Sewage denitrification treatment system

A treatment system and denitrification technology, applied in the field of sewage treatment, can solve the problems such as the inability to take into account the uniformity of carbon sources used by microorganisms, the protection of the filter structure, the lack of a structure for adding carbon sources, and the blocking of filter layer gaps. The effect of saving carbon source, saving energy and moderate denitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

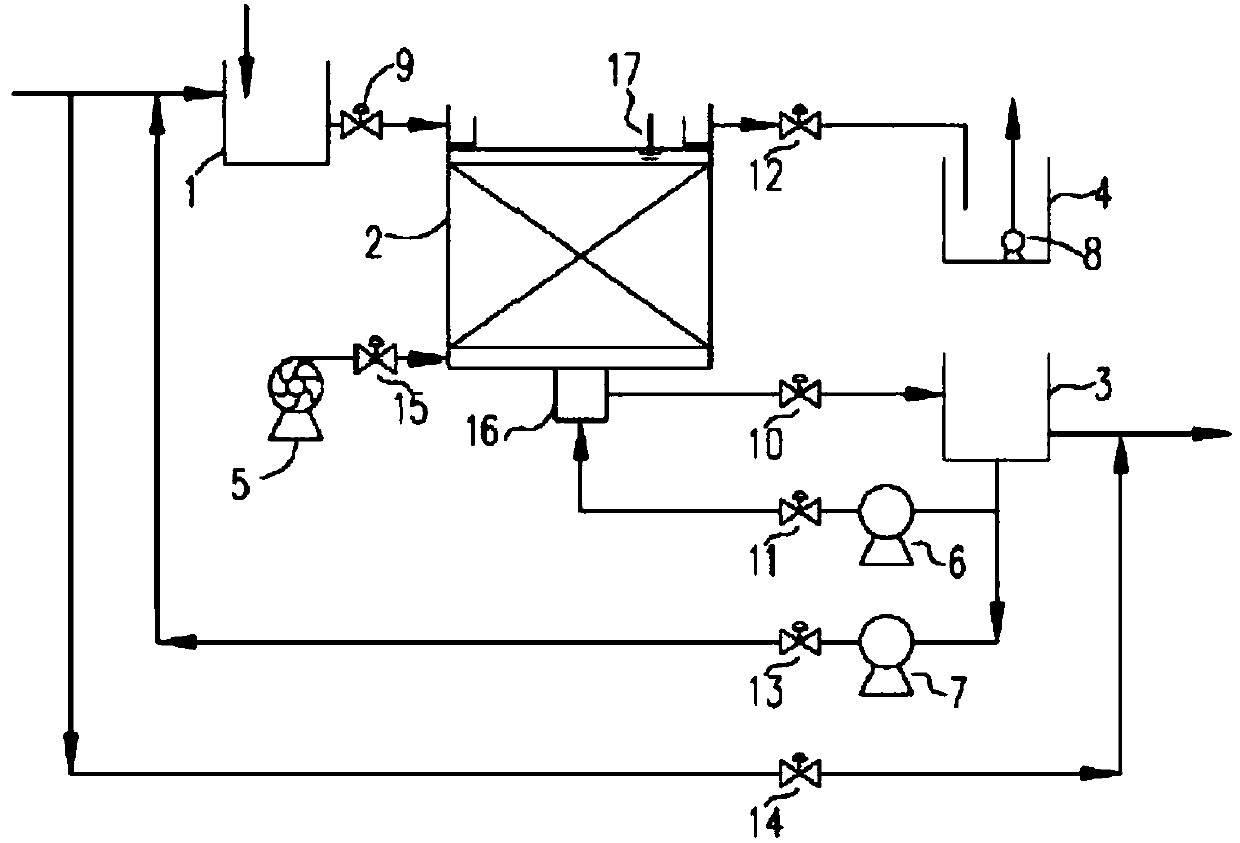

[0031] Such as figure 1 As shown, a kind of sewage denitrification treatment system of the present invention comprises denitrification deep bed filter tank 2, reflux system, backwash system, clear water tank 3, sewage tank 4, carbon source mixing tank 1, surpassing system, and PLC control system.

[0032] The denitrification deep bed filter 2 is composed of a quartz sand filter layer, a supporting layer and an air-water distribution layer from top to bottom, and the bottom of the air-water distribution layer is provided with a water collection tank 16; Count 17 and the distribution channel, and the weir plate is arranged around the distribution channel.

[0033] The clean water pool 3 and the sewage pool 4 are located on the water outlet side of the denitrification deep bed filter 2, and the water collection tank 16 is connected to the clean water pool 3 through the water outlet regulating valve; Connect the sewage tank 4. The filtered sewage flows into the sewage tank 4, a...

Embodiment 2

[0042] The filtering process of the mechanism in embodiment 1 is as follows:

[0043] Carbon source mixing process:

[0044] The sewage enters the carbon source mixing pool 1, and mixes the carbon source into the carbon source mixing pool 1. The agitator stirs the carbon source mixing pool 1. After the sewage and the carbon source are fully mixed, under the action of gravity, the mixed sewage flows into the denitrification deep bed filter 2 upper part of the water distribution tank or distribution channel, and overflow from the weir plate around the water distribution tank or distribution channel, and evenly distribute water to the denitrification deep bed filter 2; carbon source dosage is based on the influent NO 3 NO monitored by -N analyzer 3 -N content and effluent NO 3 -N analyzer feedback data determined.

[0045] Filtration and denitrification process of denitrification deep bed filter 2:

[0046] Sewage passes through the quartz sand filter layer, support layer, a...

Embodiment 3

[0060] On the basis of the structure of Embodiment 1, only the return system can be provided, and no overtaking system can be provided.

[0061] The following parameters can be used: system inlet NO 3 -N concentration 45mg / L, effluent NO 3 -N concentration is 8mg / L, denitrification filter influent NO 3 -N concentration 25mg / L, effluent NO 3 -N concentration 8mg / L, the excess water volume is 0, the return flow is 80% of the denitrification filter water output, and the total nitrogen removal rate of the system is 82.2%; the denitrification deep bed filter 2 quartz sand filter layer height is 2.44m, The particle size is 2-3mm, and the thickness of the supporting layer is 0.38mm-38mm; the denitrification deep bed filter 2 nitrogen flooding time interval is 2h; the backwashing cycle is 12h, air washing is 5min, air-water combined flushing is 12min, and water washing is 5min alone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com