Method for making suaeda salsa beverage through ultrasonic wave assisted enzyme method

A technology of ultrasonic and auxiliary enzymes, applied in the direction of ultrasonic treatment of food, function of food ingredients, food ingredients containing natural extracts, etc., can solve the problems of vitamin material stability damage, unfavorable to health, etc., to reduce adverse effects and easy to control. and maintenance, the effect of reducing the extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

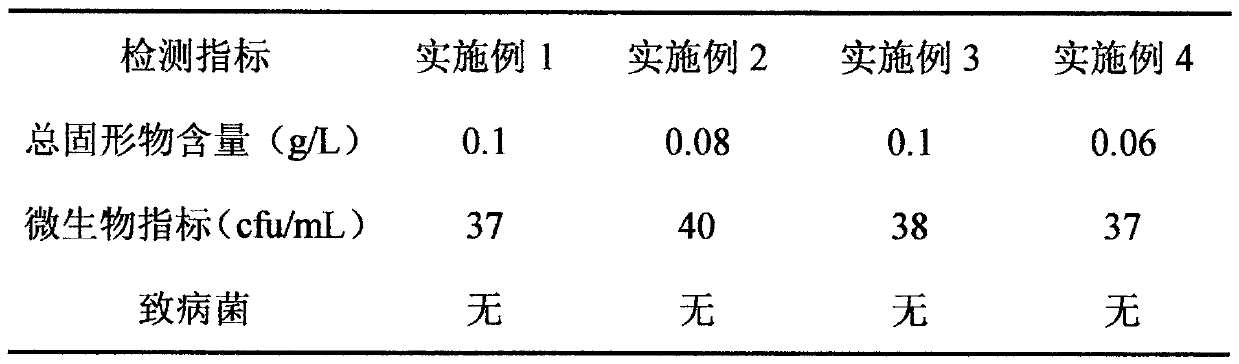

Embodiment 1

[0047] (1) Collect fresh leaves of Suaeda salsa, wash once, dry at 30°C, pulverize, and pass through a 20-mesh sieve for later use;

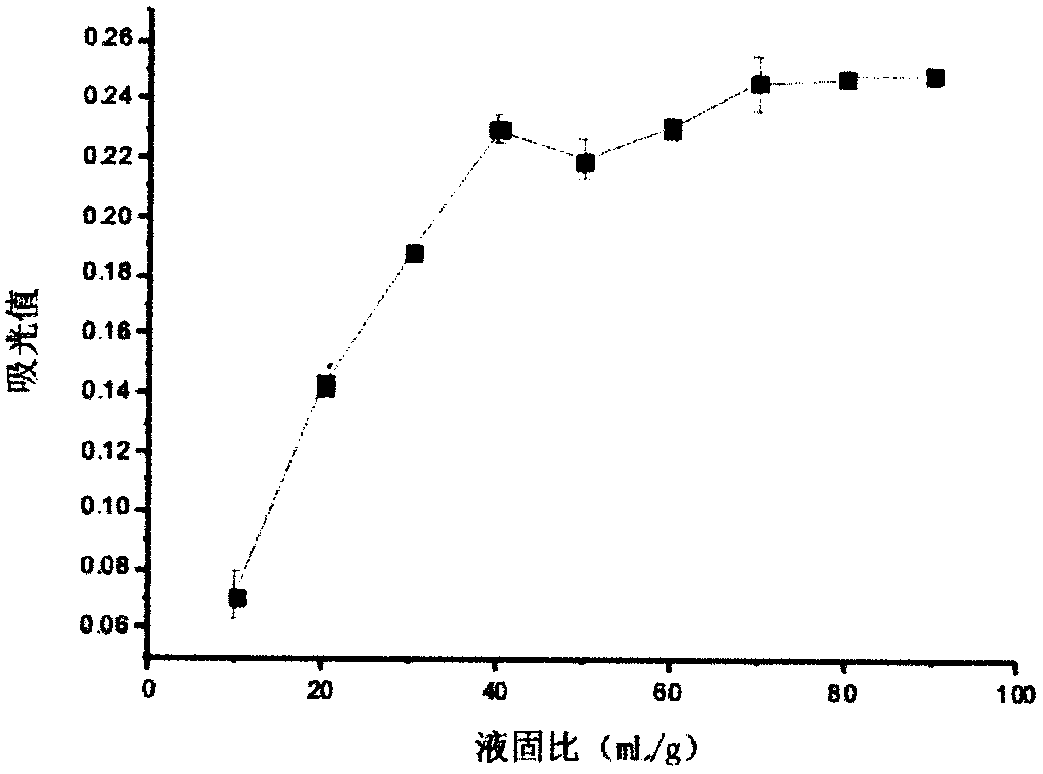

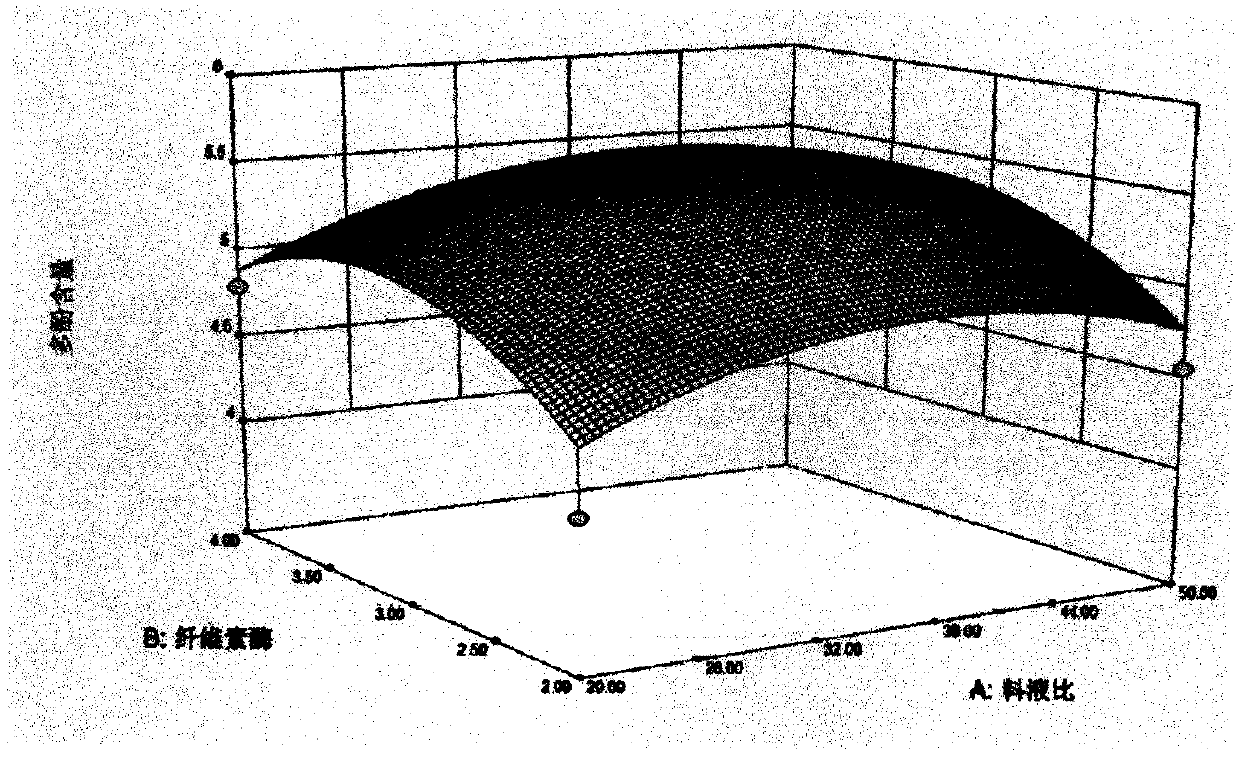

[0048] (2) Add deionized water according to the mass ratio of material to liquid 1:20, add 2% (w / w) cellulase, add 0.05% vitamin C, enzymolysis time 20min, enzymolysis temperature 35 ℃, ultrasonic power 50w, extract The number of times is 2 times, and the leaching solution combined twice is filtered through a mechanical filter, an adsorption filter, and a security filter in sequence;

[0049] (3) Then use a hollow fiber membrane with a diameter of 0.001 μm to inject into the air-water mixer by ultrafiltration, the liquid inlet rate is 900L / h, the pressure is 0.045Mpa, the feed liquid concentration is 200μg / L, the ultrafiltration time is 200min, and the backwash cycle is 20min. The backwashing time is 40s, and the method of running up for 20 minutes and backwashing up for 40s is adopted, and the filtrate is aseptically filled.

Embodiment 2

[0051] (1) Collect fresh leaves of Suaeda salsa, wash them twice, dry them at 40°C, crush them, and pass them through a 30-mesh sieve for later use;

[0052] (2) Add deionized water according to the mass ratio of material to liquid 1:30, add 2.5% (w / w) cellulase, add 0.06% vitamin C, enzymolysis time 25min, enzymolysis temperature 40 ℃, ultrasonic power 100w, extract The number of times is 2 times, and the leaching solution combined twice is filtered through a mechanical filter, an adsorption filter, and a security filter in sequence;

[0053] (3) Then use a hollow fiber membrane with a diameter of 0.004 μm to inject into the air-water mixer by ultrafiltration, the liquid inlet rate is 1100L / h, the pressure is 0.06Mpa, the feed liquid concentration is 300μg / L, the ultrafiltration time is 200min, and the backwash cycle is 30min. The backwashing time is 60s, and the method of running up for 30min and backwashing up for 60s is adopted, and the filtrate is aseptically filled.

Embodiment 3

[0055] (1) Collect fresh leaves of Suaeda salsa, wash them three times, dry them at 40°C, crush them, and pass them through a 30-mesh sieve for later use;

[0056] (2) Add deionized water according to the mass ratio of material to liquid 1:40, add 4% (w / w) cellulase, add 0.07% vitamin C, enzymolysis time 30min, enzymolysis temperature 45 ℃, ultrasonic power 150w, extract The number of times is 2 times, and the leaching solution combined twice is filtered through a mechanical filter, an adsorption filter, and a security filter in sequence;

[0057] (3) Then use a hollow fiber membrane with a diameter of 0.007 μm to inject into the air-water mixer by ultrafiltration, the liquid inlet rate is 1300L / h, the pressure is 0.1Mpa, the feed liquid concentration is 300μg / L, the ultrafiltration time is 200min, and the backwash cycle is 20min. The backwashing time is 60s, and the method of running up for 20 minutes and backwashing down for 60s is adopted, and the filtrate is aseptically fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com