Train compartment damping rubber mat and preparation method thereof

A carriage and train technology, applied in the field of train parts, can solve the problems affecting the safe transportation of goods, the small bearing capacity of rubber pads, and uncomfortable riding, so as to improve the utilization channels and utilization value, low cost and good shock absorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

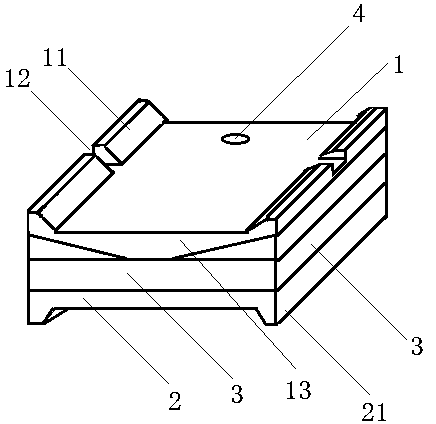

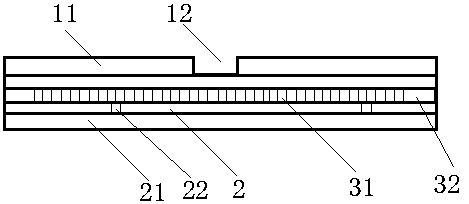

[0019] Such as figure 1 -2 shows a structure of the present invention, a train car damping rubber pad, which is used between the train car and the underframe, and is usually placed at the four corners to reduce the vibration of the car. It includes an upper plate 1 matched with the compartment, a lower plate 2 matched with the underframe and a shock-absorbing layer 3 arranged between the upper plate and the lower plate;

[0020] The upper and lower ends of the upper plate are provided with an upper limit bar 11, which cooperates with the crossbeam on the carriage frame to prevent displacement between the carriage and the shock-absorbing rubber pad, and a limit slot 12 is opened in the middle of the limit bar. Longitudinal fixation can be carried out at the limit slot, usually by screwing a bolt at the position of the beam at the limit slot, which can prevent the shock-absorbing rubber pad from moving in series relative to the length of the beam. The lower side of the upper pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com