Preparation method and application of high-superhydrophobicity organosilane polymer coating

A polymer coating and organosilane technology, which is applied in coatings, antifouling/underwater coatings, paints containing biocides, etc., can solve the problems of complex chemical substances, expensive, long preparation cycle, etc., and achieve the preparation method Simple, low surface tension, stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

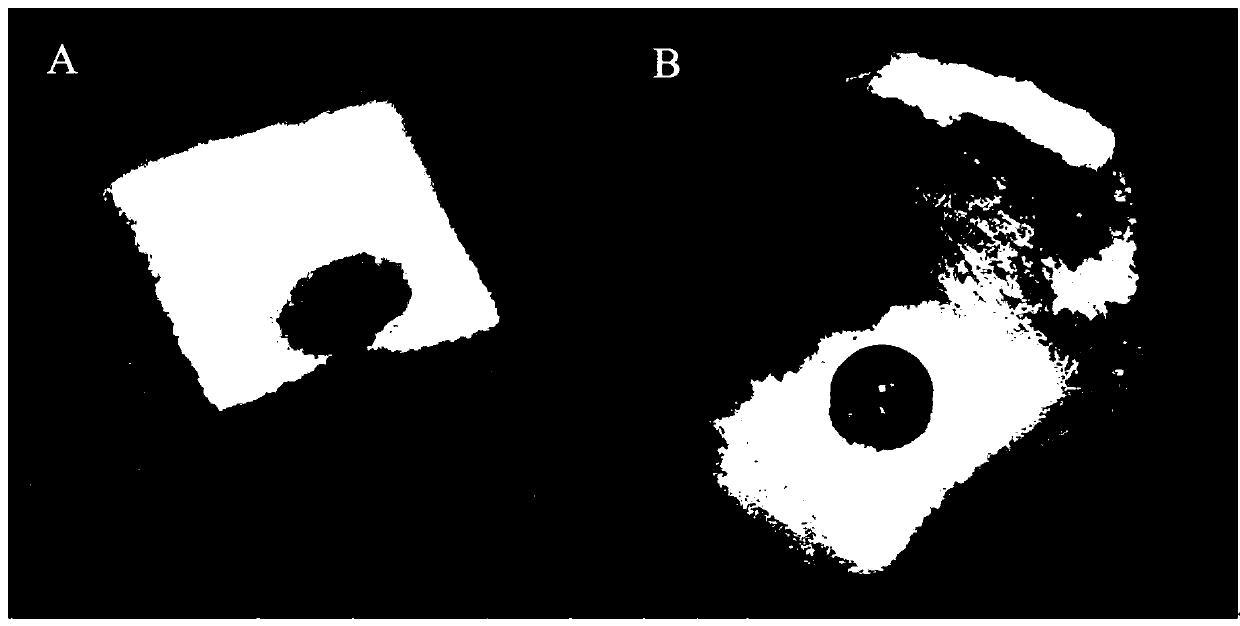

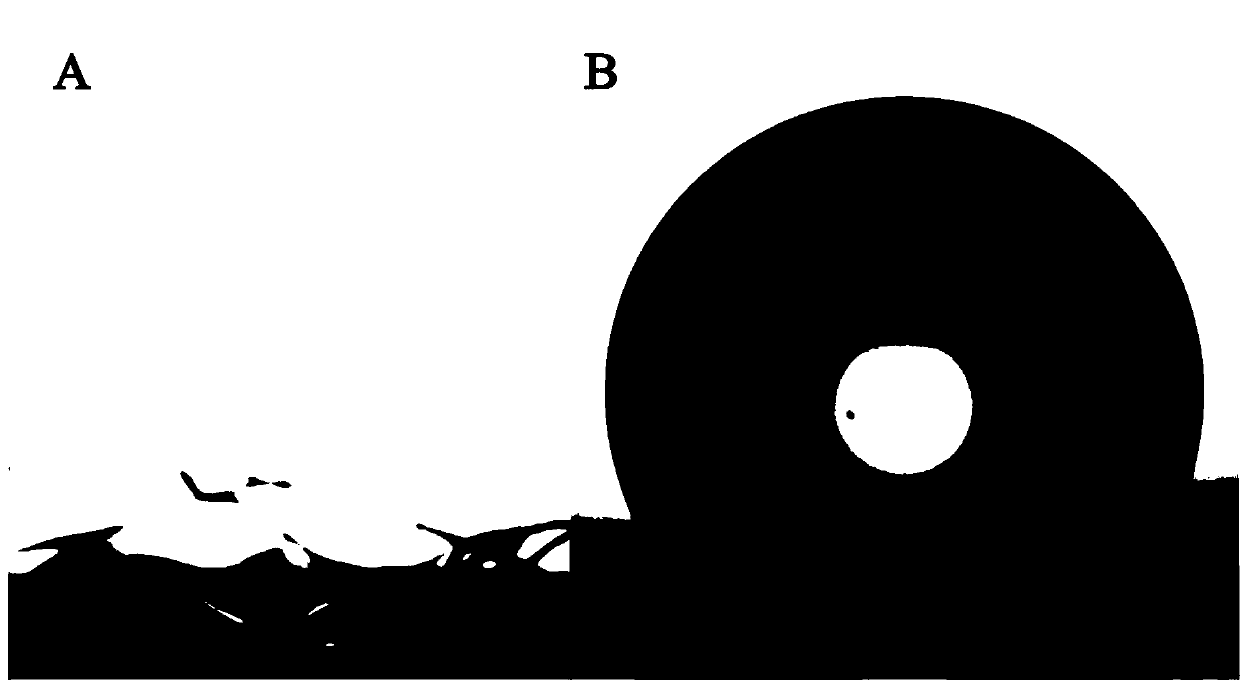

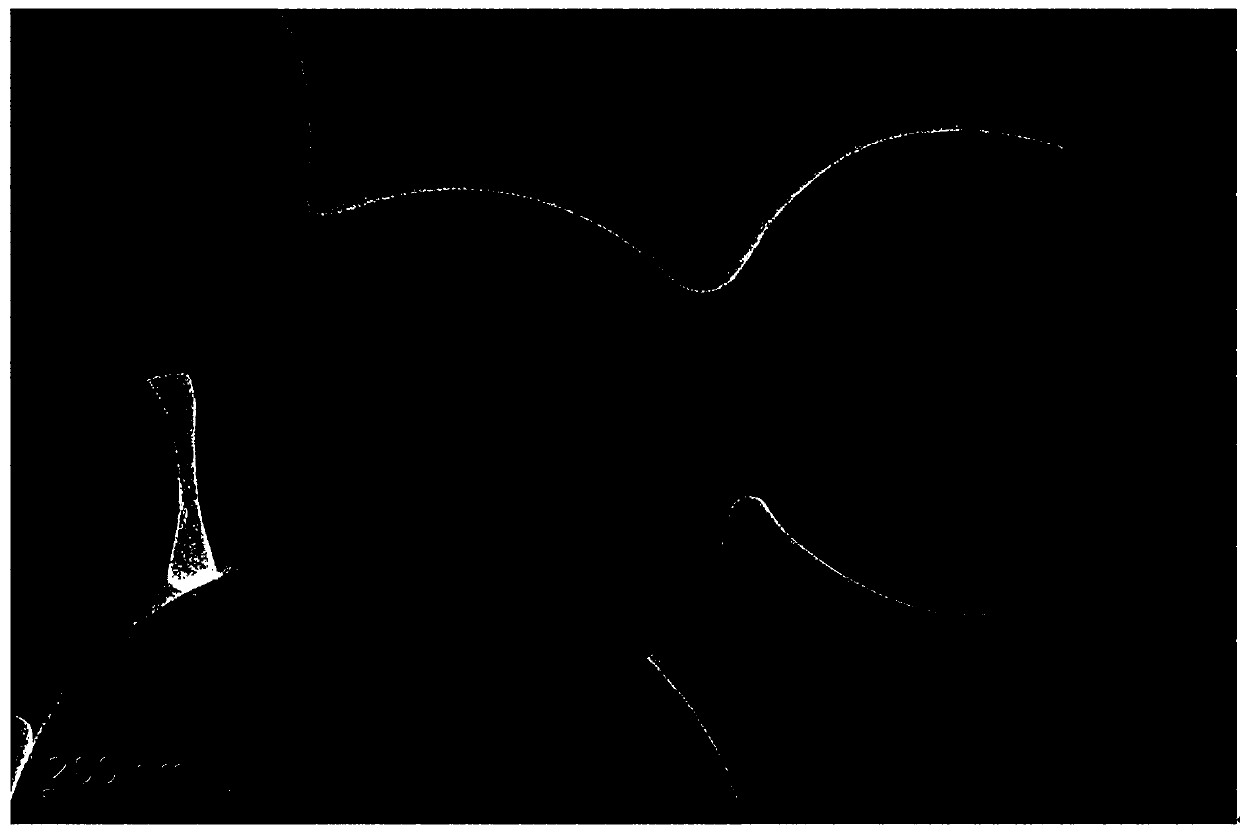

Image

Examples

Embodiment 1

[0021] a. Preparation of organosilane polymer coating with high superhydrophobicity

[0022] Two organosilanes, TEOS and HDTMS, were dissolved in EtOH and NH 3 -EtOH mixed solvent, stirred for 0.5 hour to make the mixture uniform. After the reaction at 80°C, filter with suction and dry to obtain the organosilane polymer; then add 40 mg of the organosilane polymer into 10 mL of anhydrous EtOH, and ultrasonically dissolve for 10 minutes, so that the organosilane polymer is uniformly dispersed in anhydrous EtOH Among them, the organosilane polymer coating with higher superhydrophobicity was obtained.

[0023] b. Preparation of superhydrophobic coating materials

[0024] Felt was used as the coating base material, and 40 mg of organosilane polymer was added into 10 mL of anhydrous EtOH, and ultrasonically dissolved for 10 minutes, so that the organosilane polymer was uniformly dispersed in anhydrous EtOH. When the curing temperature was 80 °C, the obtained Highly superhydrophob...

Embodiment 2

[0026] a. Preparation of organosilane polymer coating with high superhydrophobicity

[0027] Two organosilanes, TEOS and HDTMS, were dissolved in EtOH and NH 3 -EtOH mixed solvent, stirred for 0.5 hour to make the mixture uniform. After the reaction at 80°C, filter with suction and dry to obtain the organosilane polymer; then add 40 mg of the organosilane polymer into 10 mL of anhydrous EtOH, and ultrasonically dissolve for 10 minutes, so that the organosilane polymer is uniformly dispersed in anhydrous EtOH Among them, the organosilane polymer coating with higher superhydrophobicity was obtained.

[0028] b. Preparation of hydrophobic coating material

[0029] Felt was used as the coating base material, and 40 mg of organosilane polymer was added into 10 mL of anhydrous EtOH, and ultrasonically dissolved for 10 minutes, so that the organosilane polymer was uniformly dispersed in anhydrous EtOH. When the curing temperature was 20 °C, a hydrophobic organosilane polymer coati...

Embodiment 3

[0031] a. Preparation of organosilane polymer coating with higher superhydrophobicity:

[0032] Two organosilanes, TEOS and HDTMS, were dissolved in EtOH and NH 3 -EtOH mixed solvent, stirred for 0.5 hour to make the mixture uniform. After the reaction at 80°C, filter with suction and dry to obtain the organosilane polymer; then add 40 mg of the organosilane polymer into 10 mL of anhydrous EtOH, and ultrasonically dissolve for 10 minutes, so that the organosilane polymer is uniformly dispersed in anhydrous EtOH Among them, the organosilane polymer coating with higher superhydrophobicity was obtained.

[0033] b. Preparation of hydrophobic coating material:

[0034]Felt was used as the coating base material, and 40 mg of organosilane polymer was added into 10 mL of anhydrous EtOH, and ultrasonically dissolved for 10 minutes, so that the organosilane polymer was uniformly dispersed in anhydrous EtOH. When the curing temperature was 40 °C, a hydrophobic organosilane polymer co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap