Application of a green activator in the preparation of porous carbon materials

An activator and porous carbon technology, which is applied in the application field of green activators in the preparation of porous carbon materials, can solve the problems of corroded instruments, high price, high risk factor, etc., and achieve excellent product performance, simple process, and huge economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

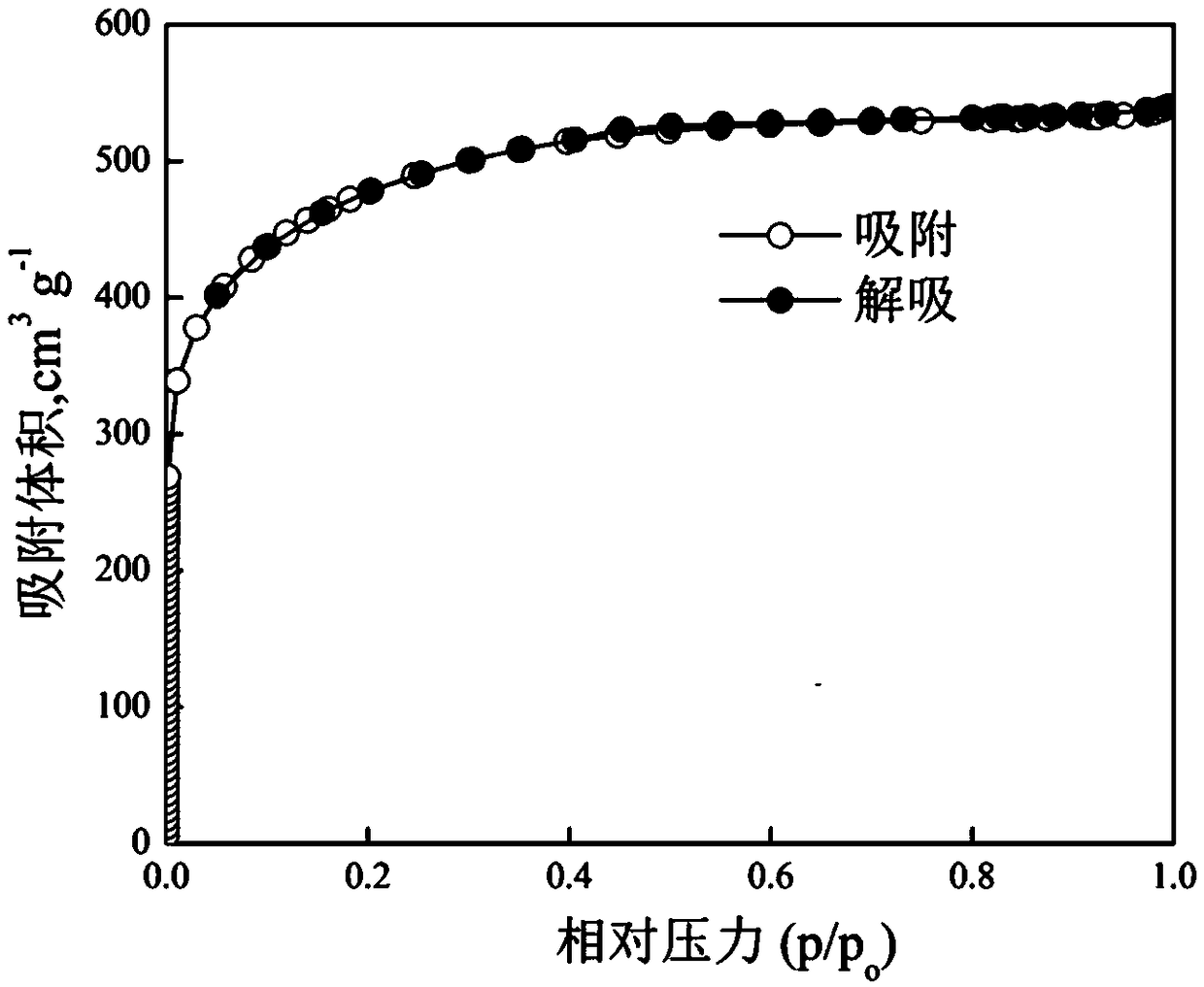

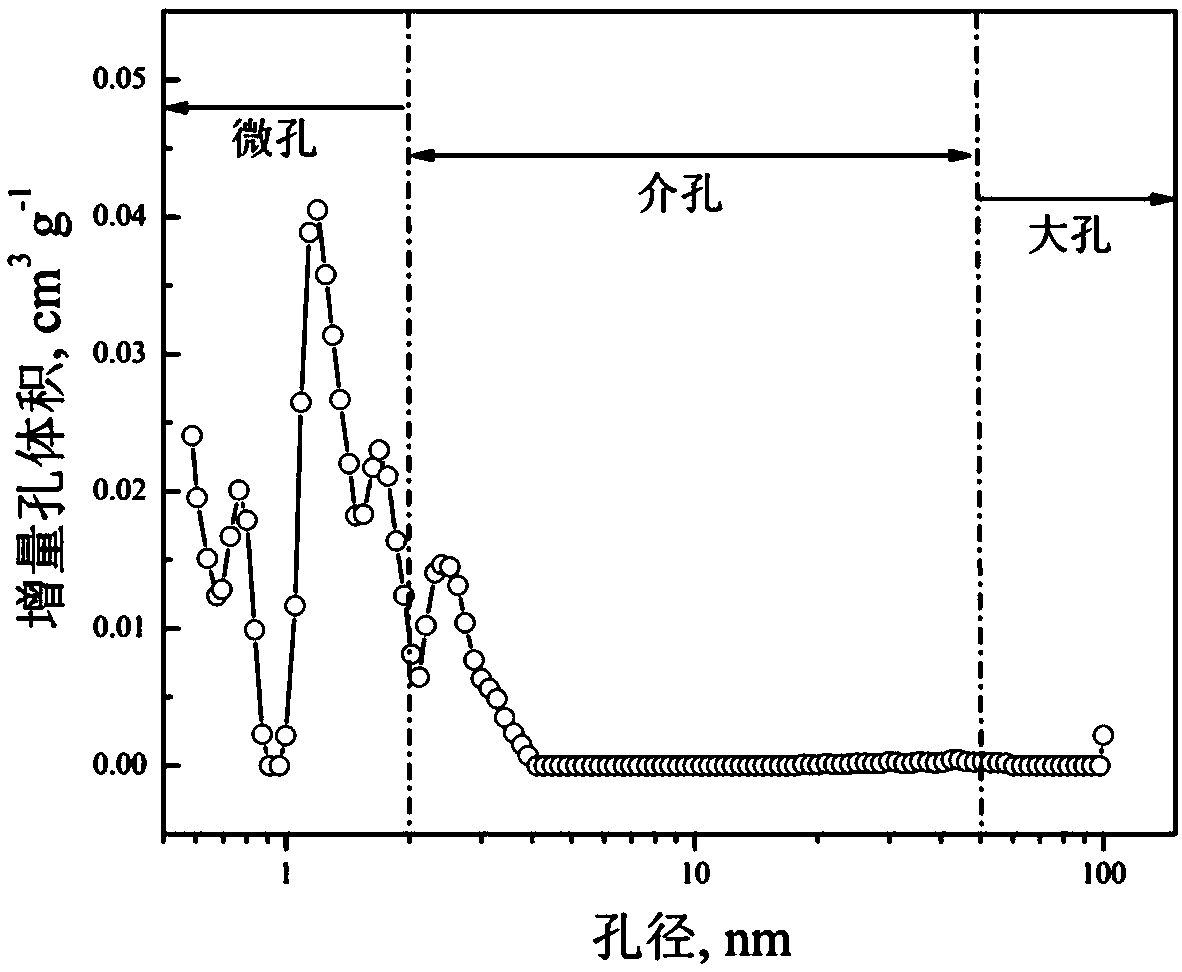

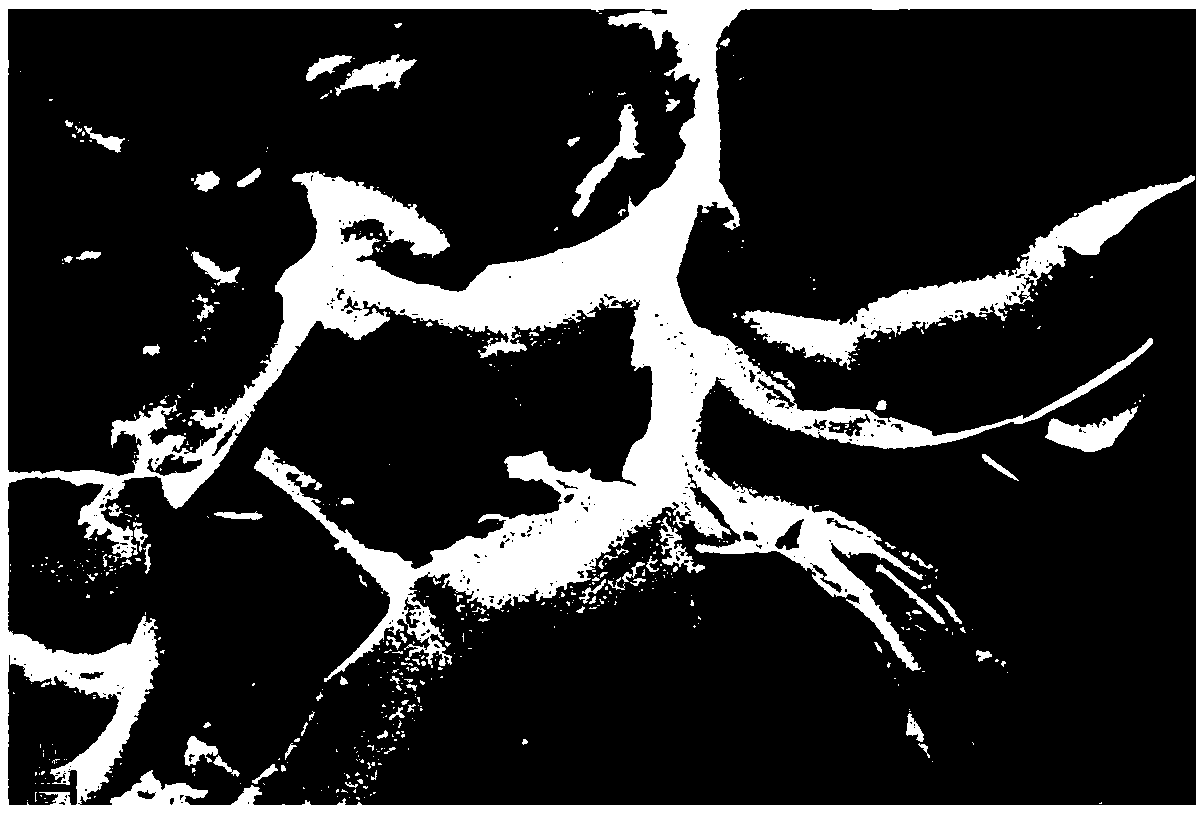

[0017] In this example, cotton stalks were selected as the carbon precursor. Weigh 16 g of straw powder into 50 mL of deionized water, put it into a hydrothermal reactor, and perform hydrothermal treatment at 250 °C for 4 h. After cooling, wash with deionized water, and filter with suction to obtain a brown solid residue (hydrothermal charcoal). According to the mass ratio of hydrothermal charcoal: potassium formate = 1:4, it was dissolved in ultrapure water, stirred with magnetic ions at 70°C for 4 hours, and dried at 120°C. Put it into a square corundum crucible, put it in a tubular muffle furnace, set the nitrogen flow rate at 400 mL / min, heat it to 850°C at 5°C / min, and keep it for 1h, then cool it down to room temperature at 5°C / min, take it out The crucible, the black solid residue was washed with 10vol.% hydrochloric acid at 70°C and deionized water successively, filtered with suction and dried in an oven at 120°C overnight. Finally, it was pulverized with an agate mo...

Embodiment 2

[0019] In this example, cotton stalks were selected as the carbon precursor. Weigh 16 g of straw powder into 50 mL of deionized water, put it into a hydrothermal reactor, and perform hydrothermal treatment at 250 °C for 4 h. After cooling, wash with deionized water, and filter with suction to obtain a brown solid residue (hydrothermal charcoal). According to the mass ratio of hydrothermal charcoal: potassium formate = 1:4, it was dissolved in ultrapure water, stirred with magnetic ions at 70°C for 4 hours, and dried at 120°C. Put it into a square corundum crucible, put it in a tubular muffle furnace, set the nitrogen flow rate at 50 mL / min, heat it at 5°C / min to 850°C, and keep it for 1h, then cool it down to room temperature at 5°C / min, take it out The crucible, the black solid residue was washed with 10vol.% hydrochloric acid at 70°C and deionized water successively, filtered with suction and dried in an oven at 120°C overnight. Finally, it was pulverized with an agate mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com