High density fermentation method of glucose oxidase in pichia pastoris

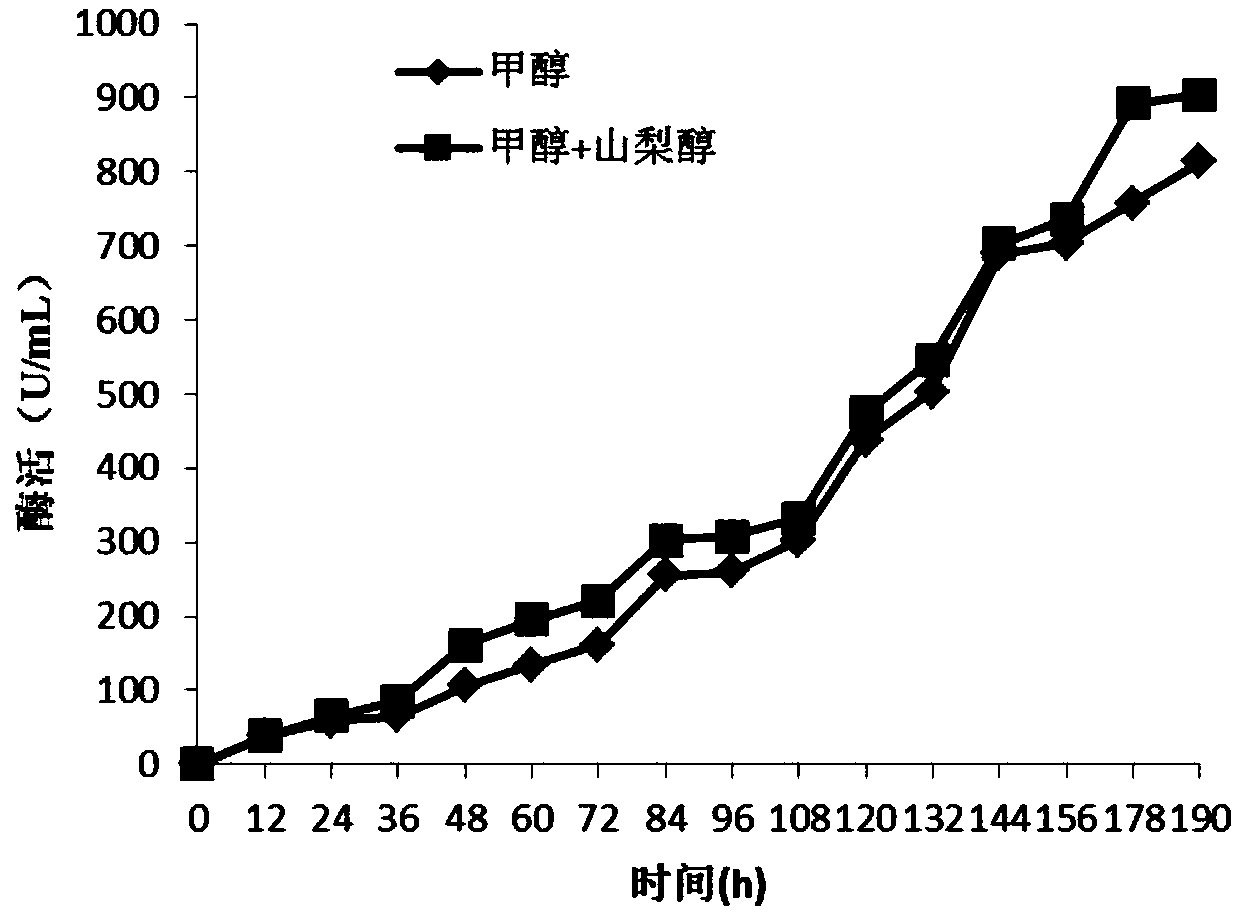

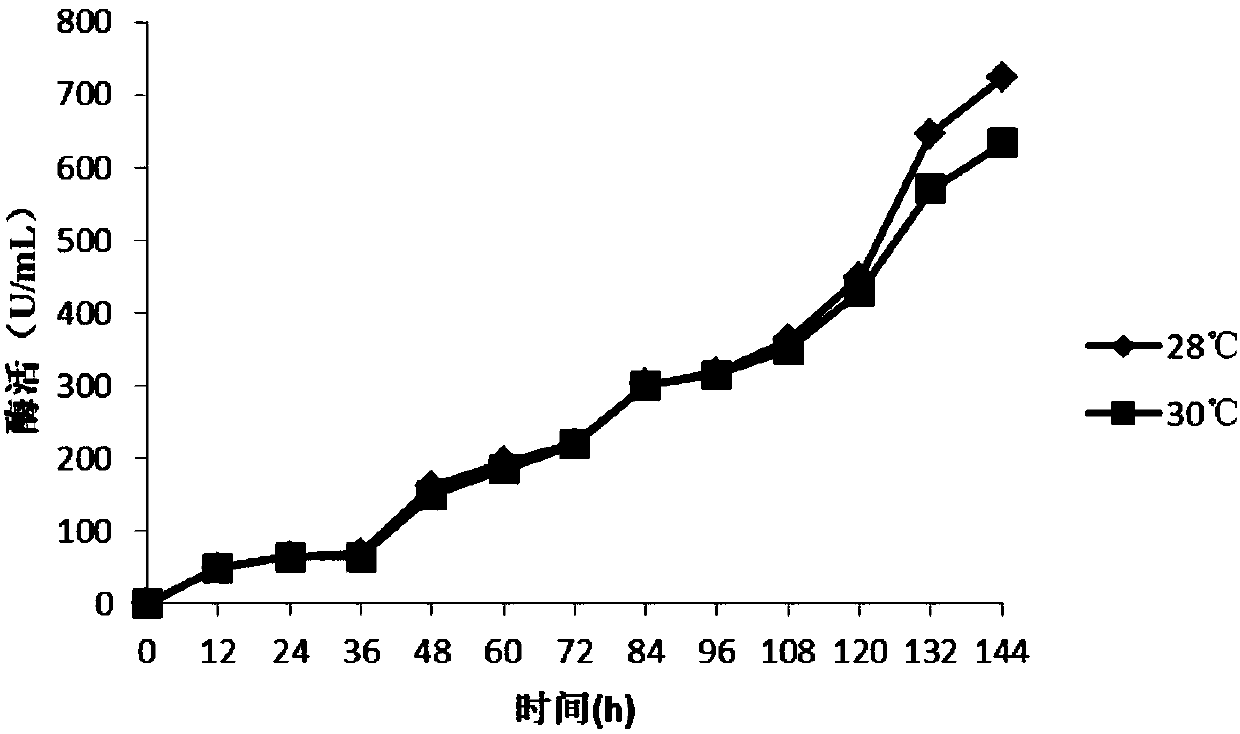

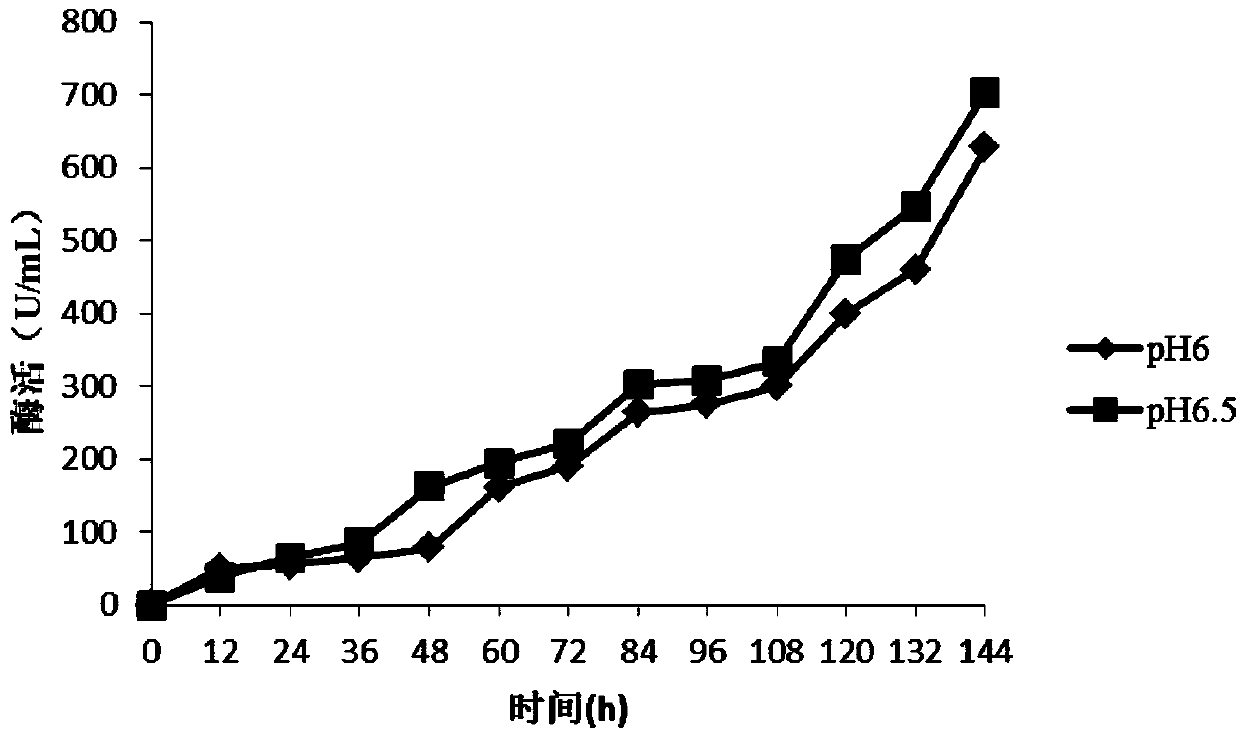

A technology of glucose oxidase and high-density fermentation, applied in the field of microbial fermentation, can solve problems such as difficulty in purification, and achieve the effects of increasing secretion, reducing dosage and increasing GOD yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The strain was inoculated into the seed solution of the primary test tube of 3mL YPD medium according to the inoculum amount of 3%. After culturing for 12h at 30°C and 250 rpm, the strain was transferred to the shake flask of 500mL of 100mL BMGY secondary seed solution according to the inoculum amount of 3%. , 30°C, 250rpm after 12h culture, culture medium OD 600 To 10, obtain the culture expansion liquid of activated strain.

[0047] Inoculate in the fermentor of 10L by the inoculum of 10% inoculated in the fermentor that the bacterial classification expansion culture fluid of activation is filled, fermentor initially dresses 5.6LBSM medium. The initial fermentation control temperature was 28°C, the pH of the fermented liquid was controlled to be 5.0 with 28% concentrated ammonia water, and the dissolved oxygen on the tank was controlled at 0 by adjusting the stirring speed and ventilation. After the glycerin in the BSM medium is exhausted and the dissolved oxygen ris...

Embodiment 2

[0051] The strain was inoculated into the seed solution of the primary test tube of 3mL YPD medium according to the inoculum amount of 5%. After culturing for 16h at 30°C and 230 rpm, the strain was transferred to the shake flask of 500mL of 100mL BMGY secondary seed solution according to the inoculum amount of 5%. , 30°C, 230rpm cultured for 16h, the culture solution OD 600 To 10, obtain the culture expansion liquid of activated strain.

[0052] The bacterial classification expansion culture liquid of activation is inoculated in the fermentor of 10L by 9% inoculum size, and fermentor initially dresses 5.6LBSM substratum. The initial fermentation control temperature was 28°C, the pH of the fermented liquid was controlled to be 5.0 with 28% concentrated ammonia water, and the dissolved oxygen on the tank was controlled at 0 by adjusting the stirring speed and ventilation. After the glycerin in the BSM medium is exhausted and the dissolved oxygen rises, add 50% (w / v) glycerol c...

Embodiment 3

[0056] The strain was inoculated into the seed solution of the primary test tube of 3mL YPD medium according to the 8% inoculum amount. After culturing for 18 hours at 30°C and 200 rpm, the 8% inoculum amount was transferred to the 500mL 100mL BMGY secondary seed solution shake flask , 30°C, 200rpm after 18h culture, culture solution OD 600 To 10, obtain the culture expansion liquid of activated strain.

[0057] Inoculate in the fermentor of 10L by the inoculum of 10% inoculated in the fermentor that the bacterial classification expansion culture fluid of activation is filled, fermentor initially dresses 5.6LBSM medium. The initial fermentation control temperature was 28°C, the pH of the fermented liquid was controlled to be 5.0 with 28% concentrated ammonia water, and the dissolved oxygen on the tank was controlled at 0 by adjusting the stirring speed and ventilation. After the glycerin in the BSM medium is exhausted and the dissolved oxygen rises, add 50% (w / v) glycerol con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com