[0027] (1) Safrole epoxidation modification:

[0028] Dissolve 15 parts of iodosobenzene in 150 parts of chloroform, add 10 parts of safrole, and stir for 20 hours at 25°C; after this, the product is washed 4 times with 5% potassium hydroxide aqueous solution, and then washed with deionized water for 5 time; at last, the oil layer is dried with anhydrous magnesium sulfate, and after filtration, vacuum distillation obtains epoxidized safrole;

[0029] (2) Epoxidized safrole grafted modified collagen:

[0030] Dissolve 15 parts of collagen in 0.4 mol / L acetic acid aqueous solution, then coat the above mixture to form a film, and dry it at 22°C to constant weight; then soak the above collagen film in pH 8, epoxidized safrole concentration 7% aqueous solution; after 24 hours, the collagen film was taken out and washed 4 times with deionized water to obtain epoxidized safrole grafted modified collagen.

[0031] The results of infrared spectroscopy and circular dichroism experimen...

Embodiment 3

[0033] (1) Safrole epoxidation modification:

[0034] Dissolve 20 parts of tert-butanol peroxide in 200 parts of carbon tetrachloride, add 12 parts of safrole, and stir at 30° C. for 12 hours; after this, the product is washed 5 times with 7% aqueous sodium bicarbonate solution, and then used to remove Washing with deionized water for 5 times; finally, the oil layer was dried with anhydrous magnesium sulfate, filtered and distilled under reduced pressure to obtain epoxidized safrole;

[0035] (2) Epoxidized safrole grafted modified collagen:

[0036] Dissolve 20 parts of collagen in 0.5 mol / L acetic acid aqueous solution, then coat the above mixture to form a film, and dry it at 25°C to constant weight; then soak the above collagen film in pH 9, epoxidized safrole concentration 10% aqueous solution; after 48 hours, the collagen film was taken out and washed 5 times with deionized water to obtain epoxidized safrole grafted modified collagen.

[0037] The results of infrared s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com