Method for adsorbing six heavy metals in water environment based on magnetic graphene oxide

A graphene and heavy metal adsorption technology, applied in the field of environmental protection and nanomaterials, can solve the problems of low adsorption rate and slow treatment time of heavy metal wastewater, and achieve the effect of improving purity, simple method and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Synthesis of graphene oxide: In an ice bath, 1.0g of graphite powder, 2.5g of NaNO 3 and 100 mL of concentrated H 2 SO 4 Mix in beaker for 30min. Slowly add 3g of KMnO 4 , the temperature was gradually raised to 35°C and stirred for 4h, then gradually raised to 60°C and stirred for 2h. Then the above mixture was added into ultrapure water, stirred at 98 °C for 1 h, and 10 mL of 30% H 2 o 2 , the color of the mixture changed to bright yellow and was filtered. Wash with 5% HCl to remove heavy metals, wash with ultrapure water to remove excess acid, and finally ultrasonically disperse in water and freeze-dry for 24 hours.

[0027] The synthesis process of magnetic graphene oxide:

[0028] Weigh 1.736g of NH 4 Fe(SO 4 ) 2 12H 2 O, 0.784g (NH 4 ) 2 Fe(SO 4 ) 2 ·6H2 O, in N 2 Under the protection condition of , add it into 100mL of ultrapure water, stir evenly with magnetic force, and the temperature is 70°C. Use 1M NH 4 OH to adjust the pH value to 3, and t...

Embodiment 2

[0030] Example 2 Using the magnetic graphene oxide prepared in Example 1 to adsorb heavy metal ions

[0031] Using NaOH and HNO 3 Regulated to contain heavy metal Cr 6+ 、Cd 2+ , Pb 2+ 、Cu 2+ 、As 5+ , Hg 2+ To determine the pH value of the solution, weigh the magnetic graphene oxide and add it to the solution, oscillate evenly and time it, take it out after a period of time, and use inductively coupled plasma mass spectrometry (ICP-MS) to measure the content of six heavy metals.

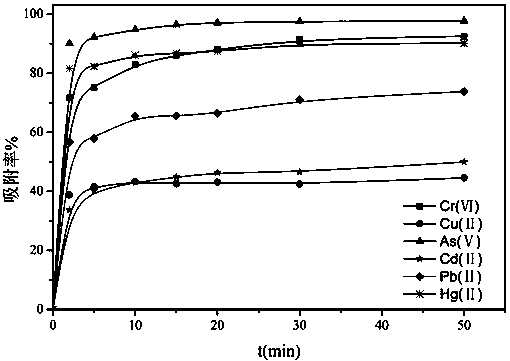

[0032] Optimization of adsorption process time: configure 100mL containing about 40ng / mL Cr 6+ 、Cd 2+ , Pb 2+ 、Cu 2+ 、As 5+ , Hg 2+ For the mixed solution of heavy metal ions, take out 5mL before adsorption, and wait for the test. Take 24mg of magnetic graphene oxide and add it to the mixed solution of heavy metal ions, and shake it. The adsorption time is 2, 5, 10, 15, 20, 30, 50min, take out 5mL, and pass through a microporous membrane with a pore size of 0.22μm. The concentration of th...

Embodiment 3

[0037] Elution of heavy metals on magnetic graphene oxide by 0.02M HCl in different time periods: six 40mL solutions with a pH value of 6-7 were prepared, containing about 50ng / mL of Cr 6+ 、Cd 2+ , Pb 2+ 、Cu 2+ 、As 5+ , Hg 2+ heavy metal. Take out 5mL before adsorption, to be tested; weigh 10mg of magnetic graphene oxide and add them to the mixed solution, vortex for 10min, use a magnet to separate, pour out to be tested; add 1mL of 0.02M HCl eluent, and the oscillation time is respectively 5, 15, 30, 60, 120min, take out the measured concentration, and calculate the elution rate. Effect of 0.02M HCl on Cd on magnetic graphene oxide at different times 2+ Changes in elution rate as Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com