A flame-retardant multi-layer coating anti-corrosion system and its construction method

A construction method and a flame-retardant technology, which is applied in the direction of anti-corrosion coatings, flame-retardant fibers, coatings, etc., can solve the absolute problems of poor anti-fouling performance and weather resistance, anti-corrosion system does not have flame-retardant function, and difficult to guarantee quality Controllable and other issues, to achieve good anti-corrosion effect, good construction tolerance and adaptability, and long-lasting anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

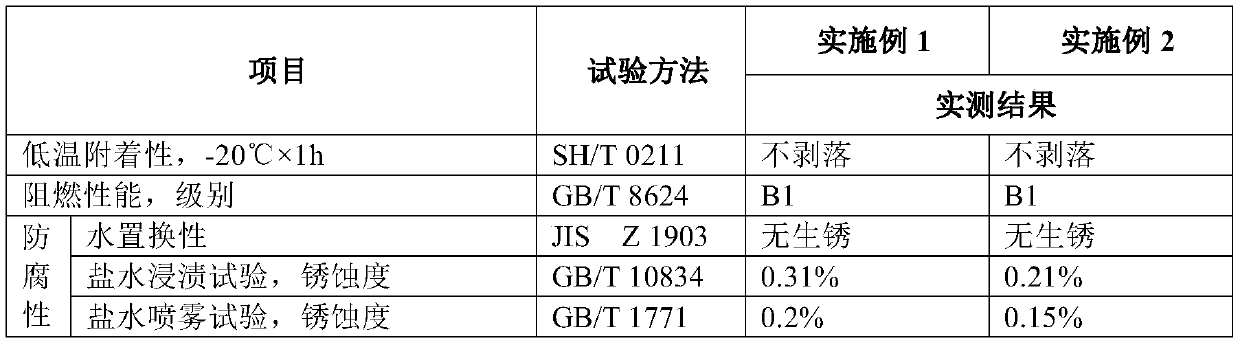

[0046] The flame-retardant anti-corrosion belt is composed of the following components in mass fractions: 7-11% flame-retardant non-woven fabric, 25-35% vegetable oil base oil, 11-15% silicone resin, 1-2% antioxidant, Bacteria 4~8%, hydrogenated castor oil derivatives 3~7%, soybean lecithin 4~6%, fumed silica 3~7%, pyrophyllite powder 8~12%, brucite powder 6~10%, Metal corrosion inhibitor 5-10%. The preparation method of the flame-retardant anti-corrosion belt includes: a. Combining vegetable oil base oil, silicone resin, antioxidant, sterilant, hydrogenated castor oil derivative, soybean lecithin, fumed silica, pyrophyllite powder, Brucite powder and metal corrosion inhibitor are added to the reaction kettle in sequence, and the immersion solution is obtained after high-speed stirring at 80℃~120℃ for 60min~90min, and the immersion solution is discharged into the dipping tank; b. After unwinding, the non-woven fabric is immersed in the dipping tank and maintained at a running ...

Embodiment 1

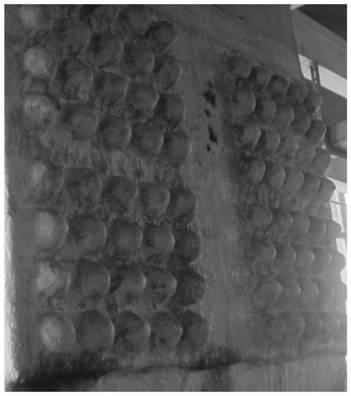

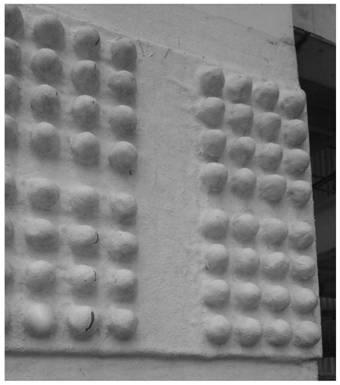

[0056] A construction method of a flame-retardant multi-layer coating anticorrosive system includes the following steps:

[0057] (1) Determination of the construction location area: According to the size and shape of the anti-corrosion construction part of the "H" bolt joint, the bolt connection and the extension of 5-20cm in all directions are the construction area, that is, the protective cover coverage area. The construction area should be extended to the corners. Another facade.

[0058] (2) Surface treatment of steel structure: first clean and polish the surface of the metal structure to be protected. The surface treatment level is not less than St 2.0, and there is no steel thorns, attachments, and obvious bubbling.

[0059] (3) Apply anti-corrosion paste: evenly apply a strip of anti-corrosion paste on the surface of the metal structure processed in step (2), and the amount of the anti-corrosion paste is 0.2L / m 2 .

[0060] (4) Wrap flame-retardant anti-corrosion tape: wrap 1 ...

Embodiment 2

[0070] A construction method of a flame-retardant multi-layer coating anticorrosive system includes the following steps:

[0071] (1) Determination of the construction location area: According to the size and shape of the anti-corrosion construction part of the "H" bolt joint, the bolt connection and the extension of 5-20cm in all directions are the construction area, that is, the protective cover coverage area. The construction area should be extended to the corners. Another facade.

[0072] (2) Surface treatment of steel structure: first clean and polish the surface of the metal structure to be protected. The surface treatment level is not less than St 2.0, and there is no steel thorns, attachments, and obvious bubbling.

[0073] (3) Apply anti-corrosion paste: evenly apply a strip of anti-corrosion paste on the surface of the metal structure processed in step (2), and the amount of the anti-corrosion paste is 1L / m 2 .

[0074] (4) Wrap flame-retardant anti-corrosion tape: wrap 1 la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com