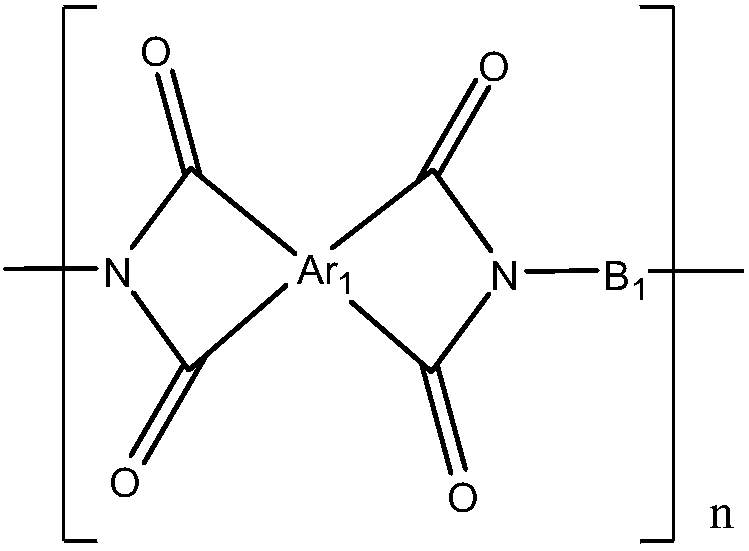

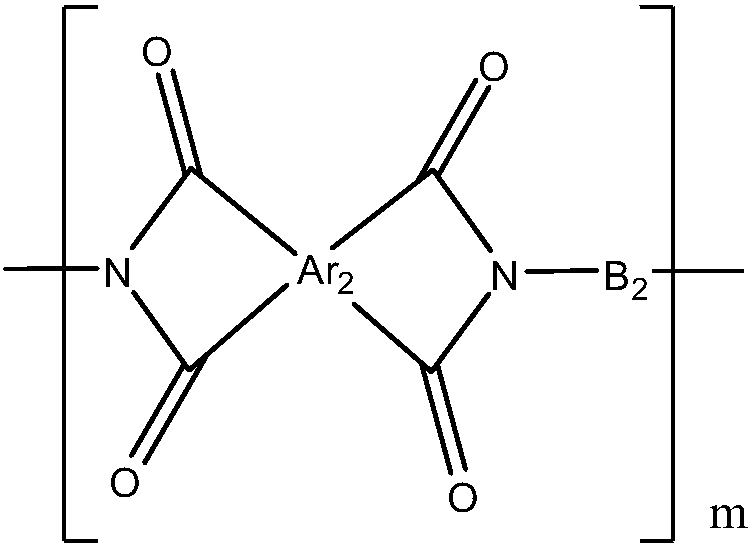

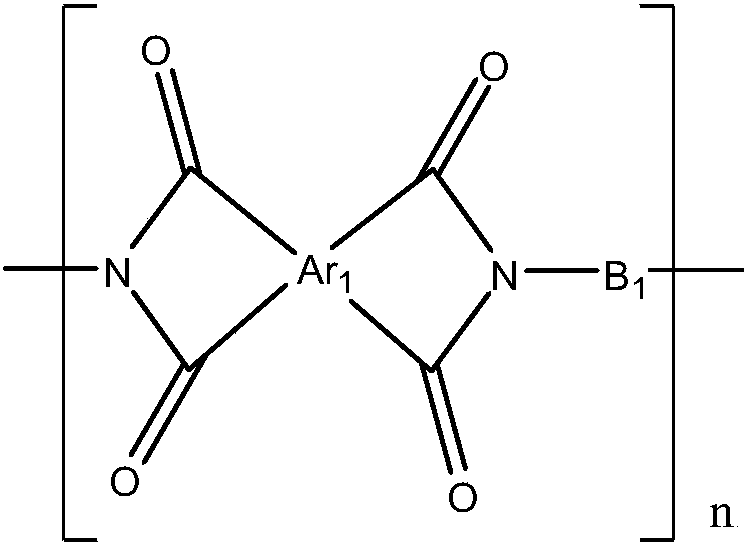

Thermoplasticity polyimide compound with low modulus and high cementitiousness and application and preparation method thereof

A polyimide, polyimide layer technology, applied in chemical instruments and methods, adhesive types, conjugated diene adhesives, etc., can solve the problem of lower glass transition temperature and poor dimensional stability , double-sided flexible copper clad laminate heat resistance, solder resistance and other issues, to achieve the effect of improving adhesion, good compatibility, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Under a nitrogen atmosphere, add 45.00 g of 2,2-bis[4-(4-aminophenoxy)phenyl]propane into 500 g of NMP solvent, stir until completely dissolved; then add 45.64 g of bis Phenol A type diether dianhydride and 6.45g of 3,3',4,4'-BPDA, then stirred for about 4h; then added 19.42g of nano-core-shell polymer, and then continued to stir for 20h to prepare thermoplastic polyimide The precursor solution of the amine composition has a solid content of 18.9 wt % and a viscosity of 6500 mPa·s. The added nano-core-shell polymer has a particle size of 100nm, the core is polybutadiene rubber, and the shell is a polymer obtained by copolymerization of styrene and styrene covalently linked to aliphatic amine end groups on the benzene ring, core and shell The weight ratio of m (core): m (shell) = 80:20.

Embodiment 2

[0062] Under nitrogen atmosphere, add 52.49g of 2,2-bis[4-(4-aminophenoxy)phenyl]propane into 500g of NMP solvent, stir until completely dissolved; then add 25.29g of bis Phenol A type diether dianhydride and 29.30g of 4,4'-terephthalic dioxydiphthalic anhydride, then stirred for about 4h; then added 21.41g of nano-core-shell polymer, and then continued to stir for 20h to prepare The precursor solution of the thermoplastic polyimide composition has a solid content of 20.4wt% and a viscosity of 5570mPa·s. The added nano-core-shell polymer has a particle size of 100nm, the core is polybutadiene rubber, and the shell is a polymer obtained by copolymerization of styrene and styrene covalently linked to aliphatic amine end groups on the benzene ring, core and shell The weight ratio of m (core): m (shell) = 60:40.

Embodiment 3

[0064] Under nitrogen atmosphere, add 40.54g of 2,2-bis[4-(4-aminophenoxy)phenyl]propane and 13.18g of 3,4'-ODA into 500g of NMP solvent, stir until completely dissolved ; Add 83.10g of bisphenol A type diether dianhydride in three batches, then stir for about 4h; add 54.73g of nano-core-shell polymer, and then continue to stir for 20h to prepare the thermoplastic polyimide composition. Body solution, its solid content is 27.7wt%, viscosity is 8400mPa·s. Added nano-core-shell polymer, the particle size is 200nm, the core is styrene-butadiene rubber, the shell is a polymer obtained by copolymerization of styrene and styrene covalently connected to the terminal group of aliphatic amine on the benzene ring, the weight of the core and the shell layer The ratio is m (core): m (shell) = 80:20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com