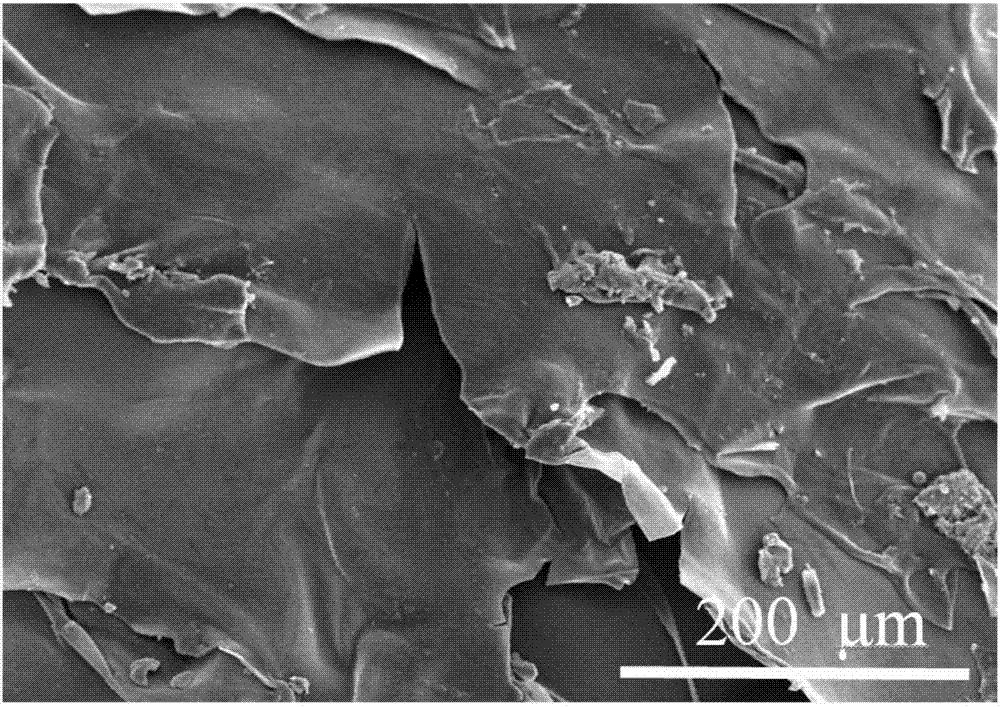

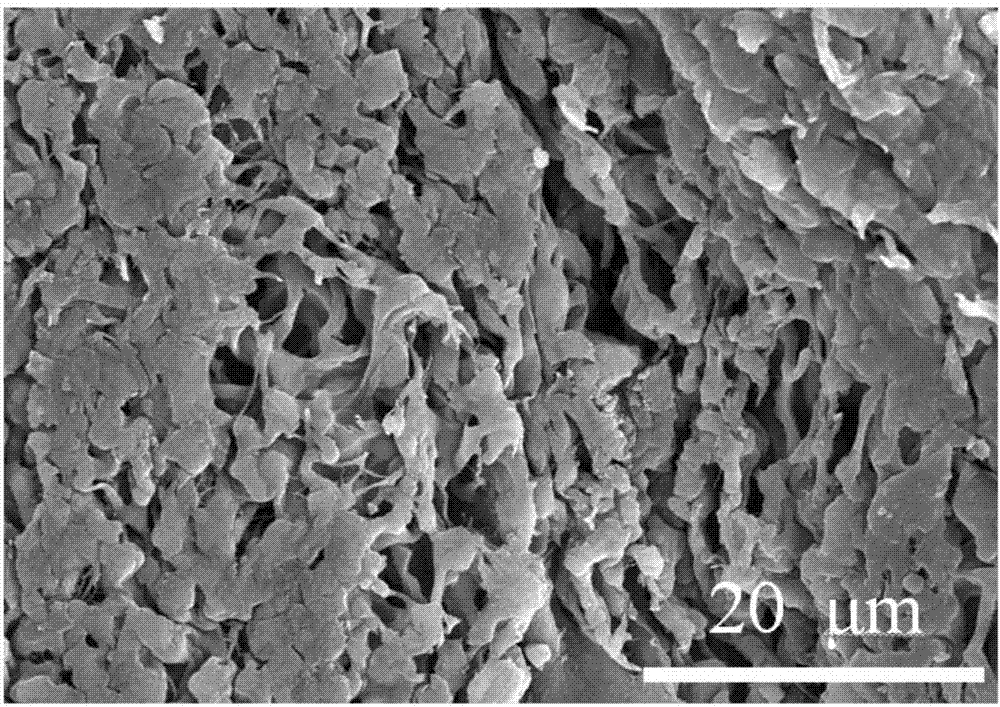

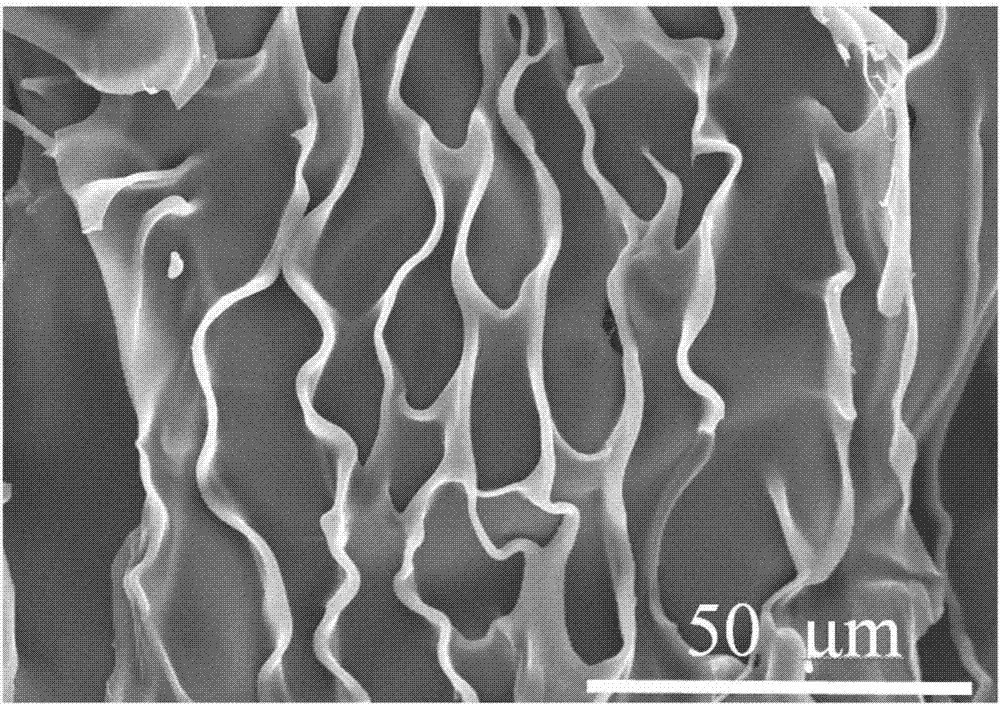

Biomass based network-like porous composite material and preparation method thereof

A reticular porous, composite material technology, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the problems of poor cycle performance and weak adsorption force of composite materials, achieve low cost, improve adsorption force, Simple process and environmentally friendly results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a biomass-based porous composite material, comprising the following steps,

[0033] (1) Preparation of CMC gel

[0034] First mix 0.4889g CMC with 10mL H 2 O was slowly added into a 250mL round-bottomed flask in 3 times, and the device was sealed and placed in a water bath at 50°C for 25min with mechanical stirring at a speed of 200rpm / min, which was recorded as CMC gel.

[0035] (2) Preparation of BTC solution

[0036] Dissolve 0.4889g of BTC in 6mL of absolute ethanol, and ultrasonically dissolve it for 5 minutes, and record it as BTC solution;

[0037] (3) Preparation of composite materials of CMC-BTC

[0038] Add the BTC mixed solution dropwise into the CMC gel, and stir it mechanically for 20 min. Pour the mixed solution into a polytetrafluoroethylene mold inserted with a 30° beveled copper sheet, seal it with a plastic wrap, place it in a container containing liquid nitrogen at a rate of 0.5 cm / s, freeze it for 5 minutes, and then quickl...

Embodiment 2

[0044] A method for preparing a biomass-based porous composite material, comprising the following steps,

[0045] (1) Preparation of CMC gel

[0046] First mix 4.889g CMC with 100mL H2 O was slowly added to a 250 mL round-bottomed flask in 10 times, and the device was sealed and placed in a water bath at 60 °C for mechanical stirring for 50 min at a rotational speed of 500 rpm / min, which was designated as CMC gel.

[0047] (2) Preparation of BTC solution

[0048] Dissolve 3.85g BTC in 60mL absolute ethanol, ultrasonicate for 10min to fully dissolve it, and record it as BTC solution;

[0049] (3) Preparation of CMC-BTC composites

[0050] The BTC mixed solution was added dropwise to the CMC gel and mechanically stirred for 30 min. Pour the mixed solution into a polytetrafluoroethylene mold with a 10° beveled copper sheet, seal it with plastic wrap, place it in a container containing liquid nitrogen at 0.5cm / s, freeze it for 5 minutes, and quickly put it into freeze-drying. ...

Embodiment 3

[0056] A preparation method of a biomass-based reticulated porous composite material, comprising the following steps:

[0057] (1) Preparation of CMC gel

[0058] First, 0.4889g of CMC and 10mL of H2O were slowly added to a 250mL round-bottomed flask several times, and the device was sealed and placed in a water bath at 55°C for mechanical stirring for 30min at a speed of 300rpm / min, denoted as CMC gel.

[0059] (2) Preparation of BTC solution

[0060] Take 0.385g BTC and dissolve it in 6mL absolute ethanol, ultrasonicate for 3min to make it fully dissolved, and record it as BTC solution;

[0061] (3) Preparation of CMC-BTC composites

[0062] The BTC mixed solution was added dropwise to the CMC gel and mechanically stirred for 30 min. Pour the mixed solution into a polytetrafluoroethylene mold with a 15° beveled iron sheet, seal it with plastic wrap, place it in a container containing liquid nitrogen at 0.6 cm / s, freeze it for 4 minutes, and quickly put it into freeze-dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com