Composite greenhouse ecological functional bed and method for utilizing composite greenhouse ecological functional bed to conduct sludge amount reduction and ecological disposal

An ecological function, greenhouse technology, applied in biological sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of low sludge treatment efficiency, high sludge moisture content, Long disposal cycle and other problems, to achieve the effect of reducing the total volume of sludge, low sludge moisture content, and high degree of reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

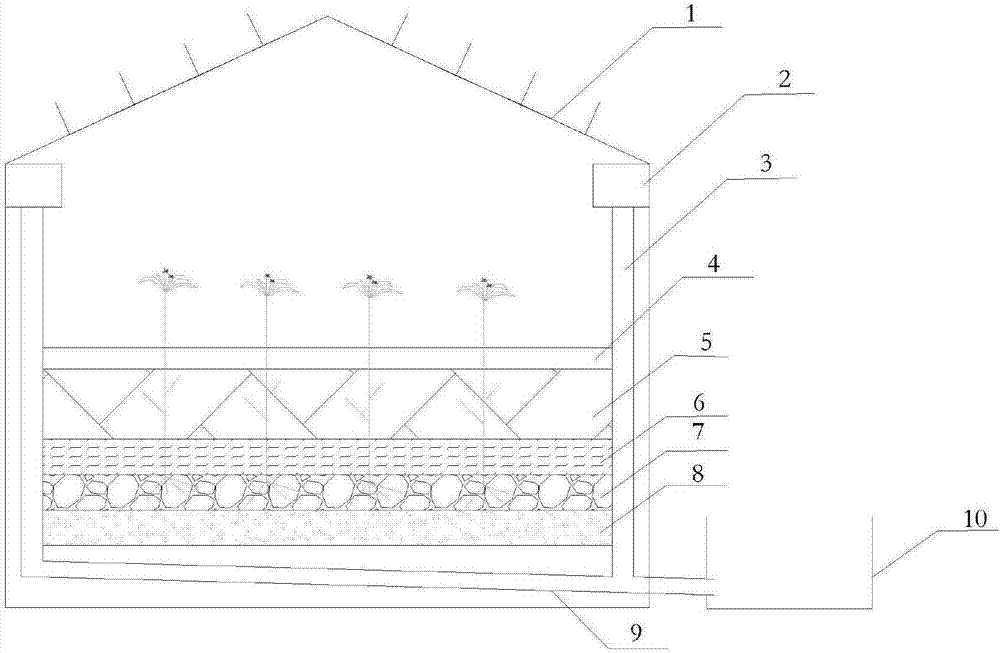

[0022] A composite greenhouse ecological function bed, such as figure 1 Shown, including composite greenhouse and its internal ecological function bed.

[0023] The composite greenhouse is a steel frame structure unit with a length of 5-10m, a width of 3-5m, and a height of 2-3m, and a combination of highly hydrophobic glass 1 with a length of 100-200cm and a width of 50-80cm closed. The highly hydrophobic glass 1 is a layer of 0.5-2 cm nano silicon dioxide hydrophobic material attached to the surface of ordinary glass.

[0024] The bottom of the ecological functional bed is a bed body reinforcement layer, and an anti-seepage film is laid on the bed body reinforcement layer, and a collection and drainage pipe 9 is laid on the top of the anti-seepage film. One end of the collection and drainage pipe 9 is connected to the ventilation pipe, and the other end is connected to the outlet pipe. The ecological function bed is divided into five layers, which are distributed from bott...

Embodiment 2

[0027] A sludge reduction and ecological treatment method, comprising the following steps:

[0028] The sludge with a water content of 98% is pumped into the regulating tank, and then the sludge is intermittently introduced into the composite greenhouse ecological functional bed according to the residence time of the sludge in the functional bed, and the residence time is 30 hours. The composite greenhouse ecological function bed includes the composite greenhouse and its internal ecological function bed. The composite greenhouse is a steel frame structure unit with a length of 5m, a width of 3m, and a height of 2m. The ceiling is 100cm long and 50cm wide. Highly hydrophobic glass with 0.5cm nano-silica hydrophobic material. The bottom of the ecological function bed is a bed reinforcement layer, and an impermeable membrane is laid on the bed reinforcement layer, and a collection and drainage pipe is laid on the impermeability membrane. One end of the collection and drainage pip...

Embodiment 3

[0030] The sludge with a water content of 96% is pumped into the regulating tank, and then the sludge is intermittently introduced into the composite greenhouse ecological functional bed according to the residence time of the sludge in the functional bed, and the residence time is 35 hours. The composite greenhouse ecological function bed includes the composite greenhouse and its internal ecological function bed. The composite greenhouse is a steel frame structure unit with a length of 4m, a width of 2m, and a height of 2.5m. The ceiling is 150cm long and 60cm wide. Ordinary glass Highly hydrophobic glass coated with 1cm nano-silica hydrophobic material. The bottom of the ecological function bed is a bed reinforcement layer, and an impermeable membrane is laid on the bed reinforcement layer, and a collection and drainage pipe is laid on the impermeability membrane. One end of the collection and drainage pipe is connected to the ventilation pipe, and the other end is connected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com