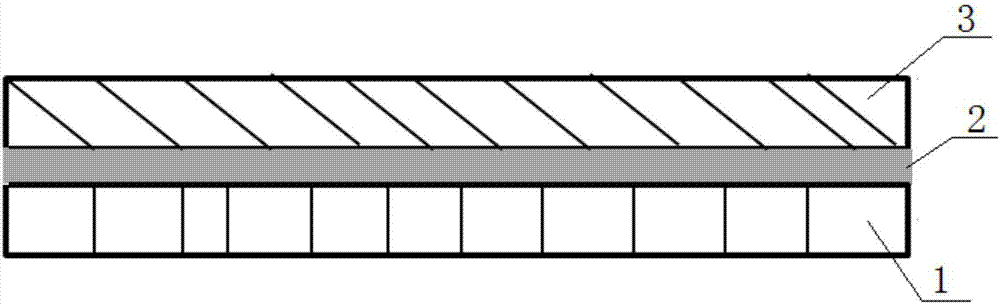

Regenerable antibacterial protective fabric and preparation method thereof

A fabric and protective layer technology, applied in the field of medical textile materials, can solve the problems of poor air permeability and moisture permeability, unable to meet the wearing needs of medical personnel, insufficient uniformity of fabric protection, etc., to achieve good oil resistance and improve film-forming properties , good film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

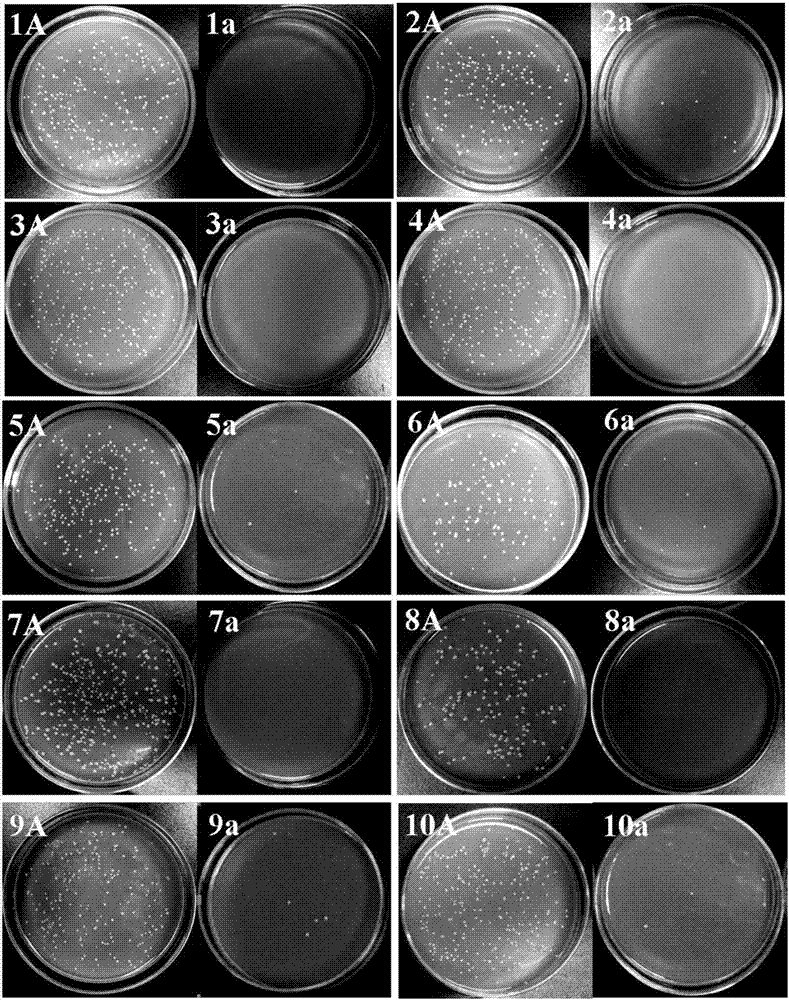

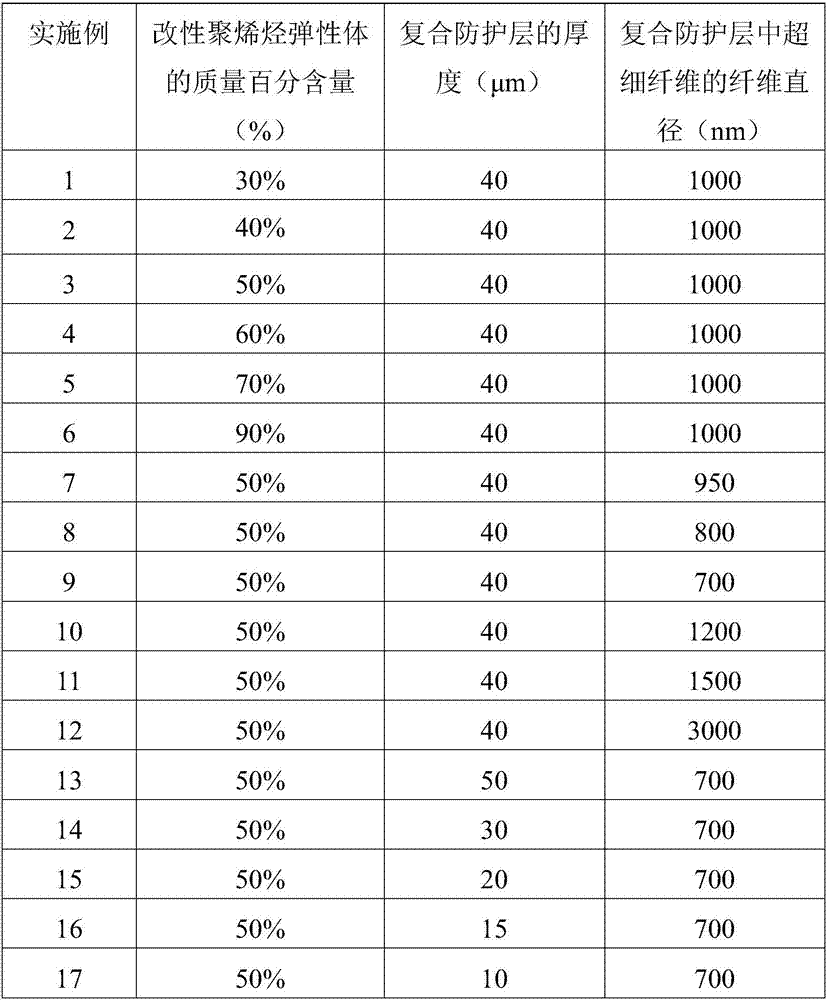

Examples

preparation example Construction

[0035] The invention discloses a method for preparing a regenerable antibacterial protective fabric. The preparation process includes the following steps:

[0036] 1) Preparation of modified polyolefin elastomer masterbatch: blend polyolefin elastomer masterbatch with N-(3-dimethylaminopropyl) methacrylamide, remelt and extrude to obtain modified polyolefin elastomer body masterbatch;

[0037] 2) Preparation of superfine fiber suspension: take modified polyolefin elastomer masterbatch and polyurethane elastomer masterbatch, mix with cellulose acetate butyrate, and prepare superfine fiber by melt coextrusion phase separation method, Then disperse the ultrafine fiber into the water phase through high-speed shearing to prepare the ultrafine fiber suspension;

[0038] 3) Preparation of elastic polyurethane ultrafine fiber suspension: take polyurethane elastomer masterbatch and cellulose acetate butyrate blend, prepare elastic polyurethane ultrafine fiber by melt coextrusion phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com