Water-based cleaning-free scaling powder

A no-cleaning and flux technology, applied in the direction of welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as poor stability and insulation performance, poor flux spreading and wettability, etc., to achieve Avoid corrosion, guarantee the original activity, improve the activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

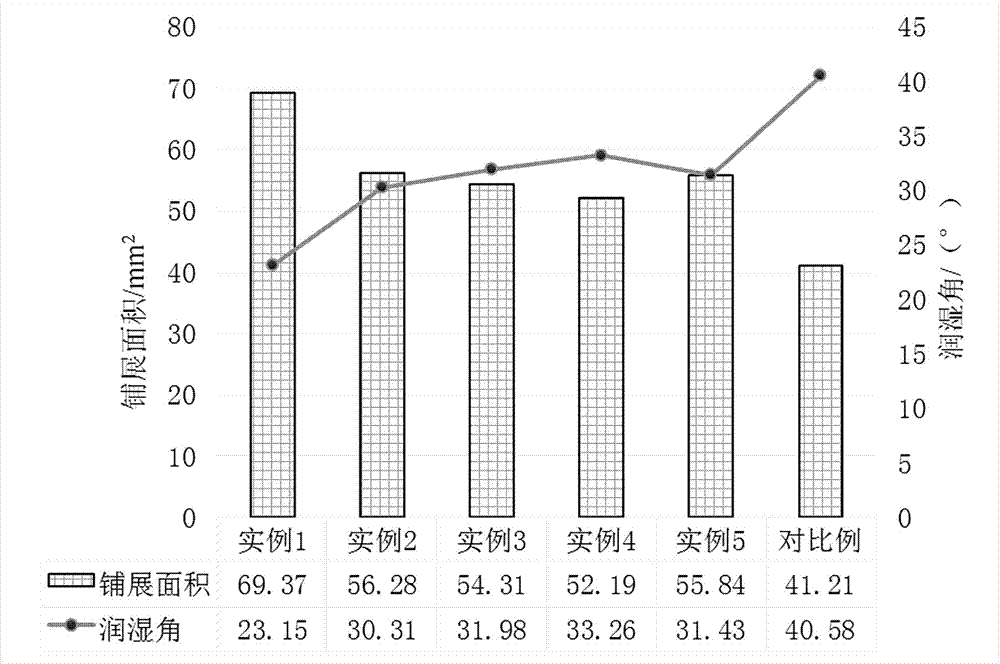

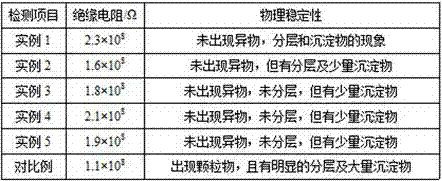

Examples

example 1

[0024] In parts by weight, take 100 parts of deionized water, 4 parts of ethyl ether, 5 parts of aromatic ether, 4 parts of butyl acetate, 4 parts of petroleum resin, 5 parts of terpene resin, and stir at high speed with a stirrer at 1500r / min 5h, get the solvent; in parts by weight, take 15 parts of citric acid, 6 parts of lactic acid, 10 parts of polyaspartic acid, 10 parts of polyallylamine, 10 parts of polyethyleneimine, and stir and mix with a glass rod for 60 minutes. Obtain the active substance; in parts by weight, take 10 parts of surfactant, 8 parts of corrosion inhibitor, 15 parts of thixotropic agent, 20 parts of film-forming aids, 6 parts of antioxidant, and mix with glass rod for 60 minutes to obtain Additives: In parts by weight, take 100 parts of solvent, 15 parts of active material, 8 parts of additives, pour them into the mixer, and pour nitrogen into the mixer at a rate of 80mL / min. Under nitrogen protection, Stir and mix at 800r / min for 5h, discharge and fill...

example 2

[0026] In parts by weight, take 100 parts of deionized water, 4 parts of diethyl ether, 4 parts of butyl acetate, 4 parts of petroleum resin, 5 parts of terpene resin, and stir at high speed with a stirrer at 1500r / min for 5h to obtain the solvent; In parts by weight, take 15 parts of citric acid, 6 parts of lactic acid, 10 parts of polyaspartic acid, 10 parts of polyallylamine, and 10 parts of polyethyleneimine in sequence, stir and mix with a glass rod for 60 minutes to obtain the active substance; In parts by weight, sequentially take 10 parts of surfactant, 8 parts of corrosion inhibitor, 15 parts of thixotropic agent, 20 parts of film-forming aids, 6 parts of antioxidant, stir and mix with a glass rod for 60 minutes to obtain additives; Count, take 100 parts of solvent, 15 parts of active material, 8 parts of additives, pour them into the mixer, pour nitrogen into the mixer at a rate of 80mL / min, and rotate at 800r / min under nitrogen protection Stir and mix for 5 hours, di...

example 3

[0028] In parts by weight, take 100 parts of deionized water, 4 parts of diethyl ether, 5 parts of aromatic ether, 4 parts of butyl acetate in sequence, and stir with a stirrer at a high speed of 1500r / min for 5 hours to obtain the solvent; in terms of parts by weight, Take 15 parts of citric acid, 6 parts of lactic acid, 10 parts of polyaspartic acid, 10 parts of polyallylamine, and 10 parts of polyethyleneimine in sequence, stir and mix with a glass rod for 60 minutes to obtain the active substance; Take 10 parts of surfactant, 8 parts of corrosion inhibitor, 15 parts of thixotropic agent, 20 parts of film-forming aids, 6 parts of antioxidant, stir and mix with a glass rod for 60 minutes to obtain additives; take 100 parts by weight in sequence Part solvent, 15 parts active substance, 8 parts additive, pour into the blender, pour nitrogen into the blender at a rate of 80mL / min, under nitrogen protection, stir and mix at 800r / min for 5h, discharge , Filling, that is, water-bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com