Chlortetracycline hydrochloride soluble powder and preparation method thereof

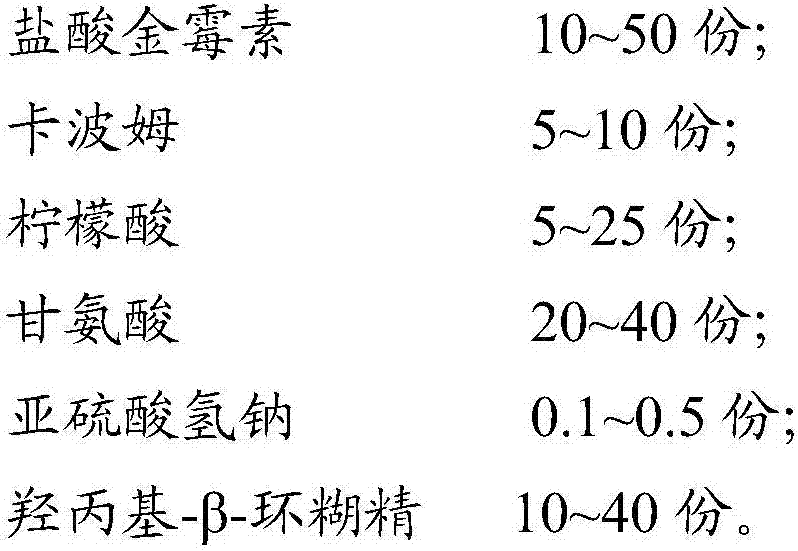

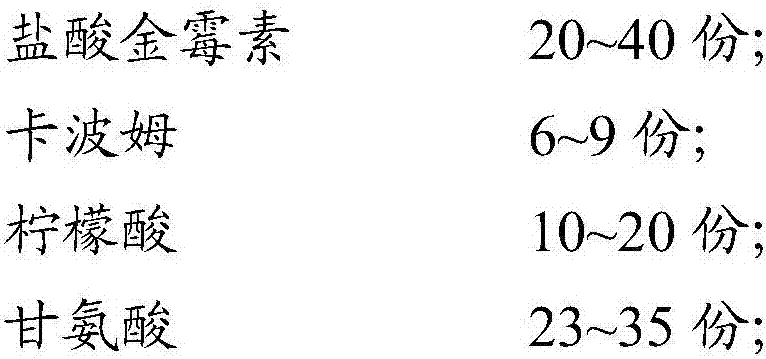

A chlortetracycline hydrochloride, soluble technology, applied in the field of chlortetracycline hydrochloride soluble powder and its preparation, can solve the problems of the influence of preparation stability on the treatment effect, poor long-term stability, increased impurity content and the like, and achieves improved drug bioavailability, The effect of preventing oxidative discoloration and promoting absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides the preparation method of the chlortetracycline hydrochloride soluble powder described in the above technical scheme, comprising the following steps:

[0035] Weighing the raw materials according to the parts by mass, and pulverizing the raw materials respectively;

[0036] mixing the pulverized raw material with water to obtain a raw material aqueous solution;

[0037] The raw material aqueous solution is vacuum freeze-dried and granulated sequentially to obtain aureomycin hydrochloride soluble powder.

[0038] In the present invention, the raw materials are weighed according to the stated parts by mass, and the raw materials are respectively pulverized. In the present invention, the particle size of the pulverized raw material is preferably 60-100 mesh, more preferably 80-100 mesh.

[0039] After the pulverized raw material is obtained, the present invention mixes the pulverized raw material with water to obtain a raw material aqu...

Embodiment 1

[0049] A chlortetracycline hydrochloride soluble powder is made from the following raw materials in weight ratio: carbomer 6kg, glycine 30kg, hydroxypropyl-β-cyclodextrin 30kg, sodium bisulfite 0.3kg, aureomycin hydrochloride 10kg , citric acid 23.7kg.

[0050]The preparation method of the above-mentioned chlortetracycline hydrochloride soluble powder comprises the following steps: weighing each raw material according to weight percentage, pulverizing and sieving the raw materials respectively, to obtain pulverized raw materials with a particle size of 80 mesh. Then, the pulverized carbomer, glycine, hydroxypropyl-β-cyclodextrin, sodium bisulfite, chlortetracycline hydrochloride, and citric acid were sequentially dissolved into the aqueous solution, and the vortex oscillator was used to shake and dissolve for 30 minutes. It is dried by a vacuum freeze dryer and granulated to obtain the final product. The vacuum degree of the vacuum freeze-drying machine is -0.06Pa, the vacuum...

Embodiment 2

[0052] A chlortetracycline hydrochloride soluble powder is made from the following raw materials in weight ratio: carbomer 7kg, glycine 30kg, hydroxypropyl-β-cyclodextrin 25kg, sodium bisulfite 0.3kg, chlortetracycline hydrochloride 20kg , citric acid 17.7kg.

[0053] The preparation method of the chlortetracycline hydrochloride soluble powder includes the following steps: weighing each raw material according to the weight percentage, pulverizing and sieving the raw materials respectively, to obtain the pulverized raw materials with a particle size of 100 mesh. Then, the pulverized carbomer, glycine, hydroxypropyl-β-cyclodextrin, sodium bisulfite, chlortetracycline hydrochloride, and citric acid were sequentially dissolved into the aqueous solution, and the vortex oscillator was used to shake and dissolve for 20 minutes. It is dried by a vacuum freeze dryer and granulated to obtain the final product. The vacuum degree of the vacuum freeze-drying machine is -0.07Pa, the vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com