Tissue engineered cornea

A tissue engineering, corneal technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problem of reduced expression, and achieve the effect of improving thickness and mechanical toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further illustrated and described below through specific embodiments in conjunction with the accompanying drawings.

[0030] The ultra-thin amniotic membrane in the following examples is the dense layer retained after the spongy layer and reticular layer are removed by protease digestion.

[0031] Materials and methods:

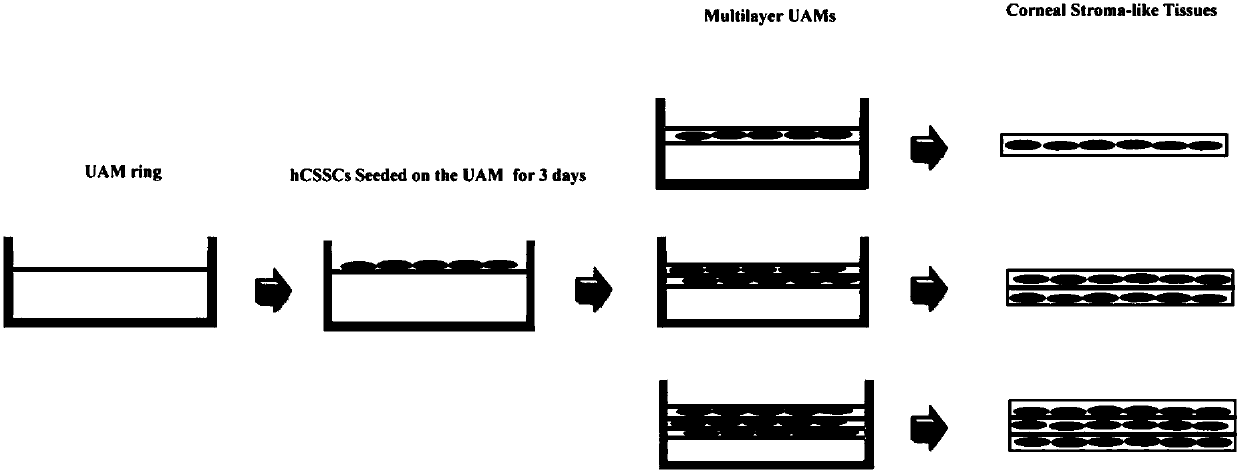

[0032] 1. Multi-layer ultra-thin amniotic membrane production process (such as figure 1 shown)

[0033] (1) The placenta comes from a cesarean section patient, with the consent of the puerpera and her family members and signed a consent form, and the test for AIDS, syphilis, hepatitis B, hepatitis C and other pathogens before the cesarean section is negative; in the ultra-clean workbench, the Cut the amniotic membrane with chorion from the placenta; tear off the chorion; rinse repeatedly with sterile PBS solution until the amniotic membrane is smooth and transparent without blood stains to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com