Aryl sulfonamide tertiary amine compound synthesizing method

A technology of arylsulfonyl tertiary amide and synthesis method, which is applied in the preparation of sulfonic acid amide, the formation/introduction of sulfonyl group/sulfinyl group, organic chemistry, etc., can solve the problem of large-scale preparation and many reaction steps that are not suitable for industrialization. problem, to achieve the effect of low cost, convenient operation and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

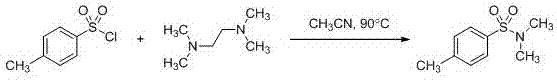

[0022] Embodiment 1, the synthesis of N,N-dimethyl-4-methylbenzenesulfonamide

[0023] Use a flame-dried 50ml two-neck flask, replace the nitrogen three times, use a syringe to dissolve p-toluenesulfonyl chloride (190mg, 1mmol) in acetonitrile (3ml) into the cooled reaction flask, heat the acetonitrile solution to reflux Finally, dissolve N,N,N,N-tetramethylethylenediamine (139mg, 1.2mmol) in 3ml of anhydrous acetonitrile, and slowly add it dropwise to the reaction bottle filled with p-toluenesulfonyl chloride with a syringe , then reacted for 1 hour under acetonitrile reflux, removed the heating, evaporated the solvent under reduced pressure, and separated by flash column chromatography to obtain 183 mg of the product, with a yield of 92%. Its synthetic formula is as follows:

[0024]

[0025] Spectral data: 1 H NMR (600 MHz, CDCl 3 ) δ (ppm): 7.66 (d, J = 8.2 Hz, 2H), 7.33(d, J = 8.0 Hz, 2H), 2.68 (s, 6H), 2.43 (s, 3H); 13 C NMR (151 MHz, CDCl 3 ) δ (ppm): 143.4,...

Embodiment 2

[0026] Embodiment 2, the synthesis of N, N-diethyl-p-toluenesulfonamide

[0027] Use a flame-dried 50ml two-neck flask, replace the nitrogen three times, use a syringe to dissolve p-toluenesulfonyl chloride (190mg, 1mmol) in acetonitrile (3ml) into the cooled reaction flask, heat the acetonitrile solution to reflux Finally, dissolve N,N,N,N-tetraethylethylenediamine (206mg, 1.2mmol) in 3ml of anhydrous acetonitrile, and slowly add it dropwise to the reaction bottle containing p-toluenesulfonyl chloride with a syringe , then reacted for 1 hour under acetonitrile reflux, removed the heat, evaporated the solvent under reduced pressure, and separated by flash column chromatography to obtain 197 mg of the product with a yield of 87%. Its synthetic formula is as follows:

[0028]

[0029] Spectral data: 1 H NMR (600 MHz, CDCl 3 ) δ (ppm): 7.68 (d, J = 8.2 Hz, 2H), 7.27(d, J = 8.0 Hz, 2H), 3.21 (q, J = 7.2 Hz, 4H), 2.41 (s, 3H), 1.11 (t, J = 7.1Hz, 6H); 13 C NMR (151 M...

Embodiment 3

[0030] Embodiment 3, N, the synthesis of N-dipropyl p-toluenesulfonamide

[0031] Use a flame-dried 50ml two-neck flask, replace nitrogen three times, use a syringe to dissolve p-toluenesulfonyl chloride (190mg, 1mmol) in acetonitrile (3ml) into the cooled reaction flask, heat the acetonitrile solution to reflux Finally, dissolve N,N,N,N-tetraisobutylethylenediamine (273mg, 1.2mmol) in 3ml of anhydrous acetonitrile, and slowly add it dropwise to the reaction mixture containing p-toluenesulfonyl chloride bottle, then reacted for 1 hour under acetonitrile reflux, removed the heat, evaporated the solvent under reduced pressure, and separated by flash column chromatography to obtain 216 mg of the product, with a yield of 85%. Its synthetic formula is as follows:

[0032]

[0033] Spectral data: 1 H NMR (600 MHz, CDCl 3 ) δ (ppm): 7.68 (d, J = 8.3 Hz, 2H), 7.27(d, J = 16.4 Hz, 2H), 3.05 (dd, J= 8.5, 6.9 Hz, 4H), 2.41 (s, 3H), 1.59 –1.49 (m, 4H), 0.86 (t, J = 7.4 Hz, 6H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com