Soft magnetic ferrite material with high magnetic permeability and method for preparing soft magnetic ferrite material

A technology of soft magnetic ferrite and high magnetic permeability, which is applied in the field of soft ferrite materials and its preparation, can solve the problems of wide frequency range, non-reflection, and non-reflection, etc., and achieve high-frequency anti-interference ability, Wide frequency and wide temperature magnetic permeability, the effect of small signal transmission distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

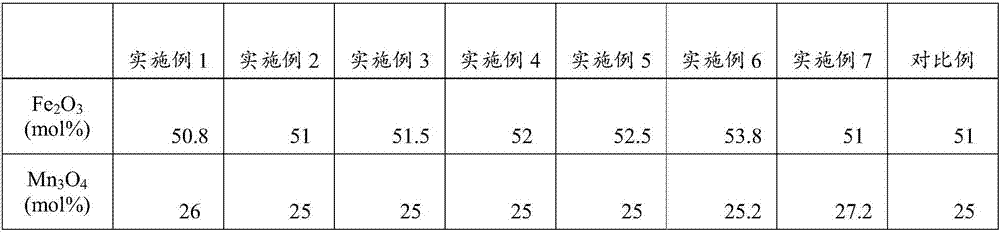

Embodiment 1

[0040] The preparation method of high magnetic permeability soft ferrite material in the embodiment 1 of the present invention, described method comprises the following steps:

[0041] (1) Mix the components in the main component to obtain ball milling material A, add deionized water to ball milling material A and carry out ball milling to obtain slurry A with an average particle diameter of 0.9 μm; wherein, ball milling material A and deionized water The weight ratio of ball abrasive A to steel ball is 1:1.1, the weight ratio of ball abrasive A to steel ball is 1:3, the time of ball milling is 80min, and the diameter of steel ball is 7mm;

[0042] (2) The slurry A obtained in step (1) was pre-fired at a temperature of 850° C. for 5 hours to obtain powder A; wherein, in powder A, the synthesis degree of spinel was 10%, and ball mill B and The weight ratio of ionized water is 1:1, the weight ratio of ball abrasive A and steel ball is 1:5, the time of ball milling is 60min, and ...

Embodiment 2

[0047] The preparation method of high magnetic permeability soft ferrite material in the embodiment 2 of the present invention, described method comprises the following steps:

[0048] (1) Mix the components in the main component to obtain ball milling material A, add deionized water to ball milling material A and carry out ball milling to obtain slurry A with an average particle diameter of 1.2 μm; wherein, ball milling material A and deionized water The weight ratio of the ball abrasive A to the steel ball is 1:1.1, the weight ratio of the ball abrasive A to the steel ball is 1:3, the ball milling time is 100min, and the diameter of the steel ball is 7mm;

[0049] (2) Pre-fire the slurry A obtained in step (1) at a temperature of 950° C. for 3 hours to obtain powder A; wherein, in powder A, the synthesis degree of spinel is 25%, and ball mill B and The weight ratio of ionized water is 1:1, the weight ratio of ball abrasive A and steel ball is 1:5, the time of ball milling is...

Embodiment 3

[0054] The preparation method of high magnetic permeability soft ferrite material in embodiment 3 of the present invention, described method comprises the following steps:

[0055] (1) Mix the components in the main component to obtain ball milling material A, add deionized water to ball milling material A and carry out ball milling to obtain slurry A with an average particle diameter of 1.1 μm; wherein, ball milling material A and deionized water The weight ratio of ball abrasive A to steel ball is 1:1.1, the weight ratio of ball abrasive A to steel ball is 1:3, the time of ball milling is 90min, and the diameter of steel ball is 7mm;

[0056] (2) The slurry A obtained in step (1) was pre-fired at a temperature of 900° C. for 4 hours to obtain powder A; wherein, in powder A, the synthesis degree of spinel was 20%, and ball mill B and The weight ratio of ionized water is 1:1, the weight ratio of ball abrasive A and steel ball is 1:5, the time of ball milling is 70min, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com