Anti-corrosion flint clay refractory brick and preparation method thereof

A refractory brick and corrosion-resistant technology, applied in the field of corrosion-resistant coke gemstone refractory bricks and their preparation, can solve the problems of increasing the loss of heat energy, increasing the thermal conductivity of refractory materials, and reducing the thermal insulation effect of refractory materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

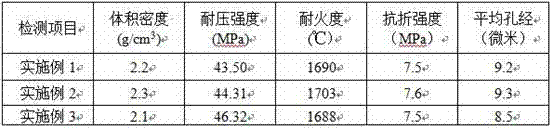

[0026] This embodiment provides a corrosion-resistant scorched gemstone refractory brick, comprising a refractory brick substrate and a high temperature resistant coating sprayed on the surface of the refractory brick substrate; wherein the raw materials of the refractory brick substrate include: 25% large scorched gemstone particles, Hollow glass beads 8%, metakaolin superfine powder 20%, titanium dioxide 3%, expanded graphite 0.5%, fly ash 10%, diatomaceous earth 5.5%, aluminum stearate 6%, and pulp water 22%. The raw materials of the high temperature resistant coating include: polysiloxane 45%, potassium hexatitanate whisker 3%, Mo powder 10%, and ethanol 42%.

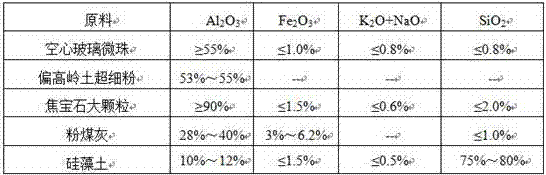

[0027] Wherein, the particle size of the scorched gemstone is 1 mm to 3 mm, the particle size of the hollow glass beads is 0.5 mm to 1 mm, the particle size of the metakaolin ultrafine powder is less than 0.043 mm, and the particle size of the diatomite is less than 0.074mm. The chemical components in each raw materia...

Embodiment 2

[0034] This embodiment provides a corrosion-resistant scorched gemstone refractory brick, which includes a refractory brick matrix and a high temperature resistant coating sprayed on the surface of the refractory brick matrix; wherein the refractory brick matrix includes the following mass percentage materials: Large particles 30%, hollow glass beads 8%, metakaolin ultrafine powder 22%, titanium dioxide 8%, expanded graphite 1.5%, fly ash 8.5%, diatomaceous earth 10%, aluminum stearate 6%, pulp Water 6%. The raw materials of the high temperature resistant coating include: polysiloxane 40%, Mo powder 10%, potassium hexatitanate whisker 3%, and ethanol 47%.

[0035] The preparation method of the corrosion-resistant scorched gem refractory brick described in this embodiment is the same as the preparation method in Example 1. After testing, the density of the corrosion-resistant scorched gem refractory brick prepared in this example is 2.3g / cm 3 .

Embodiment 3

[0037] This embodiment provides a corrosion-resistant scorched gem refractory brick, which includes a refractory brick substrate and a high temperature resistant coating sprayed on the surface of the refractory brick substrate; wherein, the raw material of the refractory brick substrate includes: 25.5% large scorched gem particles , Hollow glass beads 8%, metakaolin ultrafine powder 25%, titanium dioxide 3%, expanded graphite 1.5%, fly ash 5%, diatomaceous earth 5%, aluminum stearate 3%, pulp water 24%; The raw materials for preparing the high temperature resistant coating include: polysiloxane 45%, Mo powder 7%, potassium hexatitanate whisker 1%, and ethanol 47%.

[0038] The preparation method of the corrosion-resistant scorched gem refractory brick described in this embodiment is the same as the preparation method in Example 1. After testing, the density of the corrosion-resistant scorched gem refractory brick prepared in this example is 1.9g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com