High glass transition temperature hole injection material and its preparation and application

A hole injection material, transition temperature technology, applied in the preparation of organic compounds, preparation of aminohydroxy compounds, organic chemistry, etc., can solve the requirements of high solubility of materials, thermal stability can not meet the application requirements of OLED devices, glass problems such as low transition temperature, to achieve the effects of good solubility, good hole transport ability, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

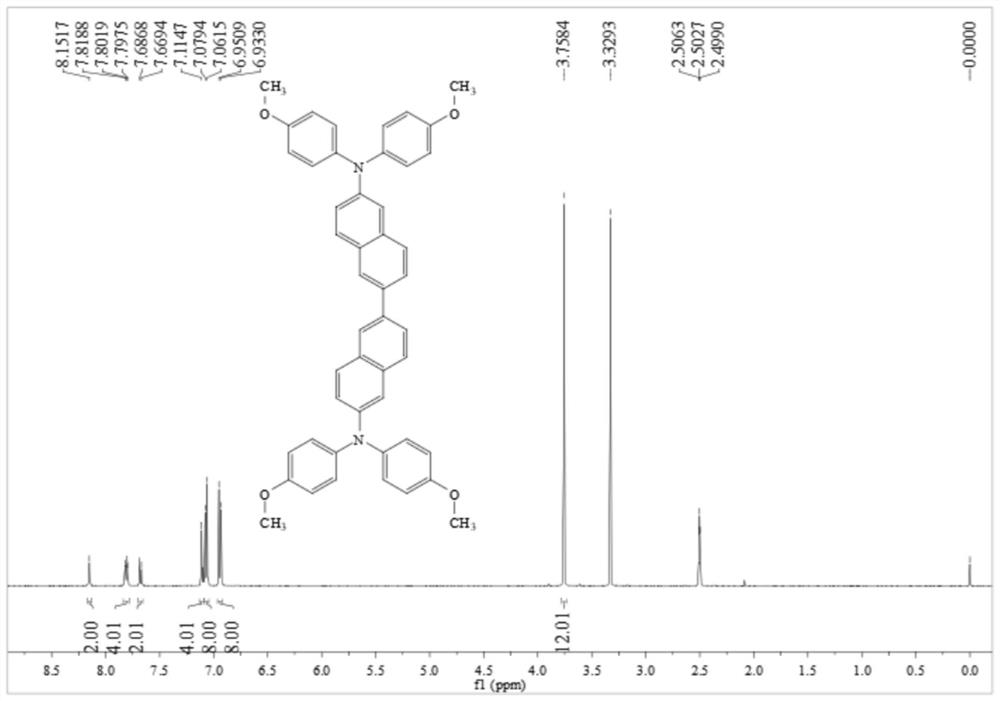

[0054] The structural formula of the hole injection material of this embodiment is specifically as follows:

[0055]

[0056] The preparation method of the hole injection material XL1 with a high glass transition temperature in this embodiment includes the following steps:

[0057] Step 1: Preparation of 6-bromo-N,N-bis(4-methoxyphenyl)-2-naphthylamine (compound 1), the reaction equation is as follows:

[0058]

[0059] Dissolve p-iodoanisole (15g, 0.064mol) and 6-bromo-2-naphthylamine (3.3g, 0.015mol) in 120ml of anhydrous toluene, and quickly add CuI (0.89g, 4.67mmol) under nitrogen atmosphere, 1,10-Phenanthroline (1.232g, 6.83mmol) and sodium tert-butoxide (7g, 75mmol) were heated to 120°C, reacted for about 48h, concentrated to remove toluene, added dichloromethane and distilled water for extraction (dichloromethane and The volume ratio of distilled water is 1:1), the organic layer is dried over anhydrous magnesium sulfate, filtered, concentrated under reduced press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com