A kind of preparation method of 3-thiophene formaldehyde

A technology of thiophene formaldehyde and tetramethoxypropane, applied in the direction of organic chemistry and the like, can solve the problems of low reagent safety, low reaction temperature, difficult to enlarge, etc., and achieves saving operating cost and energy consumption, high yield, and reduction of raw materials. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of 3-thiophenecarbaldehyde of the present invention, comprises the steps:

[0040] (a) Adding acid to 1,1,3,3-tetramethoxypropane under stirring conditions, controlling the reaction temperature to 20-40°C, and stirring for 2-3 hours;

[0041] (b) adding 1,4-dithio-2,5-diol and a base to the mixture obtained in step (a), controlling the reaction temperature to 50-70° C., and reacting for 4-6 hours to obtain a 3-thiophene formaldehyde solution;

[0042] (c) Post-treat the 3-thiophene formaldehyde solution to obtain 3-thiophene formaldehyde; specifically, add the 3-thiophene formaldehyde solution into water to quench, then add an organic solvent to extract and separate the organic phase, wash the organic phase with water, and concentrate to obtain the obtained 3-thiophenecarbaldehyde.

[0043] Wherein, the molar ratio of the 1,4-dithio-2,5-diol, 1,1,3,3-tetramethoxypropane, acid and base is preferably 1:(2-4):(0.2 -0.4): (0.5-1). Within this ratio...

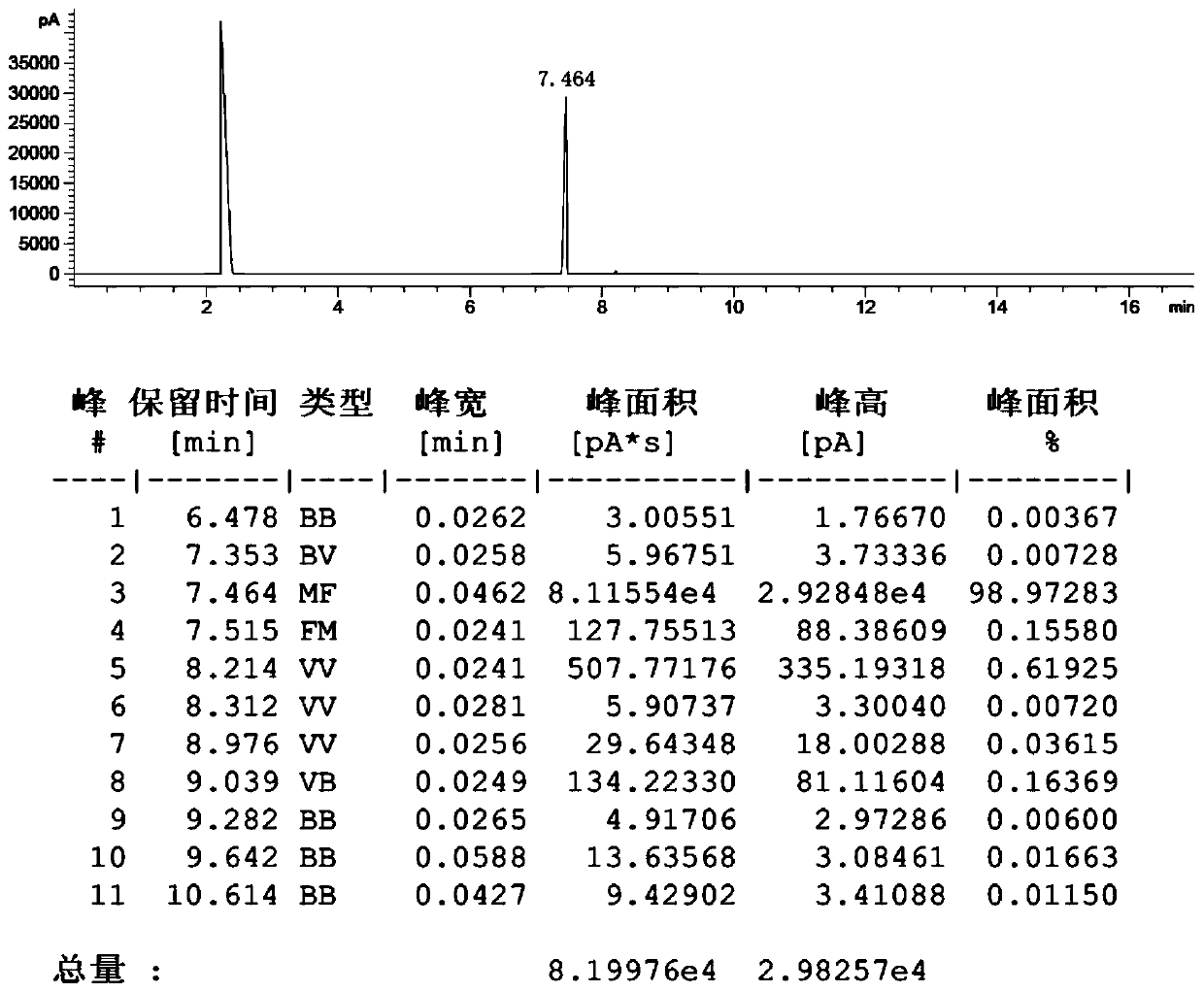

Embodiment 1

[0051] The preparation method of the 3-thiophenecarbaldehyde of present embodiment, comprises the steps:

[0052] (a) Add 2mol of 1,1,3,3-tetramethoxypropane to the reaction vessel at room temperature, and add 0.2mol of hydrochloric acid with a mass fraction of 10% under stirring conditions (0.2mol refers to the addition of hydrochloric acid The amount of HCl, the following examples are the same), the reaction temperature is controlled at 20°C, and the reaction is stirred for 2h.

[0053] (b) Add 1 mol of 1,4-dithio-2,5-diol and 0.5 mol of triethylamine to the mixture in the reaction vessel in step (a), control the reaction temperature to 60°C, and stir for 4 hours , to obtain 3-thiophene formaldehyde solution.

[0054] (c) Add the 3-thiophene formaldehyde solution obtained in step (b) dropwise to cold water at 5°C to quench, after the dropwise addition, add ethyl acetate to the system for extraction and phase separation, and collect the organic phase; Add water to wash with...

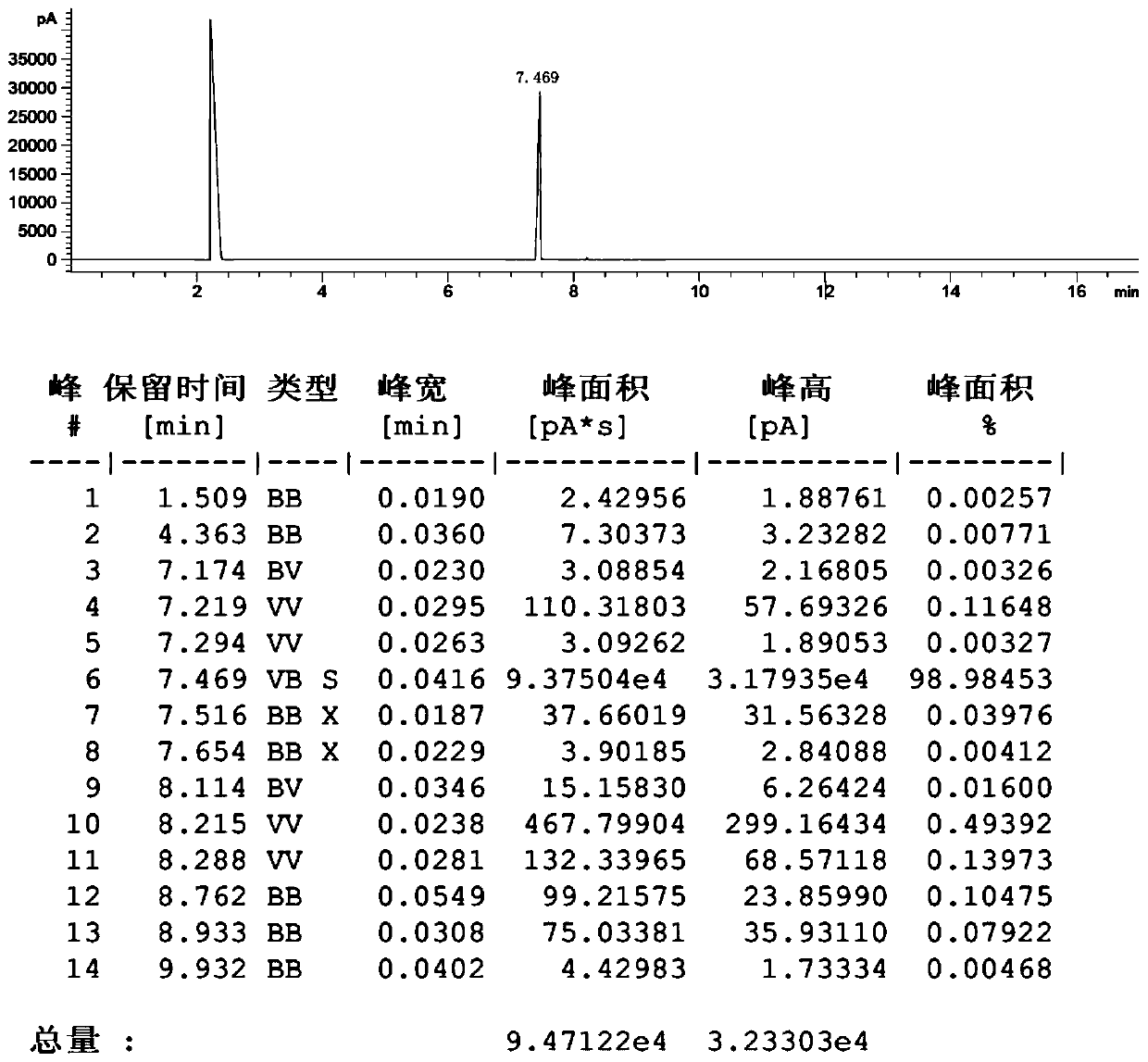

Embodiment 2

[0056] The preparation method of the 3-thiophenecarbaldehyde of present embodiment, comprises the steps:

[0057] (a) Add 3 mol of 1,1,3,3-tetramethoxypropane to the reaction vessel at room temperature, add 0.2 mol of hydrochloric acid with a mass fraction of 8% under stirring conditions, control the reaction temperature at 25°C, and stir Reaction 3h.

[0058] (b) Add 1 mol of 1,4-dithio-2,5-diol and 0.7 mol of diethylamine to the mixture in the reaction vessel in step (a), control the reaction temperature to 70°C, and stir for 4 hours , to obtain 3-thiophene formaldehyde solution.

[0059] (c) Add the 3-thiophene formaldehyde solution obtained in step (b) dropwise to cold water at 10°C for quenching. After the dropwise addition, add toluene to the system for extraction and phase separation, and collect the organic phase; add to the organic phase wash with water, and then separate phases to collect the organic phase; concentrate the organic phase to remove excess raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com